High-efficiency energy-saving stirring aerator for cable production sewage treatment

A high-efficiency and energy-saving technology for sewage production, applied in water/sludge/sewage treatment, water aeration, sustainable biological treatment, etc., can solve the problems of low dissolved air efficiency and achieve the effect of improving the effect and improving the dissolved air efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

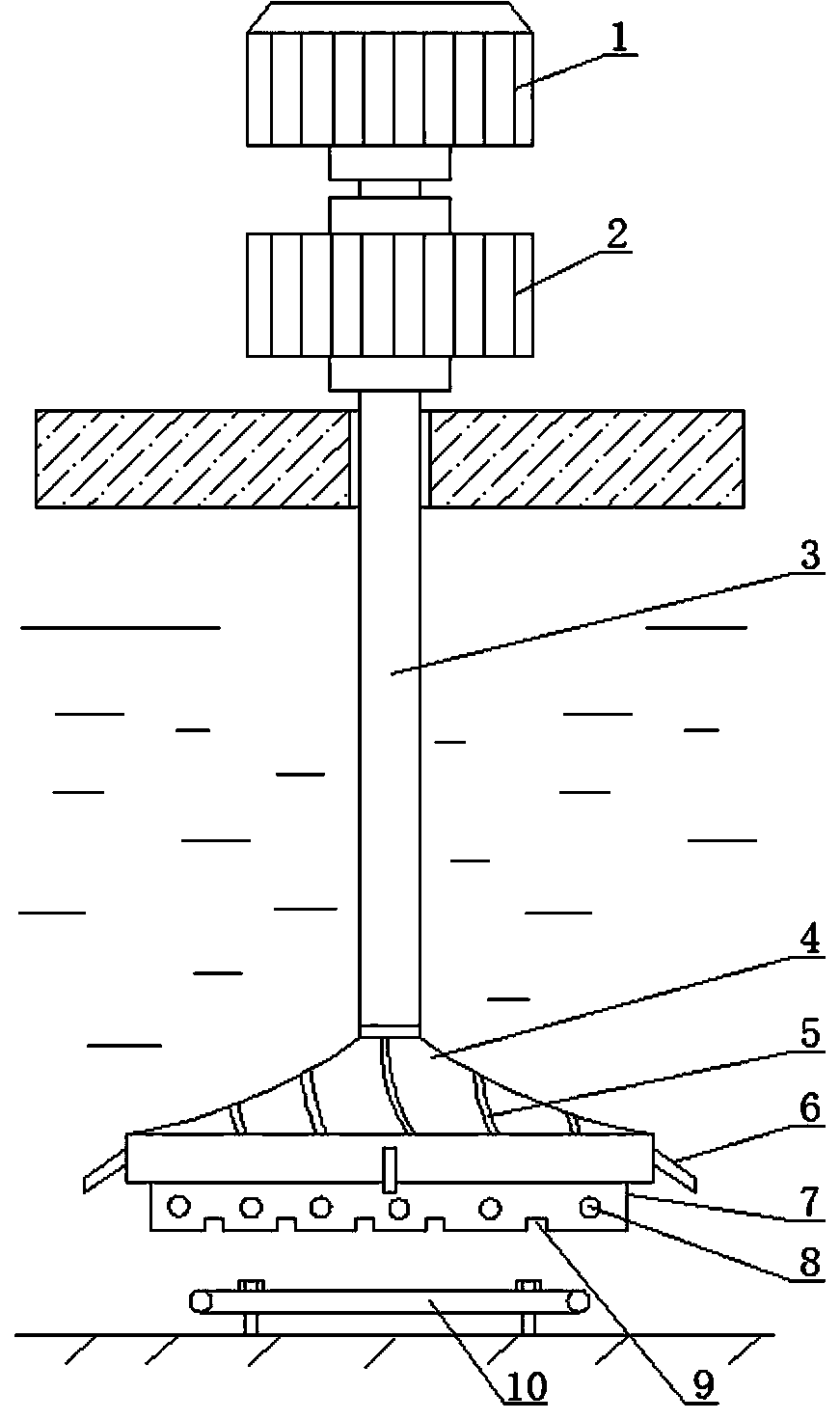

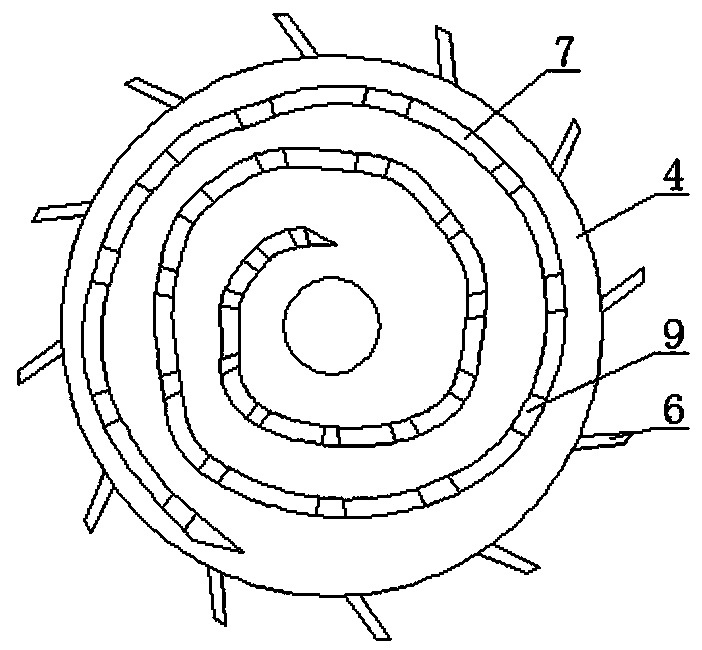

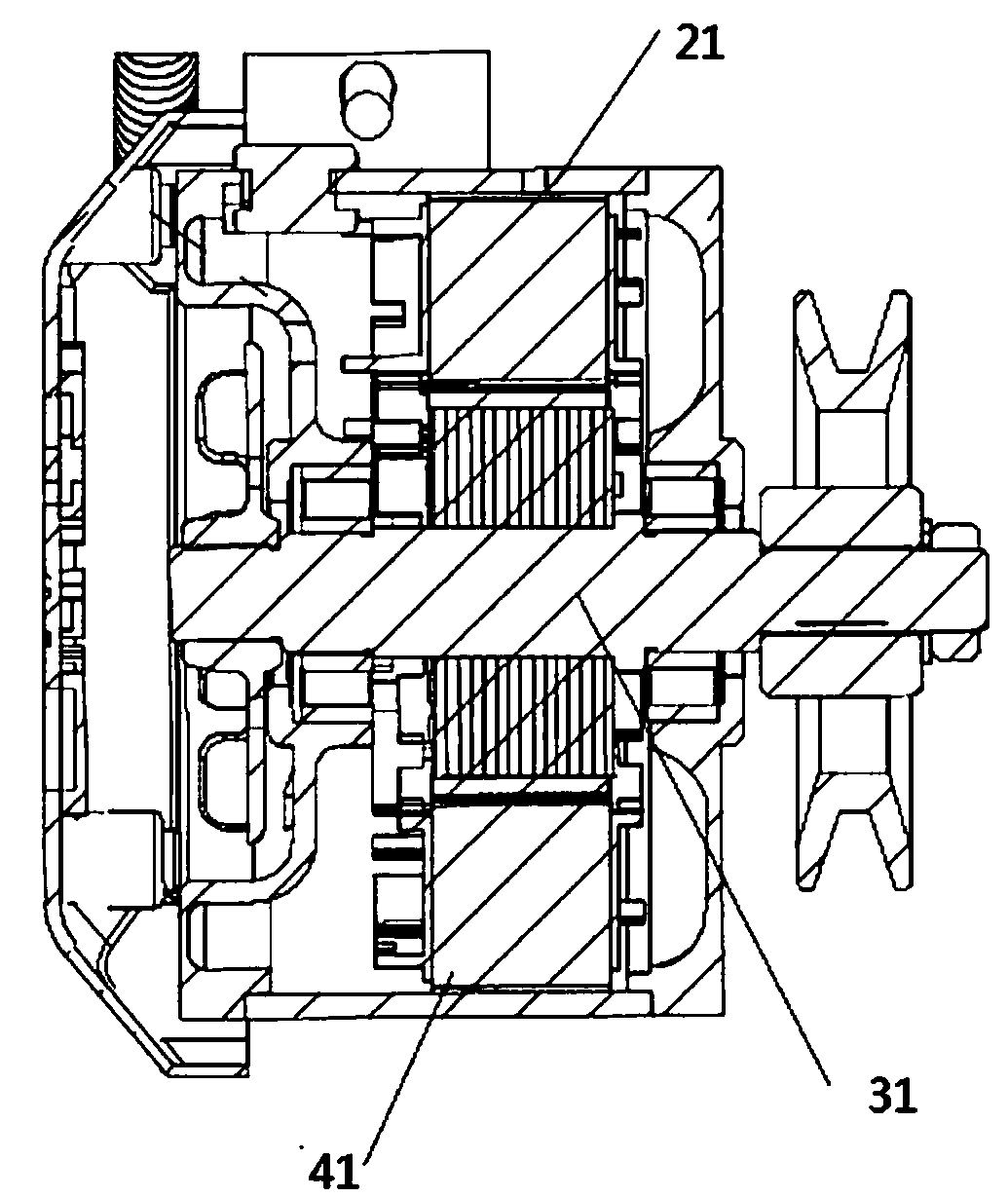

[0036] The high-efficiency energy-saving agitating aerator for cable production sewage treatment of the present invention includes a drive motor, the drive motor includes a casing, a stator assembly and a rotor assembly, the rotor assembly includes a motor shaft, and the motor shaft is connected to Rotating shaft, the lower end of the rotating shaft is connected with a dispersing disc, and the lower part of the dispersing disc is equipped