Mixing cylinder door adjusting device

A technology of adjusting device and adjusting hole, which is applied in the direction of mixer accessories, dissolving, mixing machines, etc., can solve the problems of time-consuming and laborious, inconvenient maintenance, etc., and achieve the effect of convenient adjustment, reliable use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific embodiments.

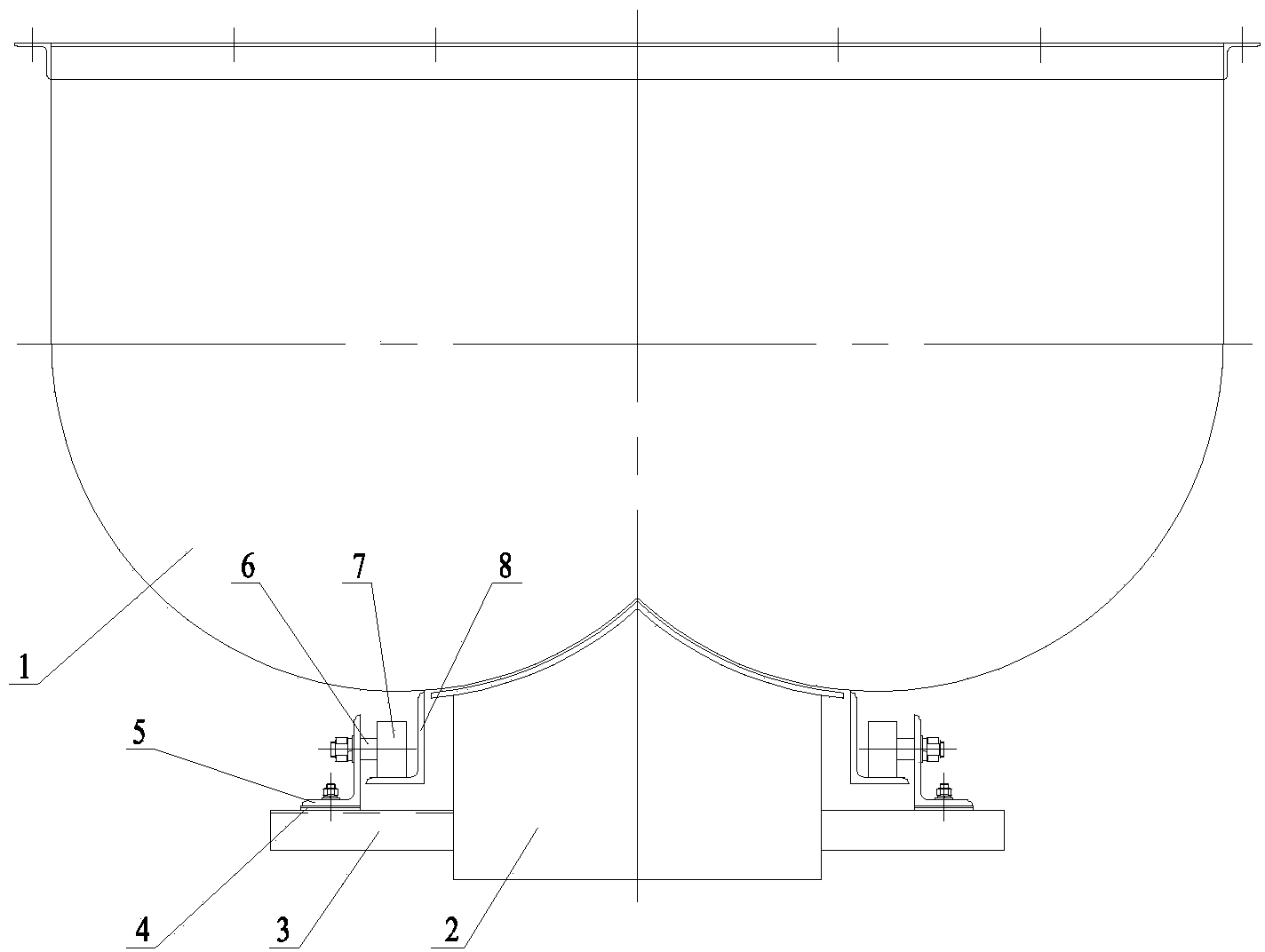

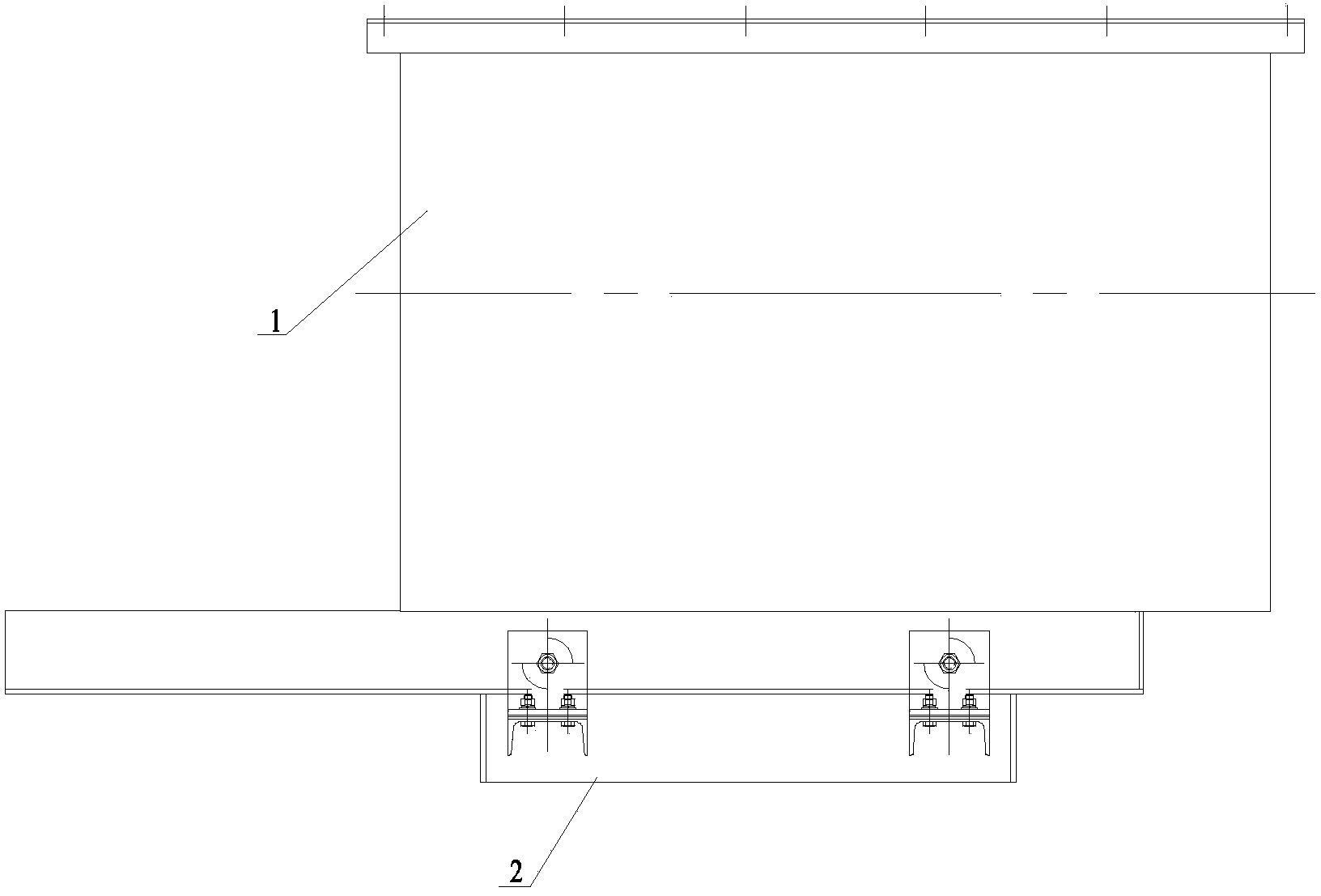

