High-modulus carbon fiber board and manufacturing method thereof

A carbon fiber sheet, high-modulus technology, applied in the high-modulus carbon fiber sheet and its manufacturing field, can solve problems affecting the functional properties of composite materials, and achieve the effects of accurate manufacturing dimensions, no environmental pollution, and improved working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

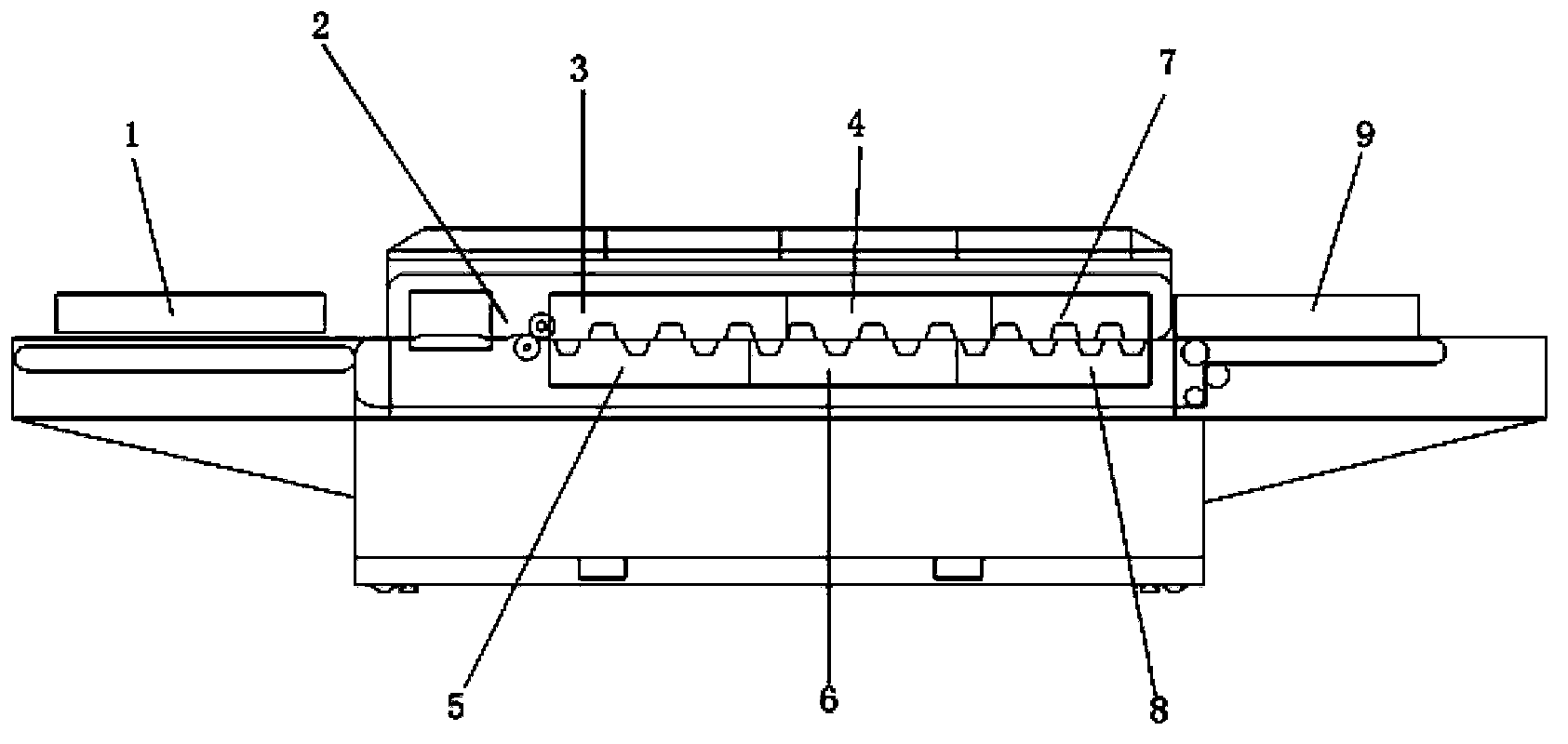

[0051] figure 1 It shows the schematic diagram of the lamination equipment using different temperature zones to control the lamination temperature separately. This structure completely solves the problem of thermal shrinkage and deformation of materials.

