High temperature prevention infrared temperature measurement equipment

An infrared temperature measurement and anti-high temperature technology, which is applied in the field of infrared thermometers, can solve the problems of short detection range, unsteady hands when the hands are heated, and achieve the effect of preventing human hands from being heated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

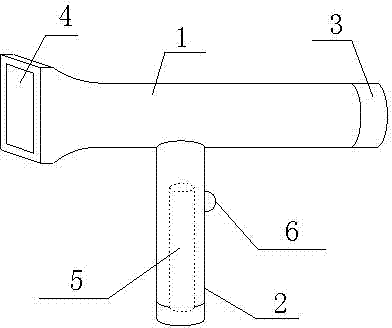

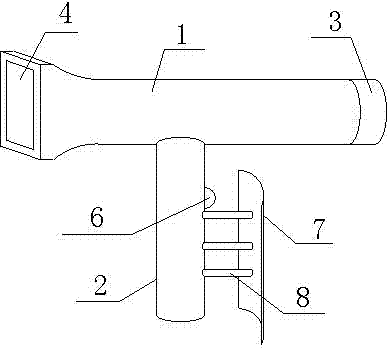

[0017] Such as figure 2 As shown, the anti-high temperature infrared temperature measuring equipment includes a body 1 and a handle 2 vertically installed under the body 1. The handle 2 is provided with a hand guard 7, and the hand guard 7 is arranged on the handle 2 close to the infrared On the end face of the sensor 3, the hand guard 7 is connected to the handle 2 through three connecting rods 8, and the connecting rods 8 are arranged at intervals along the extending direction of the handle 2, and the distance between adjacent connecting rods 8 is 2-3 cm. In this device, a hand guard 7 is set on the side of the handle 2 facing the infrared sensor, and the infrared sensor 3 is to face the fire source, so the hand guard 7 is arranged on the side of the handle 2 facing the fire source, and the hand guard 7 passes through Three connecting rods 8 are connected to the handle 2. When using the thermometer, the staff holds the handle 2 with their hands, and the three connecting rod...

Embodiment 2

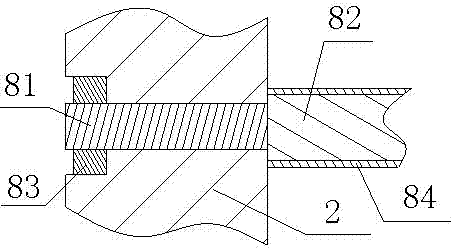

[0019] Such as image 3 , the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the connecting rod 8 and the handle 2 are flexibly connected, the connecting rod 8 includes a mounting part 81 and a connecting part 82, and the diameter of the connecting part 82 is larger than that of the mounting part 81, the installation part 81 runs through the handle 2, and is exposed at the other end of the handle 2, and the exposed part of the installation part 81 is provided with an external thread, and the handle 2 is clamped by the nut 83 and the connecting part 82, so that the connecting rod 8 and the handle 2 Fixation in the direction of extension. This installation method can make the hand guard block 7 detachable. After using the thermometer, the nut 83 is unscrewed, the connecting rod 8 is extracted from the handle 2, and the hand guard block 7 is removed, which avoids the During the transportation process, due to collision with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com