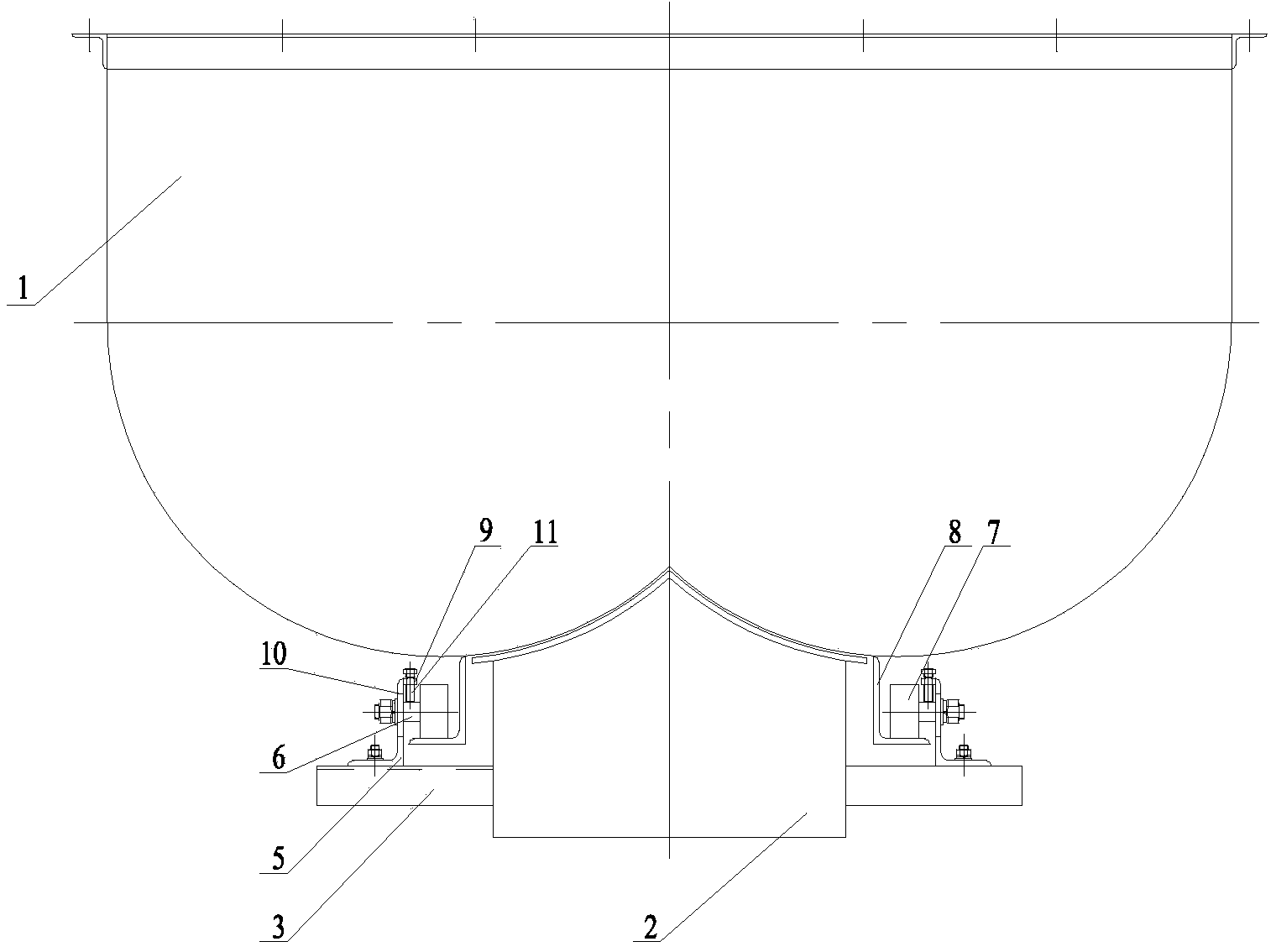

[0012] The mixing cylinder door adjusting device includes mixing cylinder 1, mixing cylinder door 2, channel steel 3, angle steel 5, pulley shaft 6, pulley 7 and guide rail 8. A guide rail 8 is fixed at the bottom end of the mixing cylinder 1, and A channel steel 3 is fixed on the door 2, an angle steel 5 is fixed on the channel steel 3, a pulley 7 is rotatably installed on the pulley shaft 6, and the pulley 7 cooperates with the guide rail 8. The angle steel 5 is provided with an adjustment hole 10 and an adjustment hole 10 It is a waist-shaped hole, the length of the adjusting hole 10 is arranged along the height direction of the angle steel 5. The pulley shaft 6 is fixed in the adjusting hole 10, the adjusting nut 9 is fixed on the angle steel 5, and the adjusting nut 9 is screwed An adjusting bolt 11 is connected, and the bottom end of the adjusting bolt 11 abuts against t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com