An electrolytic plate with embossed leveling and enhanced rigidity and its preparation method

A technology of embossing and plate, which is applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of increasing cathode and anode short circuit on site, secondary stress deformation of plate, and inability to completely solve the plate, so as to reduce manual work Strength, eliminate internal stress, and reduce the effect of short circuit phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

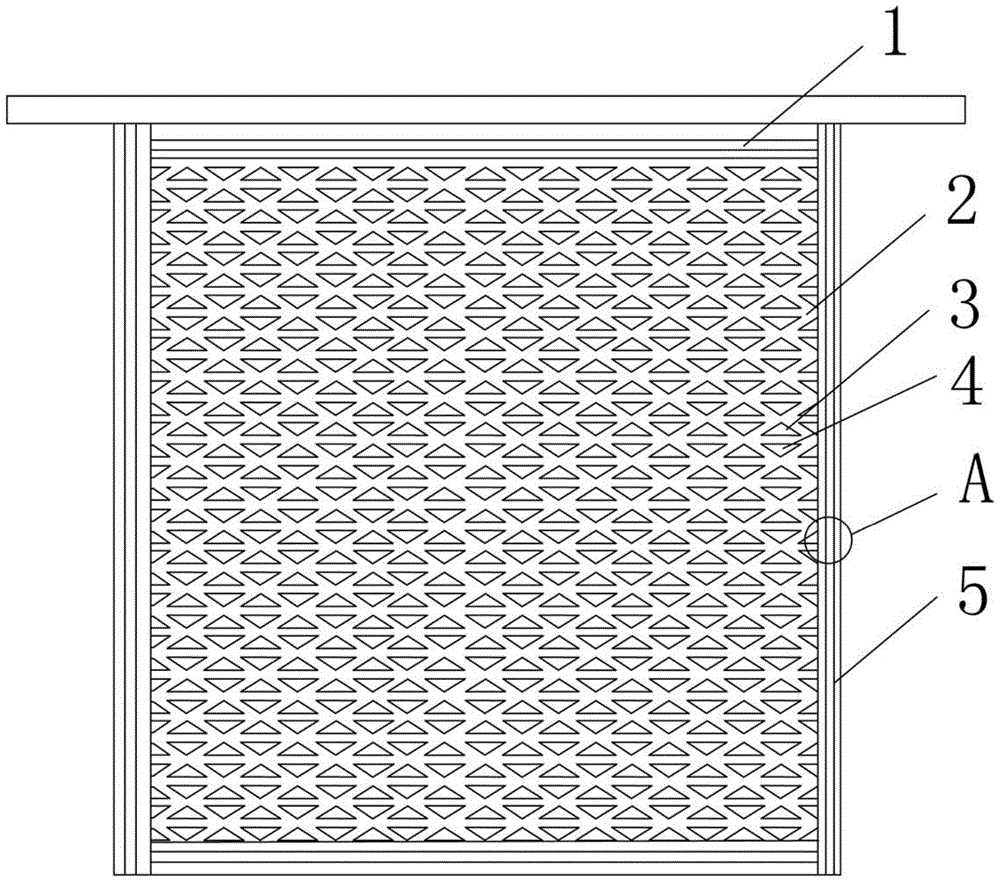

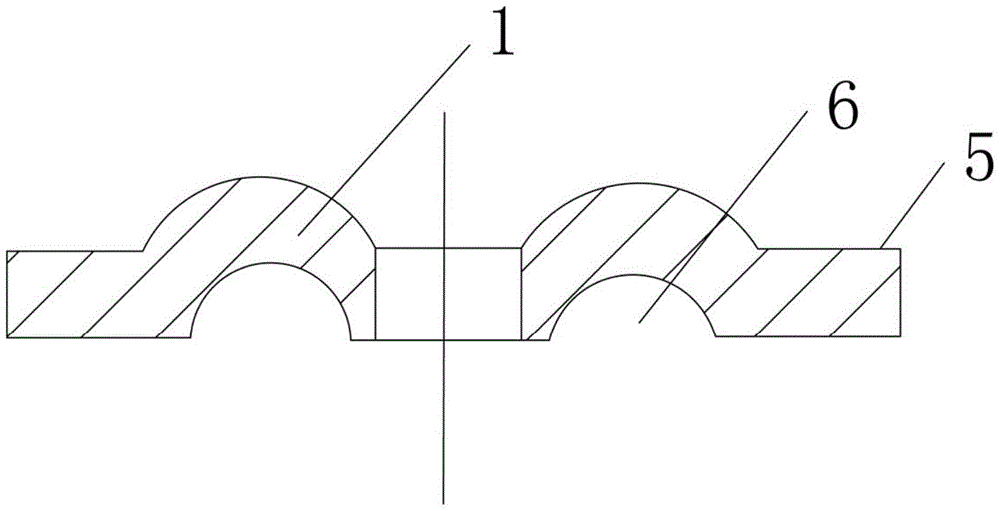

[0023] Embodiment 1: The method for improving the flatness of the plate surface of the reticulated titanium-plated lead dioxide anode: this embossed and leveled electrolytic plate that enhances rigidity mainly includes a pole plate 1, and the surface of the pole plate 1 is provided with Several embossing grooves 2 form a concave-convex pattern. The insoluble anode plate is made of a titanium mesh plate, the thickness of which is 1mm to 3mm. First, the mesh plate is cut according to a certain size, and then the stripes are pressed by a flat press. The embossing groove 2 is composed of a plurality of horizontal The embossed grooves and oblique embossed grooves form a Pozi-shaped structure, and a protruding structure consisting of upper triangular bumps 3 and lower triangular bumps 4 is formed on the pole plate 1 . The depth of the pressed stripes is 2.5mm, and the stripes on the entire board surface are continuous stripes. After pressing, the surface of the board is flat, and t...

