Granular Cotton Cotton Making System Using Hot Slag

A hot slag, cotton-to-cotton technology, applied in the direction of manufacturing tools, glass manufacturing equipment, etc., to achieve the effect of promoting formation, improving fiber formation rate and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

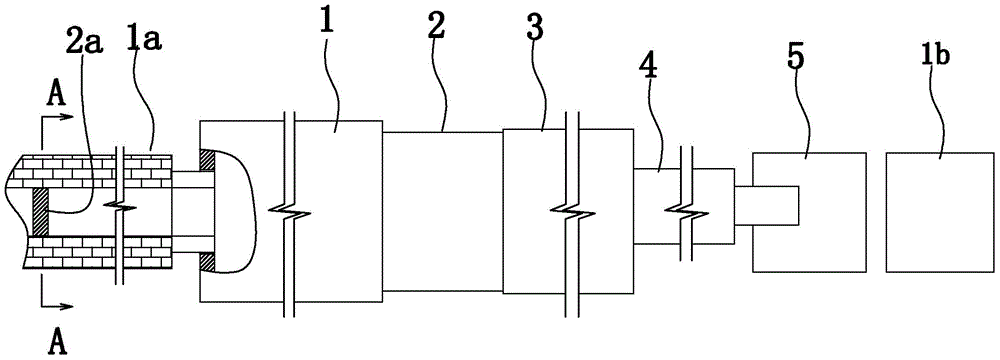

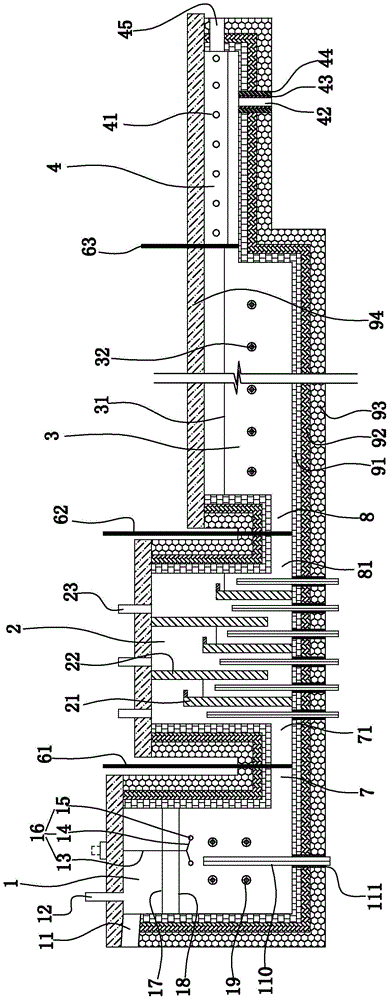

[0056] Embodiment 1: as figure 1 As shown, a granular cotton cotton making system utilizing hot slag includes a slag ditch 1a for diverting hot slag from a blast furnace, a slag furnace, a four-roller centrifuge 5, a cotton collector and a granulator; Cotton collector and granulator among the present embodiment are prior art.

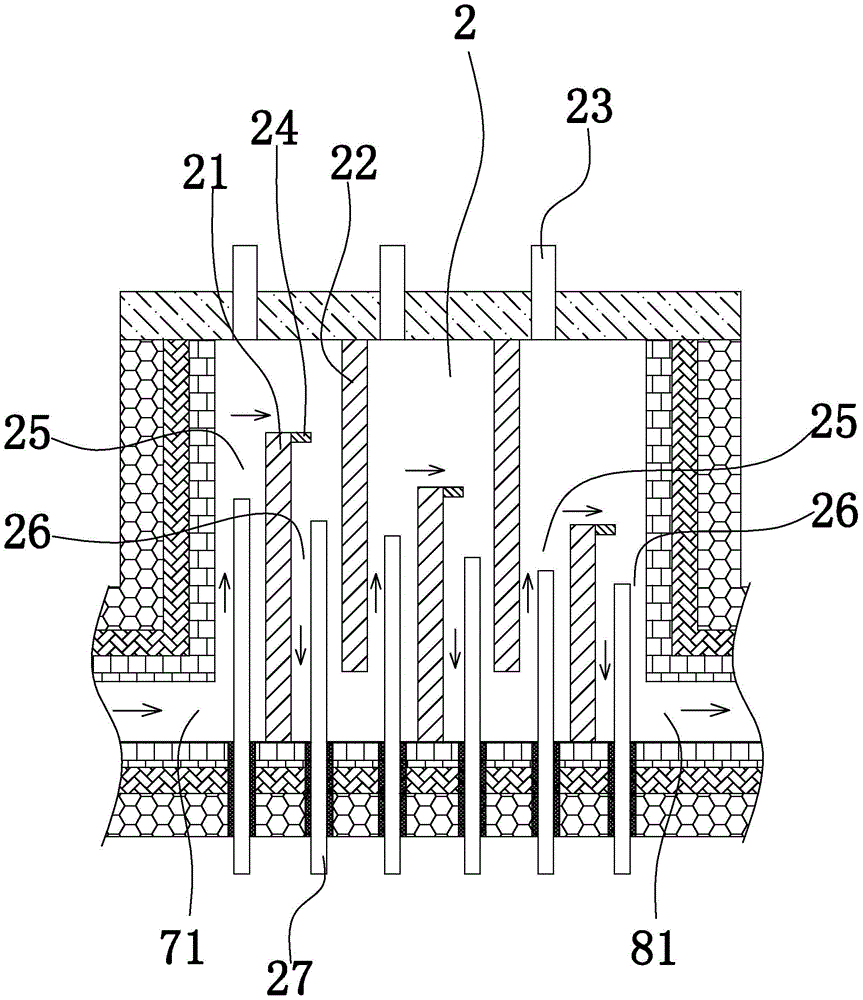

[0057] Such as figure 1, As shown in 2, the slag furnace includes a feeding pool 1, a homogenizing pool 2, a melting pool 3 and a forehearth 4 in sequence. The bottom of the feeding tank and the bottom of the homogenizing tank are connected through a first flow channel 7 . The bottom of the homogenizing tank and the bottom of the melting tank are connected through the second flow channel 8 . One end of the forehearth communicates with the melting pool, and the other end is closed. The lower part of the material channel is provided with a material outlet. The bottom of the feeding tank is provided with a liquid outlet of the feeding tank. The botto...

Embodiment 2

[0086] Embodiment 2: all the other structures in this embodiment are with reference to embodiment 1, and its difference is:

[0087] Such as figure 1 , Figure 10 As shown, the cotton collector 1b includes a cotton collector shell, a cotton mesh belt device, a cotton inlet air port 5b and a negative pressure air port 15b on the cotton collector shell, a cotton conveyor belt 8b positioned outside the cotton collector shell and Scraper 7b. The cotton outlet air outlet of the centrifuge is set opposite to the cotton inlet air outlet of the cotton collector, and the distance between the cotton outlet air outlet and the cotton inlet air outlet is between 1 and 1.5 meters. An exhaust fan is provided at the negative pressure air outlet of the cotton collector.

[0088] A cotton collecting chamber 2b, an air-drying chamber 3b and a cleaning chamber 4b are sequentially arranged in the cotton collecting machine shell. The cotton-collecting mesh belt device includes four sprockets an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com