Method and device for determining internal resistance of battery cells of battery

A battery and battery pack technology that is applied to batteries, measuring devices, secondary batteries, etc., to achieve the effect of avoiding mutual differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

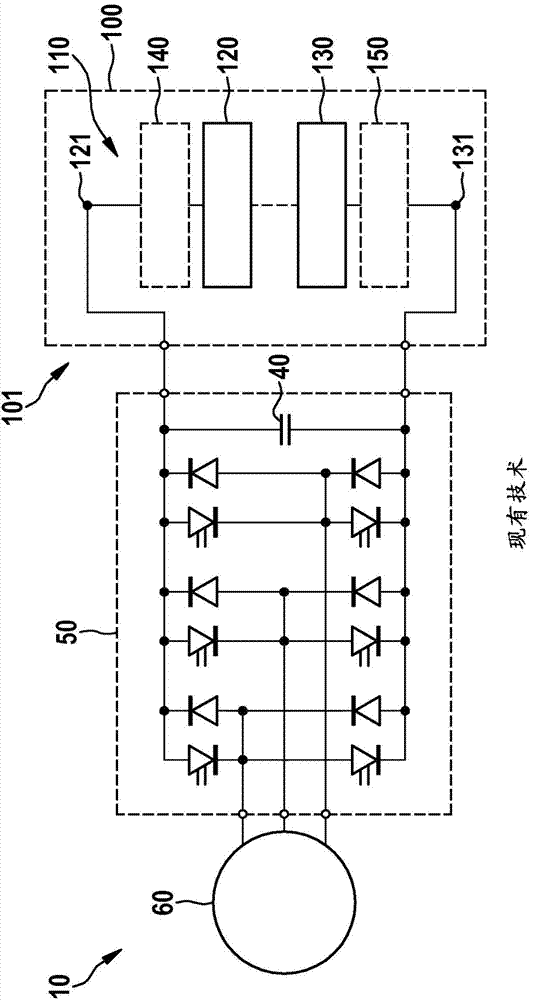

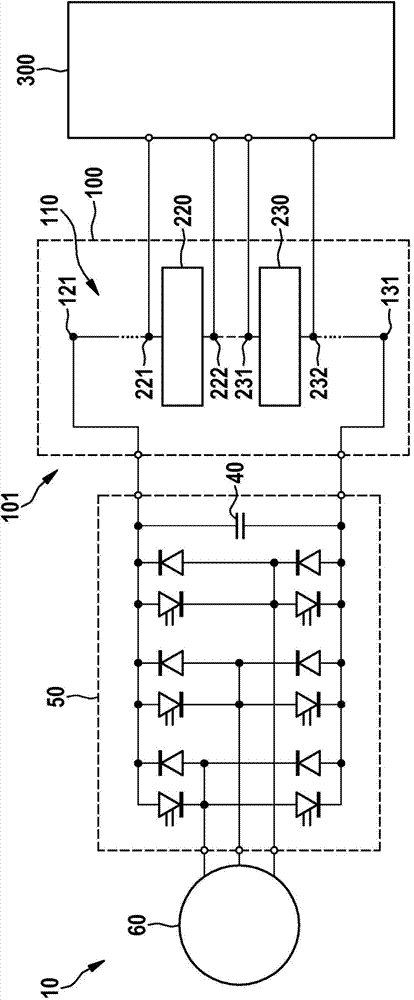

[0035] figure 2 A schematic circuit diagram of a drive system 10 is shown, comprising a battery 100 connected to an electric machine 60 according to the described first embodiment of the invention, which battery is driven by means of a direct battery converter. The battery system 101 comprises a battery 100 which is connected to a DC voltage intermediate circuit (not shown) comprising a capacitor 40 . Also connected to the direct voltage intermediate circuit is the pulse inverter 50 comprised by the battery system 101 , which is connected to the three-phase motor (electric drive motor) 60 at its three outputs via two A controllable semiconductor valve (not shown) and two diodes (not shown) provide multiple sinusoidal voltages which are phase shifted from each other.

[0036] Battery 100 includes a battery pack 110 with a plurality of battery modules connected in series, of which only a first battery module 220 and a second battery module 230 are explicitly shown in the drawi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com