Horizontal type double-head machining center

A machining center, horizontal technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of accelerating the flow speed of profile processing and difficulty in profile processing flow, etc., to simplify the structure and flow mode, and process flexibly , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

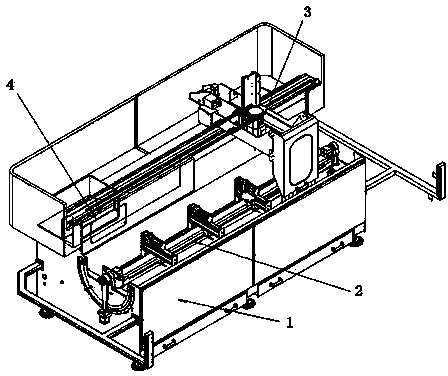

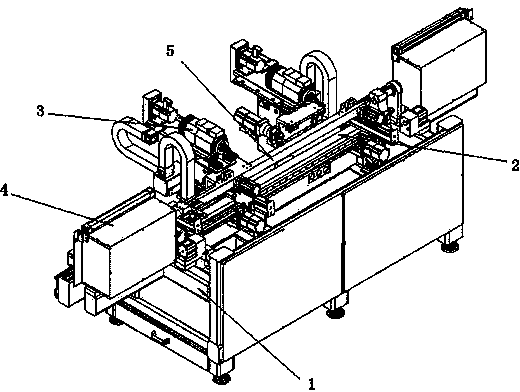

[0050] Such as Figure 2-9 A horizontal double-head machining center shown includes: a bed 1, a rotary table 2, a machine head 3 and a tool box 4; the rotary table 2 is installed on the bed 1, and the machine head 3 is The horizontal machine head is installed on one side of the workbench; the tool box 4 is fixed on the bed (1).

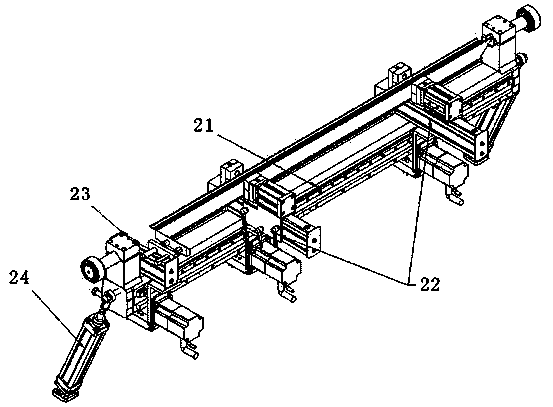

[0051] In this embodiment, the bed 1 includes: a linear guide rail 11, a linear rack 12; the rotary table 2 includes: a beam 21, a fixture 22, a comparison detector 23, and a rotary drive cylinder 24; the comparison detector 23 includes: Support 231, support plate 232, guide shaft 233, spring 234, positioning block 235, magnetic grid 236, displacement sensor 237, servo motor 238, shaft block 239; tool magazine 4 comprises: box body 41, box door 42, handle of a knife And matching tool 43, tool magazine drive cylinder 44.

[0052] The connections of the above components are as follows:

[0053] The machine head (3) performs X-direction reciprocating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com