with an air distribution pipe. The lower surface of the spiral blade is provided with a helical blade, and a plurality of diversion holes are opened on the lower bottom surface of the helical blade; the helical blade is provided with through holes.

Embodiment 2

[0038] The high-efficiency energy-saving agitating aerator for cable production sewage treatment of the present invention includes a drive motor, the drive motor includes a casing, a stator assembly and a rotor assembly, the rotor assembly includes a motor shaft, and the motor shaft is connected to Rotating shaft, the lower end of the rotating shaft is connected with a dispersing disc, and the lower part of the dispersing disc is equipped with an air distribution pipe. The lower surface of the spiral blade is provided with a spiral blade, and the lower bottom surface of the spiral blade is provided with a plurality of diversion holes; the spiral blade is provided with a through hole; the outer peripheral surface of the dispersion plate is evenly provided with a plurality of stirring plates.

Embodiment 3

[0040] The high-efficiency energy-saving agitating aerator for cable production sewage treatment of the present invention includes a drive motor, the drive motor includes a casing, a stator assembly and a rotor assembly, the rotor assembly includes a motor shaft, and the motor shaft is connected to Rotating shaft, the lower end of the rotating shaft is connected with a dispersing disc, and the lower part of the dispersing disc is equipped with an air distribution pipe. The lower surface of the spiral blade is provided with a spiral blade, and the lower bottom surface of the spiral blade is provided with a number of diversion holes; the spiral blade is provided with a through hole; the outer circumferential surface of the dispersion plate is evenly provided with a plurality of stirring blades; The stirring plate is obliquely connected to the outer surface of the dispersing disc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com