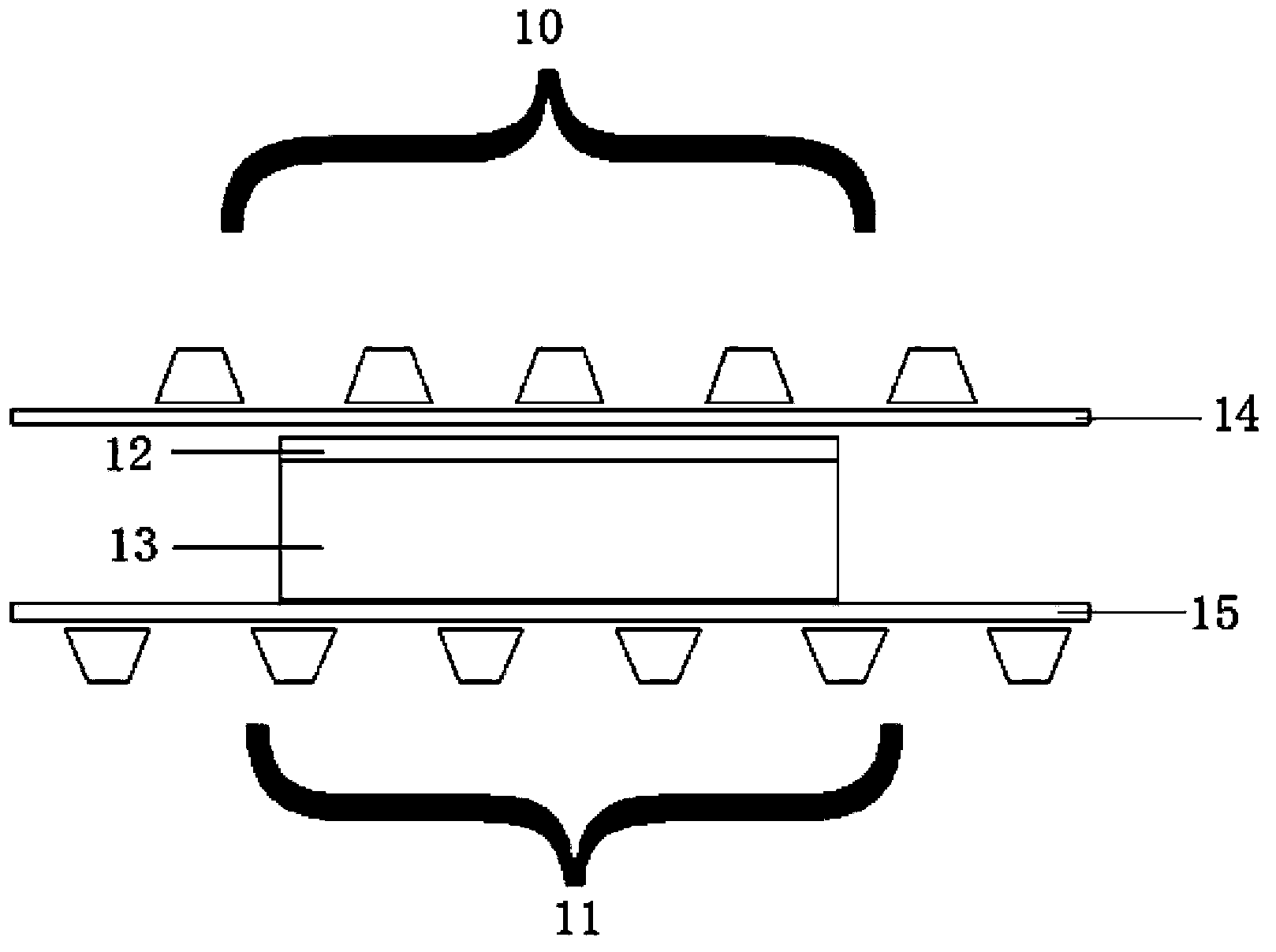

[0052] figure 2 It is a schematic diagram of setting the temperature of the upper and lower temperature zones separately. For materials with different thicknesses, the equipment can set the temperature of the upper and lower temperature zones separately to obtain satisfactory lamination quality.

[0053] image 3 , 4 It is a schematic diagram of one-step compounding of multi-layer materials. Leather, sponge, textile materials, etc. and their adhesive layers can be compounded in one step. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com