A long-stroke pumping unit

An oil pumping unit and frame technology, which is applied in the field of oil pumping equipment, can solve the problems of high requirements on connecting rod materials and manufacturing precision, difficulty in manufacturing and operation management, difficulty in manufacturing and installation, etc. The stroke adjustment is convenient and the effect of eliminating the impact load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

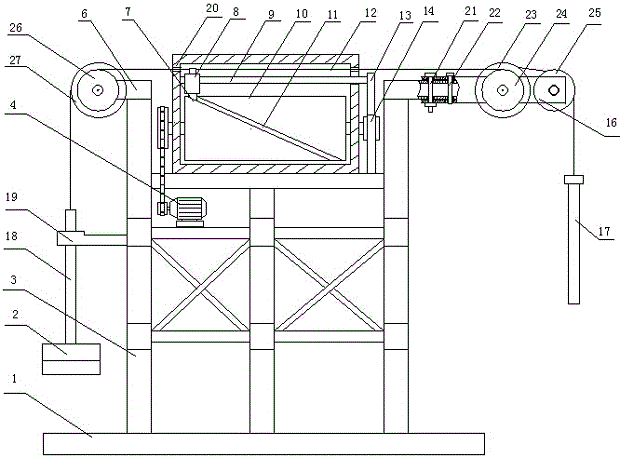

[0026] Such as figure 1 , figure 2 Shown: the long-stroke pumping unit of the present invention includes a base 1, a frame 3, a drive motor 4, a reversing transmission mechanism, a balance mechanism and a load mechanism. The reversing transmission mechanism is located on the upper part of the frame 3, connected with the frame 3 through the shaft seat 14, and connected with the balance mechanism and the load mechanism through the traction steel rope 12 respectively. The driving motor 4 is connected with the reversing transmission mechanism through a transmission member. The reversing transmission mechanism includes a reversing roller 10, a sliding mechanism and a sliding guide rod 9. The cross section of the sliding guide rod 9 is a rectangular structure to prevent the sliding mechanism from rotating. The sliding mechanism includes a sliding seat 8 and a sliding block 7 connected thereto, and the sliding block 7 and the sliding seat 8 may adopt an integral structure. Front ...

Embodiment 2

[0029] Such as image 3 , Figure 4Shown: the long-stroke pumping unit of this embodiment includes a base 1, a frame 3, a drive motor 4, a reversing transmission mechanism, a balance mechanism and a load mechanism. The reversing transmission mechanism is located on the upper part of the frame 3, connected with the frame 3 through the shaft seat 14, and connected with the balance mechanism and the load mechanism through the traction steel rope 12 respectively. The driving motor is connected with the reversing transmission mechanism through the transmission member. The reversing transmission mechanism includes a reversing roller 10, a sliding mechanism and a sliding guide rod 9, and the sliding guide rod 9 can be set as two round rods to effectively prevent the sliding mechanism from rotating and reduce the size of the guide rod. 9 Friction with the sliding mechanism. The sliding mechanism includes a sliding seat 8 and a sliding block 7 movably connected with it, the sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com