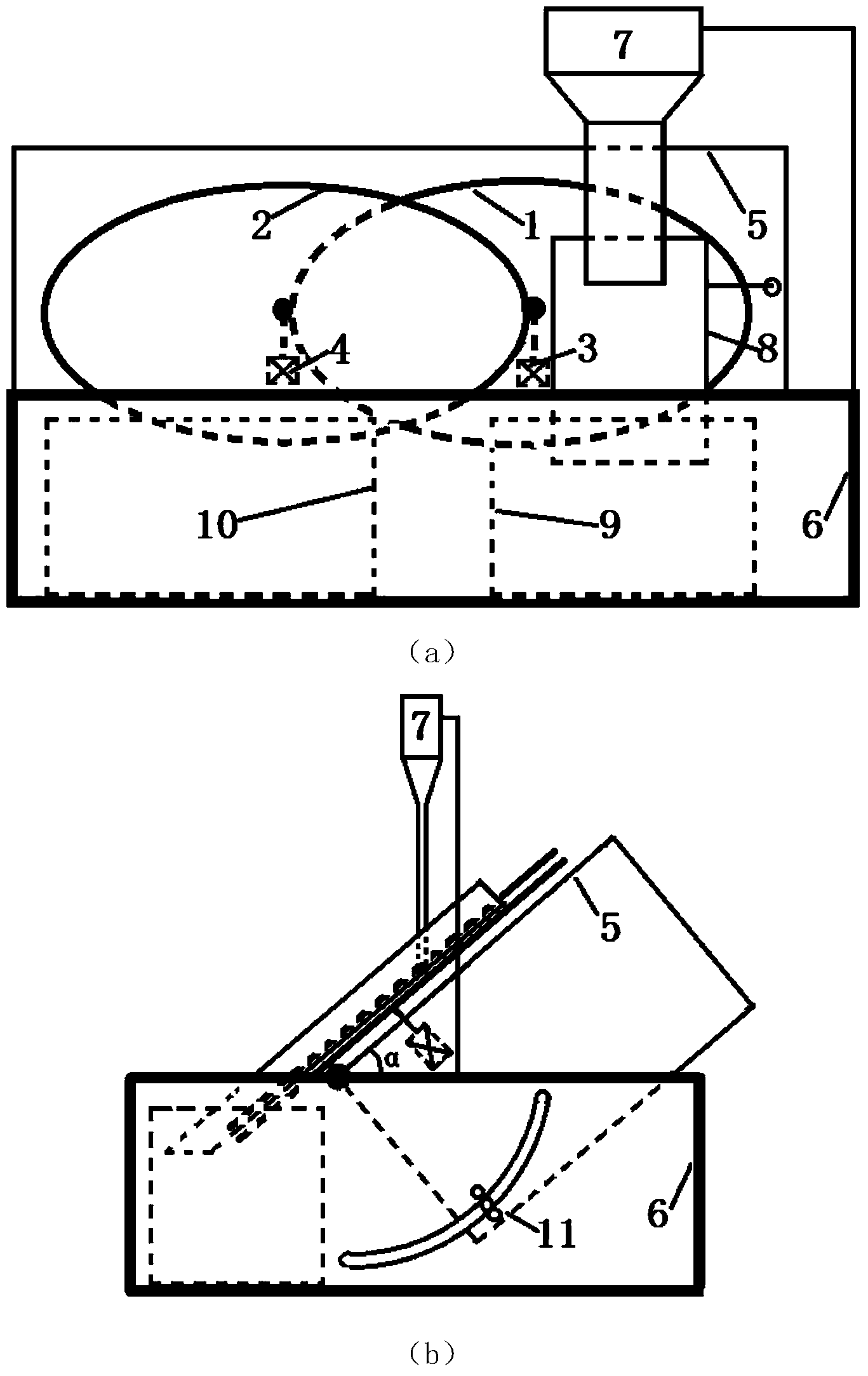

Rotating disc type ball-shaped powder sieving device and operating method

A screening device and technology for spherical powder, applied in the field of rotary disc screening device, to achieve the effect of simplifying the operation process, improving the screening effect and efficiency, and solving the discontinuity problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In the special equipment of this embodiment, the rotating disk is made of stainless steel, the diameter of the disk surface is 50cm, and the surface roughness is Ra3.2. When the inclination angle of the disk surface is 5°, the motor speed is 20 rpm, and the HoCu particle size is 0.30-0.5mm. 2 1 kg of magnetic cold storage material is put into the feeding funnel, and the recovery rate of the spherical powder after one screening is greater than 85%.

Embodiment 2

[0024] In the special equipment of this embodiment, the rotating disk is made of plexiglass, the diameter of the disk surface is 30cm, and the surface roughness is Ra0.2. When the inclination angle of the disk surface is 2°, the motor speed is 40 rpm, and the particle size is 0.154-0.18mm. HoCu 2 1 kg of magnetic cold storage material is put into the feeding funnel, and the recovery rate of the spherical powder after one screening is greater than 85%.

Embodiment 3

[0026] In the special equipment of this embodiment, the rotating disk is made of ceramics, the diameter of the disk surface is 40cm, and the surface roughness is Ra0.5. When the inclination angle of the disk surface is 4°, the motor speed is 15 rpm, and the particle size is 0.18-0.30mm. HoCu 2 1 kg of magnetic cold storage material is put into the feeding funnel, and the recovery rate of the spherical powder after one screening is greater than 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com