Fireproof bus groove

A busway and fire-resistant technology, applied in the field of power feeding system, can solve the problems of unable to use fasteners, difficult positioning, difficult to fix, etc., to achieve the effect of avoiding external physical deformation, high protection level, and high anti-corrosion requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

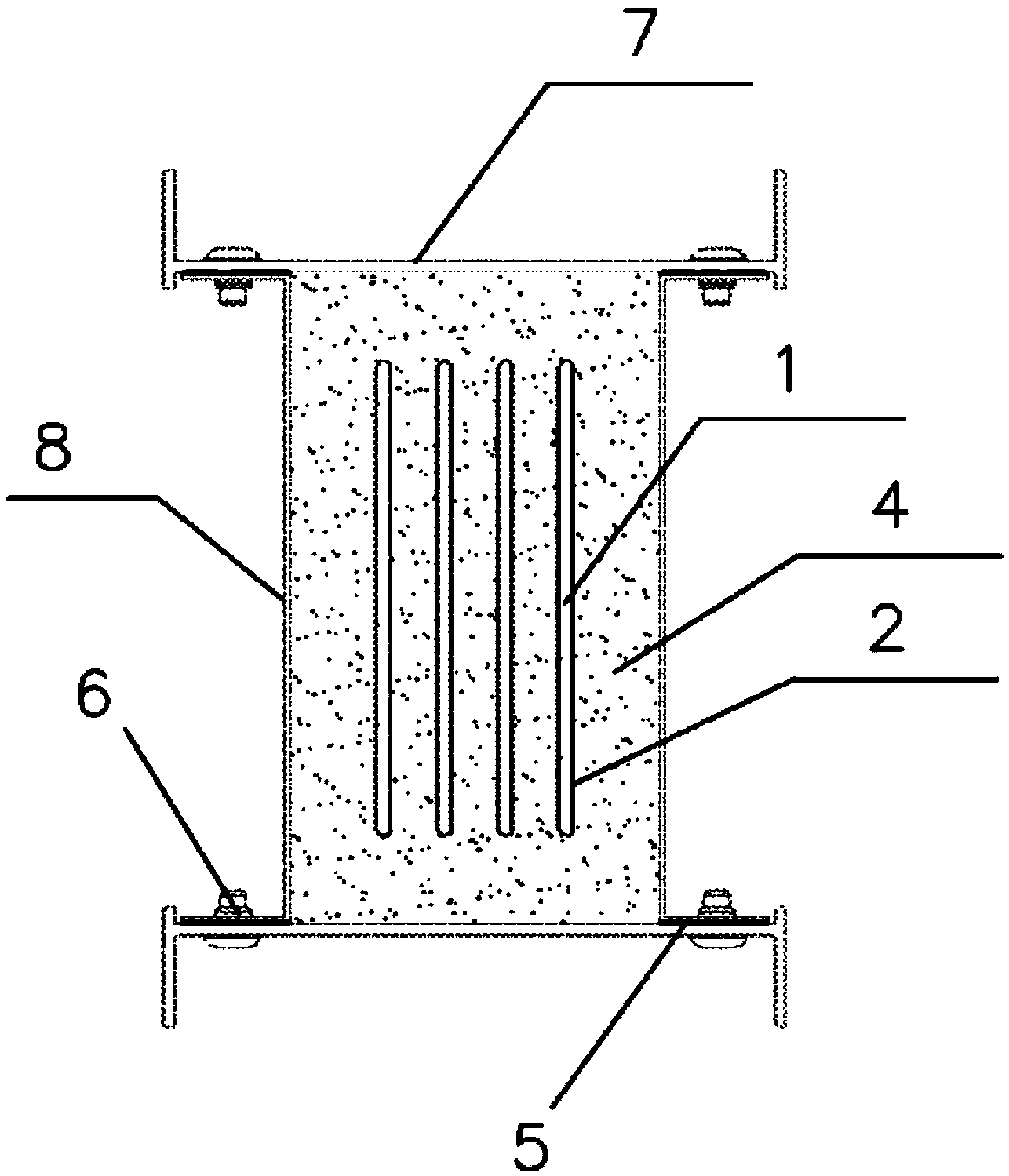

[0010] As shown in the figure, the fireproof busway of the present invention is composed of a shell, a conductor 1, an insulating layer 2, a fireproof filler 4, and a PE conductor 3, and the shell is fixedly connected by a "["-shaped cover plate 7 and a side plate 8 , Conductor 1 is covered with insulating layer 2 and arranged inside the housing. The interval between conductors 1 is filled with refractory filler 4. The refractory filler 4 is mineral material. The insulating layer 2 is made of gold belt. The connection part of the housing is Interlayers 5 are provided and fastened by fasteners 6 to prevent the refractory filler 4 from overflowing after the fireproof busbar shell is shaken and loosened. The PE conductor 3 is arranged inside the shell close to the edge of the side plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com