Multi-layer back electrode for a photovoltaic thin-film solar cell, use of the same for producing thin-film solar cells and modules, photovoltaic thin-film solar cells and modules containing the multi-layer back electrode and method for the production thereof

A solar cell, back electrode layer technology, applied in photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as high production costs, and achieve the effect of good quantum throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

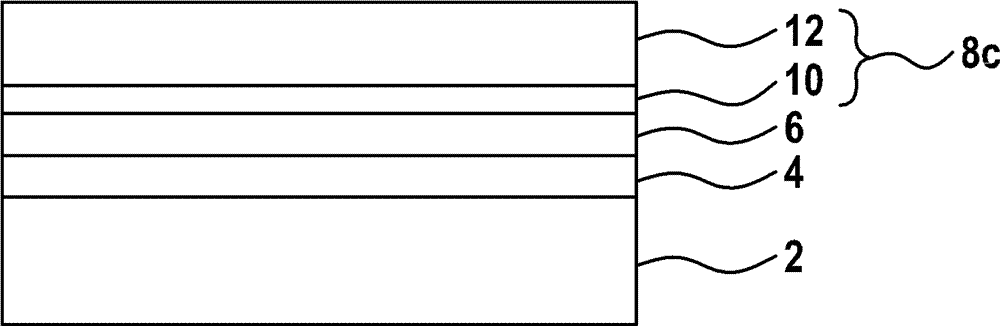

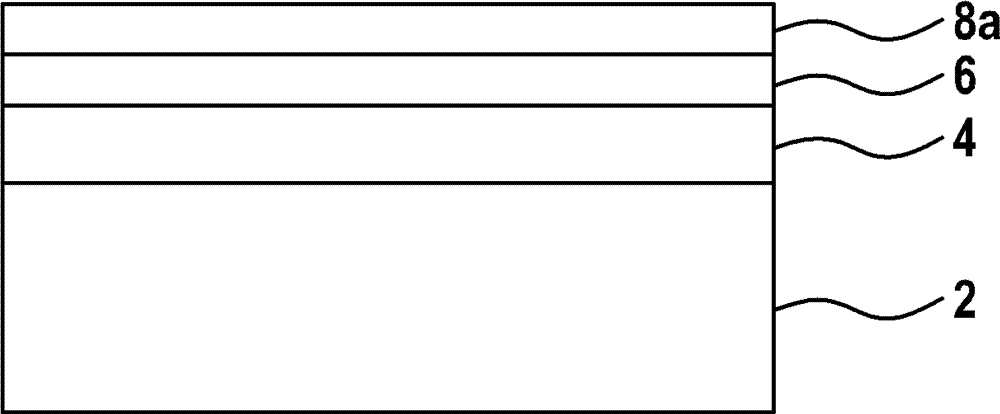

[0048] exist figure 1 In the embodiment of the multilayer back electrode 1 according to the invention shown in , there is a bulk back electrode layer 4 made of molybdenum on a substrate layer 2 , for example a glass substrate. On the block back electrode layer 4 there is a bidirectionally acting conductive barrier layer 6 made of, for example, tungsten nitride or titanium nitride, and a metal chalcogenide such as molybdenum selenide adjacent to this layer. Ohmic contact layer 8a. In a preferred embodiment, the contact layer 8 a can also be doped with at least one dopant, for example sodium ions or sodium compounds, in particular sodium sulfite or sodium sulfide.

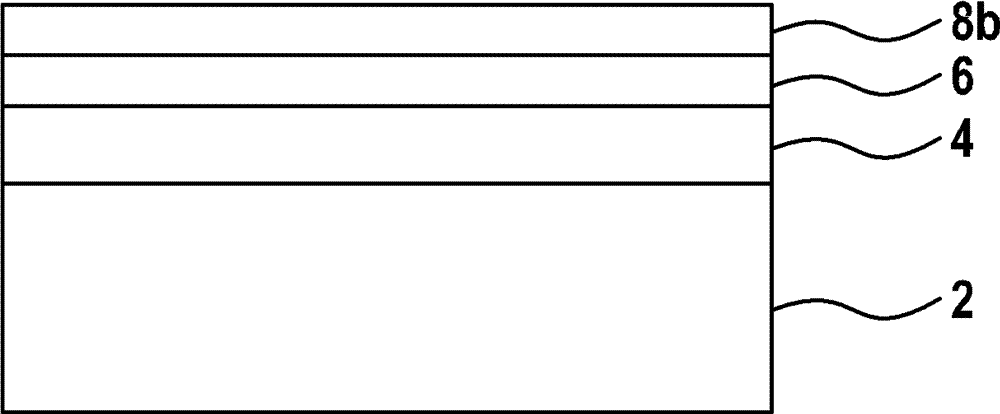

[0049] exist figure 2 In the second embodiment of the multilayer electrode 1 of the invention reproduced in figure 1 In different embodiments, the contact layer 8b is a metal layer, such as a molybdenum layer or a tungsten layer. In a preferred configuration, the contact layer 8 b can also be doped with at least...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com