Formwork reciprocating device for stationary magnesite roof board production equipment

A production equipment and fixed technology, applied in the direction of lamination devices, layered products, lamination auxiliary operations, etc., can solve the problems of high labor stress and low efficiency, achieve convenient operation, meet the requirements of use, and realize automatic mechanization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

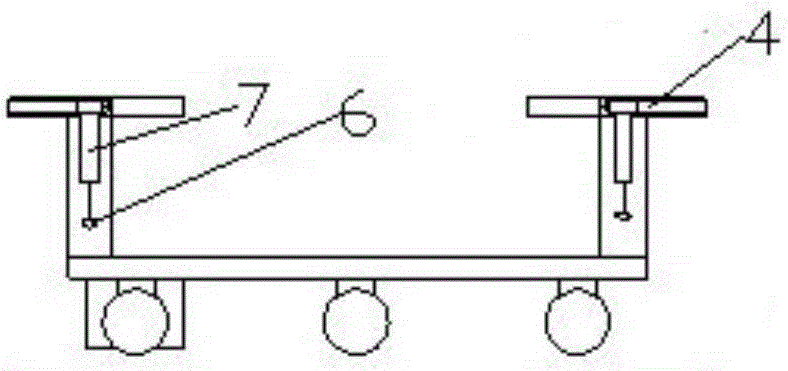

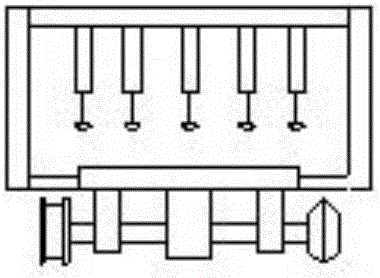

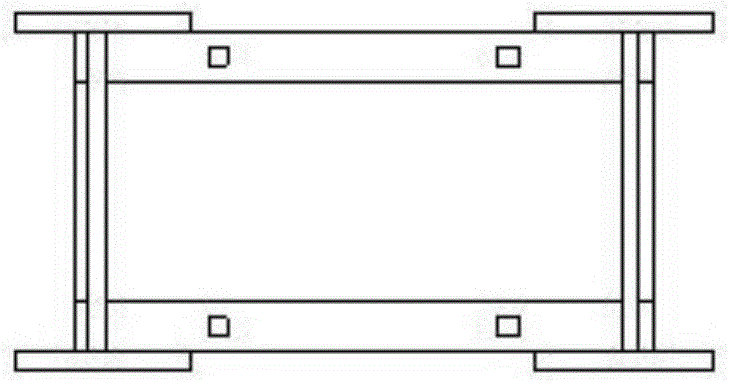

[0016] Stationary magnesite roof plate production equipment formwork reciprocating device, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, it consists of a first guide wheel 2, a second guide wheel 3, a positioning hole 5, a horizontal push-pull cylinder 4, a vertical lifting cylinder 7, a motor and a braking device 8, and a hemispherical pressure head 6. It is characterized in that the positioning hole 5 cooperates with the positioning guide post on the template 9, the hemispherical indenter 6 cooperates with the semicircular groove on the template 9, the horizontal push-pull cylinder 4 moves the vertical lifting cylinder 7 to or away from the top of the template, and the vertical lifting cylinder 7 pushes the hemispherical indenter 6. Press the aluminum-plastic composite film, glass fiber mesh, and flame-retardant foam boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com