A double-head drilling and tapping machine tool

A technology for processing machine tools and double-head drills, which is applied to metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of high protection level requirements of servo transmission mechanisms, complex mechanisms, waste of raw materials, etc., and achieve pipeline layout Convenience, simplified mechanical structure, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

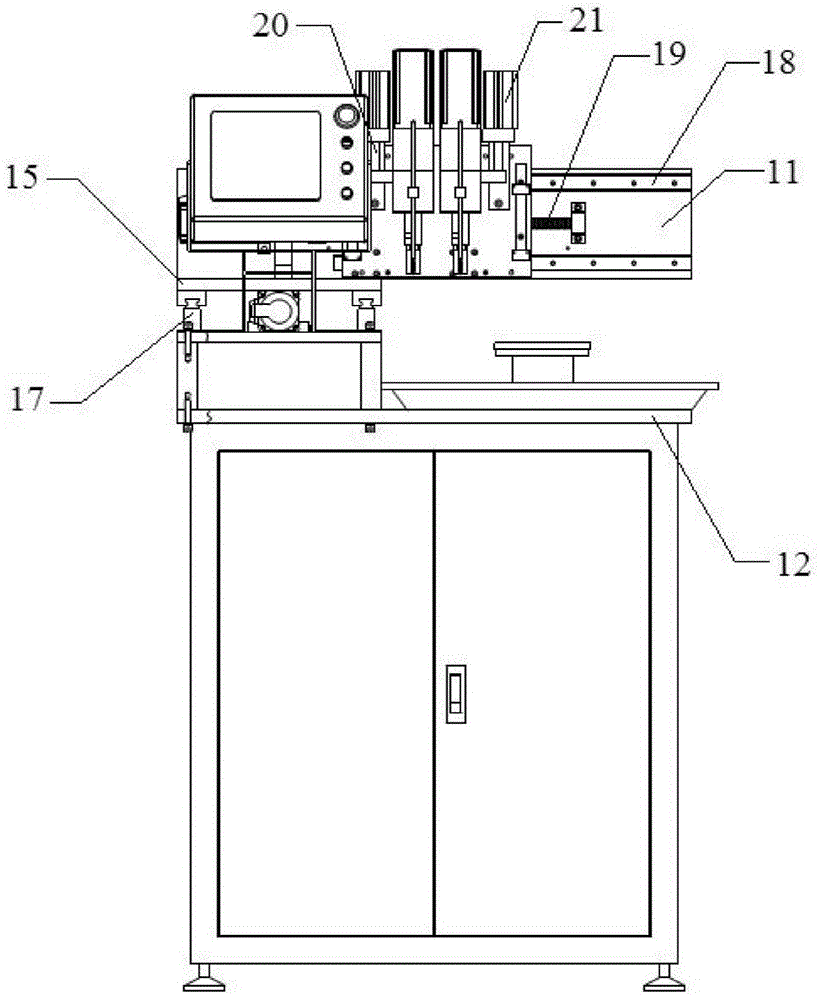

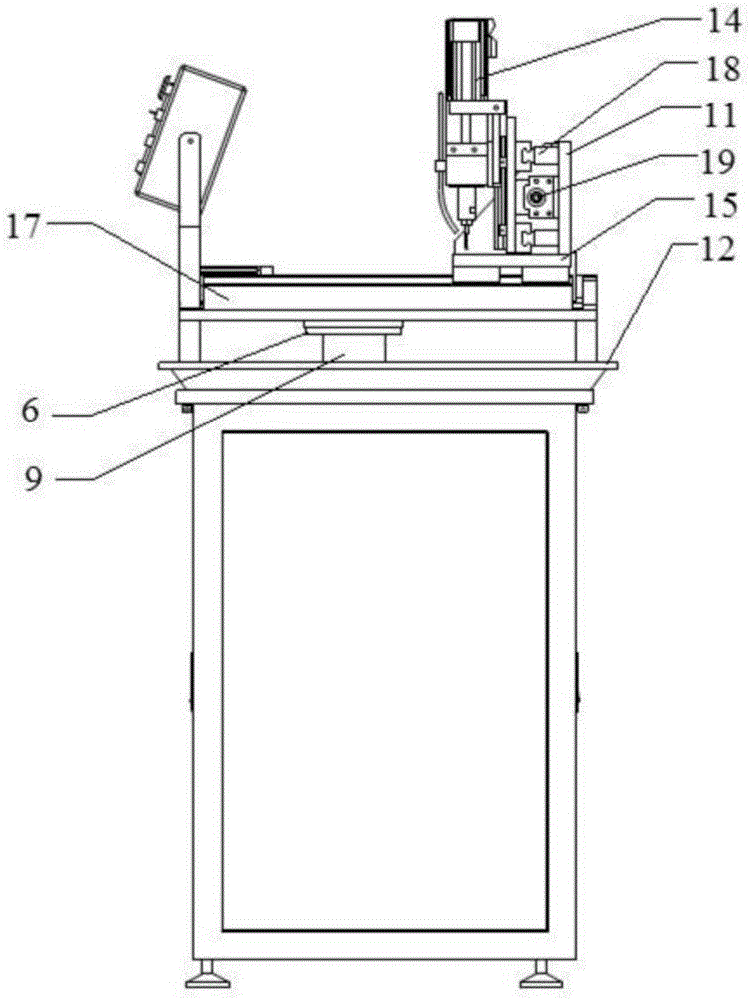

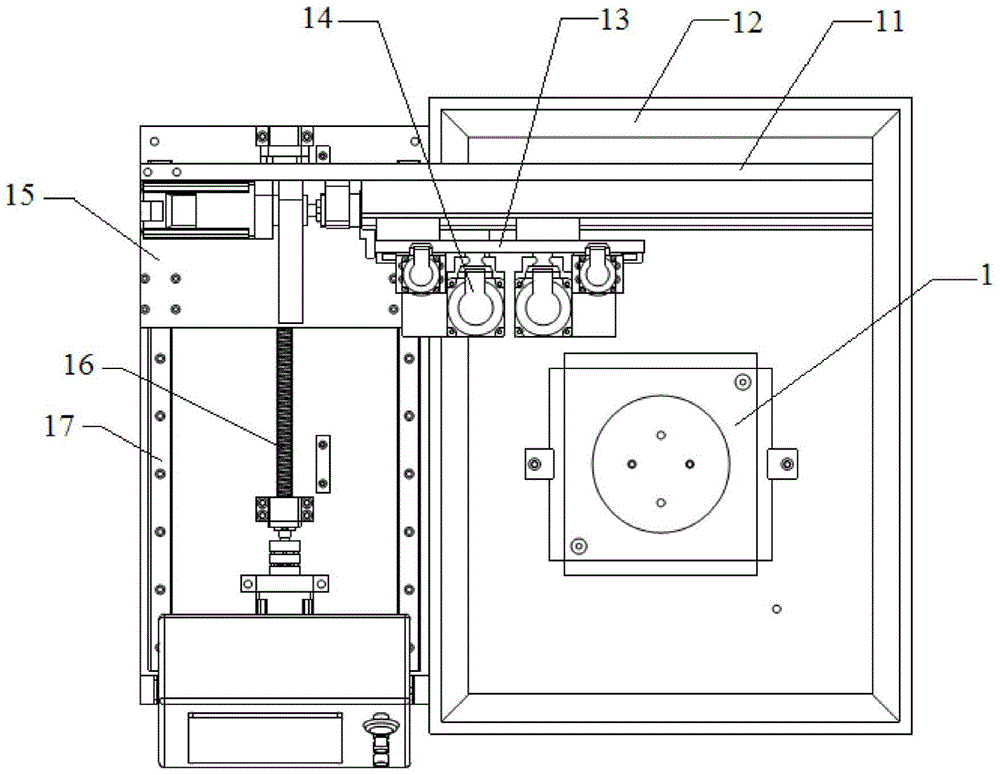

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0035] like figure 1 , figure 2 and image 3 As shown, the present invention provides a double-head drilling and tapping machine tool, which is characterized in that, comprising:

[0036] Workbench 12;

[0037] Floating positioning tool, which is arranged on the workbench 12, and is elastically connected with the workbench 12 laterally, the workpiece to be drilled is fixed on the floating positioning tool, and the hole to be drilled of the workpiece to be drilled is provided with a pit ;

[0038] Two drill bits 14 are arranged side by side above the floating positioning tool and are supported by the workbench 12. The workbench 12 supports the two drill bits 14 along the front-rear direction Y and the left-right direction X through a servo positioning device. and the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com