Fastening system with eccentric

An eccentric, tightening technology, applied in the direction of elements with teeth, connecting members, manufacturing tools, etc., can solve problems such as reducing production costs, and achieve the effect of shortening installation time, shortening installation costs, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

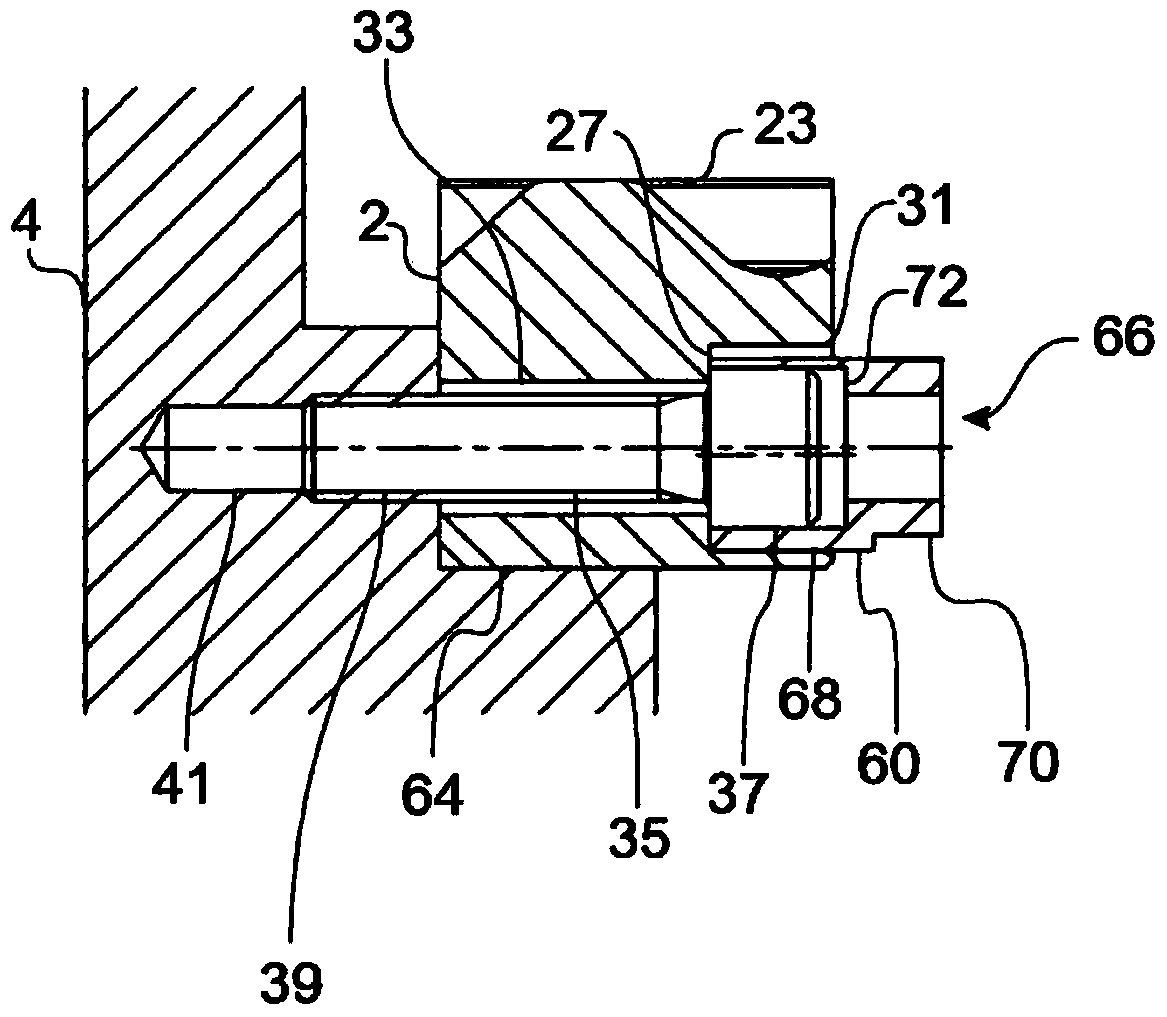

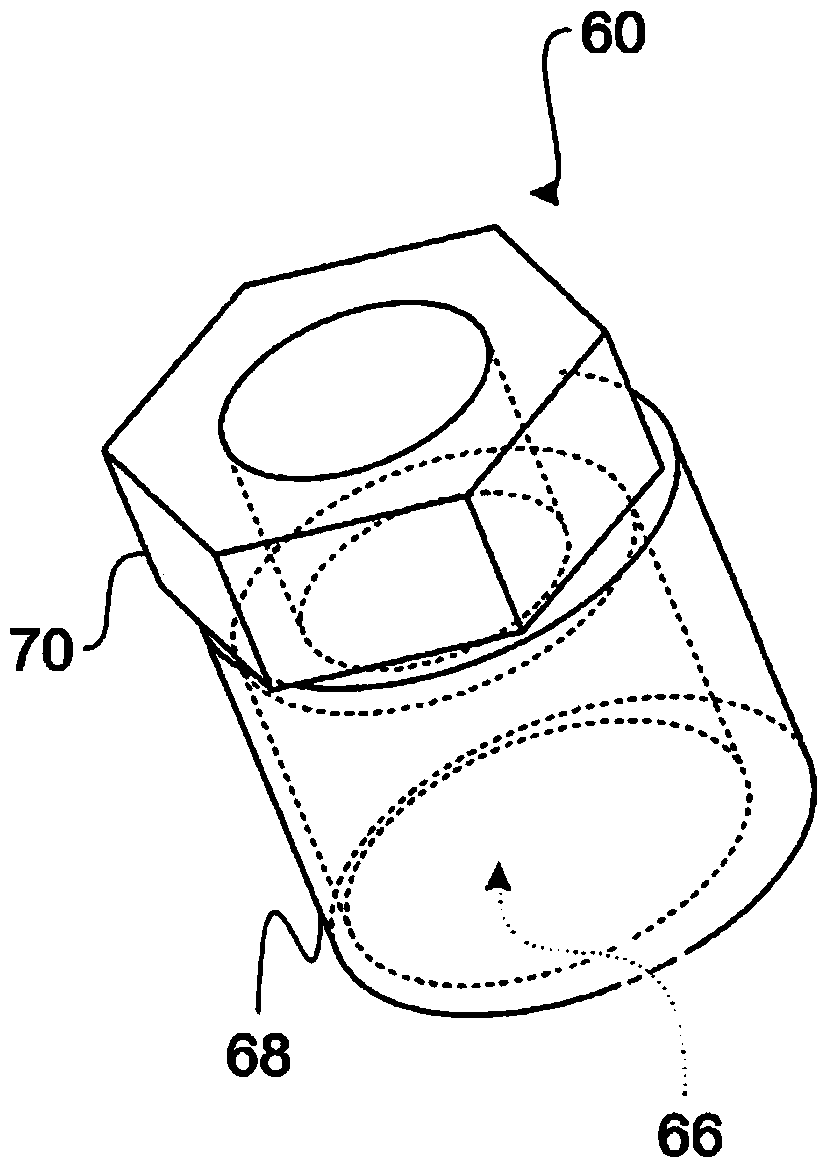

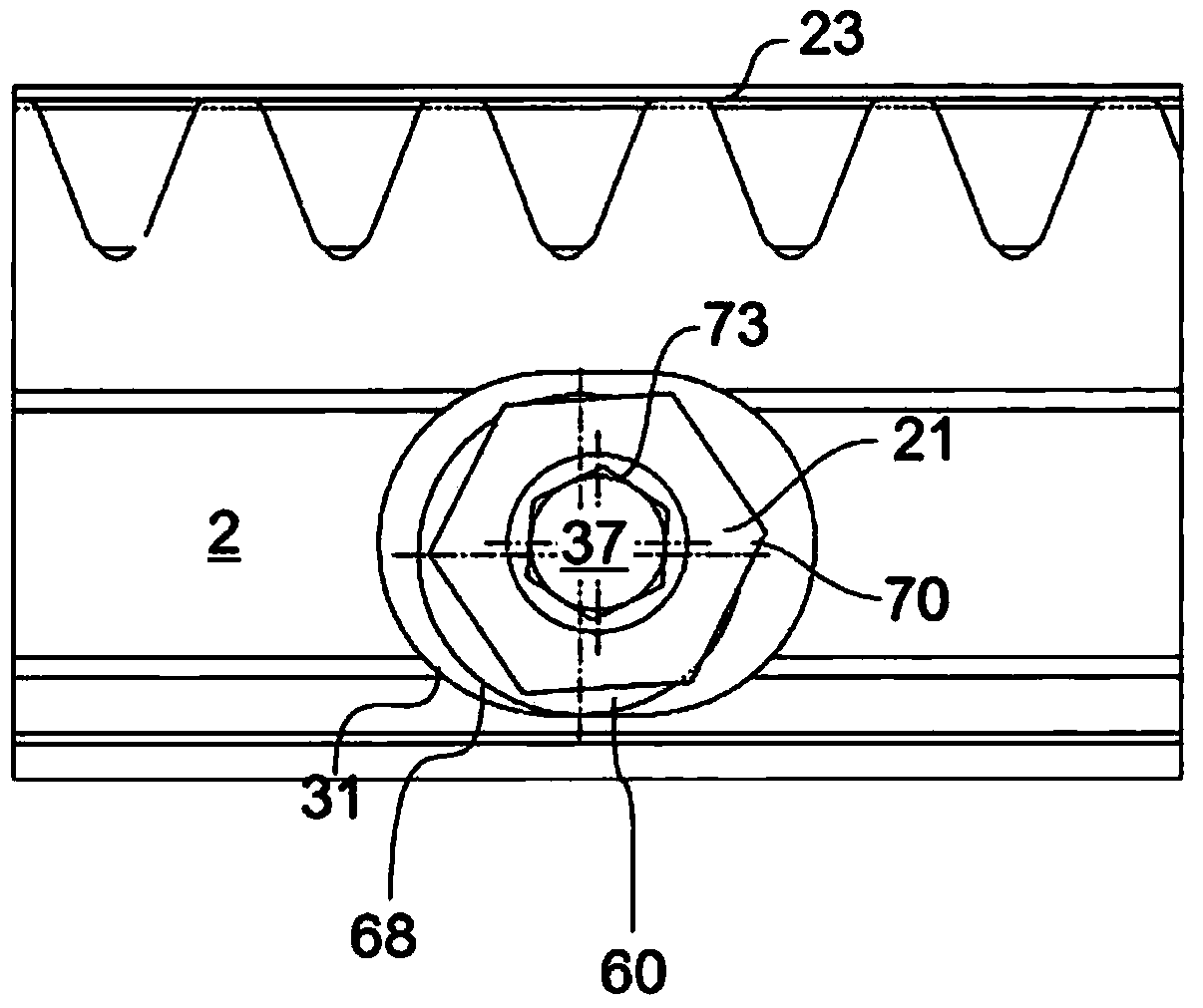

[0035] Exemplary embodiments are described below based on the drawings, wherein the present invention is not limited to these exemplary embodiments; rather, the scope of the present invention is defined by the claims. Figure 1 to Figure 7 An exemplary embodiment or a portion thereof is shown. For the description of all the figures, the same reference numerals are used for corresponding parts, so the description will not be repeated in connection with each individual figure. Some components or parts are the same in different embodiments and therefore will not be repeated in detail.

[0036] figure 1 A cross-section of an embodiment of a fastening system for fastening a linear machine element is shown in section. exist figure 1 In the embodiment, a linear mechanical element 2 in the form of a rack is provided.

[0037] The linear mechanical element 2 comprises obliquely shaped teeth 23 . figure 1 The cross-section of also shows the opening extending through the linear mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com