Embodiment 2

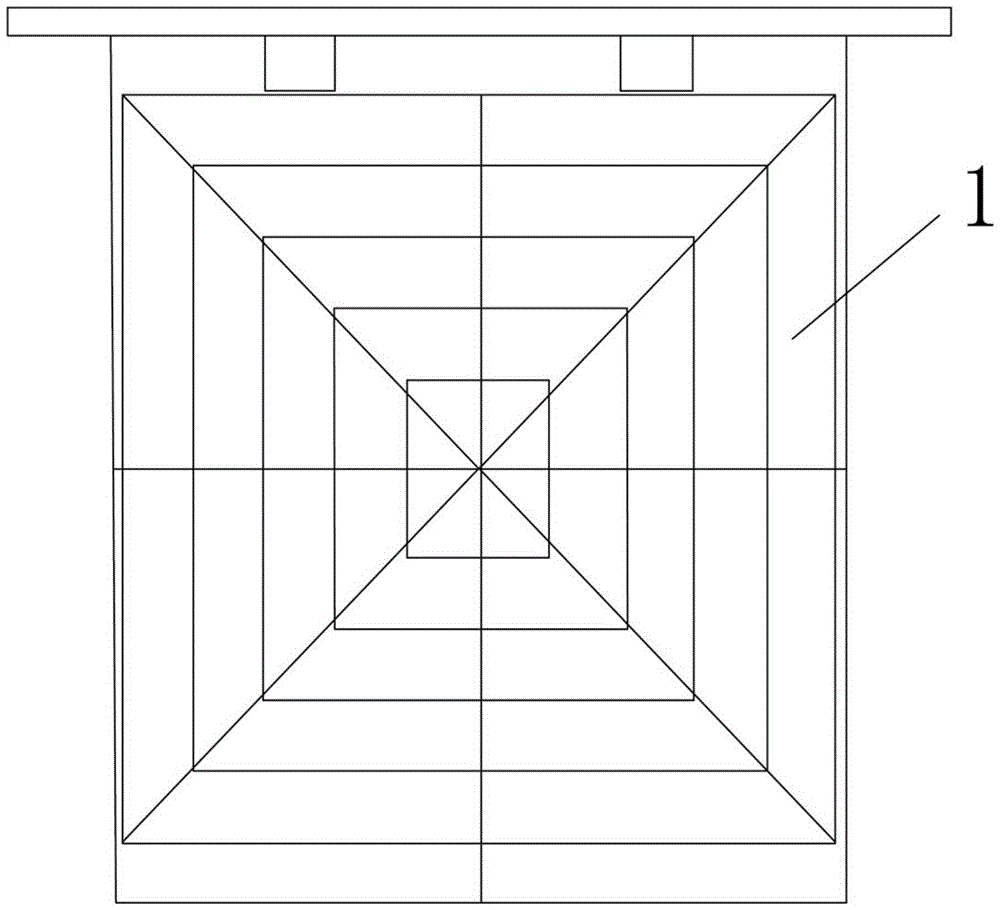

[0024] Embodiment 2: The method for improving the flatness of titanium-coated noble metal oxide anode plate surface: adopt titanium plate to make insoluble anode plate, its plate thickness is 1mm to 3mm, first cut plate according to a certain size, and then use flat embossing machine Stripes are pressed, and the stripes are in the shape of "back" or "field" (such as Figure 5 ), etc., the depth of the pressing stripes is 2.5mm, and the stripes on the entire board surface are continuous stripes. After pressing, the surface of the board is flat, and the rigidity is significantly enhanced.

Embodiment 3

[0025] Embodiment 3: as Figure 4 , The method of improving the flatness of the lead alloy anode plate surface: use the lead alloy plate to make the insoluble anode plate, and the thickness of the plate is 3mm to 10mm. Firstly, the lead alloy plate is cast according to a certain size, and then the flat embossing machine is used for stripe pressing. The shape of the stripes is radial, etc., the depth of the pressed stripes is 2.5 mm, and the stripes on the entire board surface are continuous stripes. In this way, the surface strength of the produced lead alloy anode plate is significantly enhanced, and the flatness of the plate surface is greatly improved.

[0026] The present invention adopts stripe pressing on the polar plate to increase the flexural section modulus of the polar plate, eliminate part of the stress, and achieve the purpose of enhancing the rigidity of the polar plate. It not only enhances the rigidity of the plate, increases the vertical flatness of the plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com