Clamping mechanism of testing device for direct tensile strength of fragile material

A technology of tensile strength and testing equipment, applied in measuring equipment, using stable tension/compression to test material strength, analyzing materials, etc., can solve problems such as specimen damage, achieve improved clamping, and avoid bending and twisting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

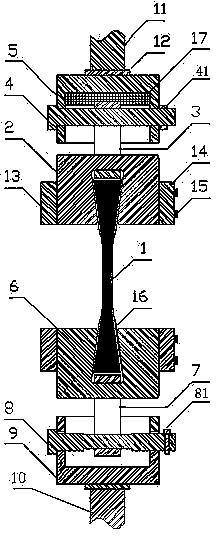

[0021] Such as figure 1 As shown, the present invention includes an upper clamping part and a lower clamping part, and the upper clamping part includes an upper wedge clamp 2, an upper ring 3, an upper cylindrical pin 4 and an upper cylinder 5, and the upper wedge clamp 2 passes through the upper circle The ring 3 is suspended on the upper cylindrical pin 4 of the upper cylinder 5, and the upper cylindrical pin 4 is installed on the pin hole of the upper cylinder 5, and the upper cylinder 5 and the upper pull rod 11 of the testing machine are connected by threads; The components include a lower wedge clamp 6, a lower ring 7, a lower cylindrical pin 8 and a lower cylinder 9. The lower wedge clamp 6 is connected to the lower cylindrical pin 8 of the lower cylinder 9 through the lower ring 7, and the lower cylindrical pin 8 is installed on the lower cylinder. O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com