An automatic reset wire rope brake

An automatic reset and wire rope technology, which is applied in the field of automatic reset wire rope brakes and elevator safety brake devices, can solve the problems of large backup power capacity, limited operating space, and large electromagnet current, etc., to achieve perfect functions, better performance, The effect of performance optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

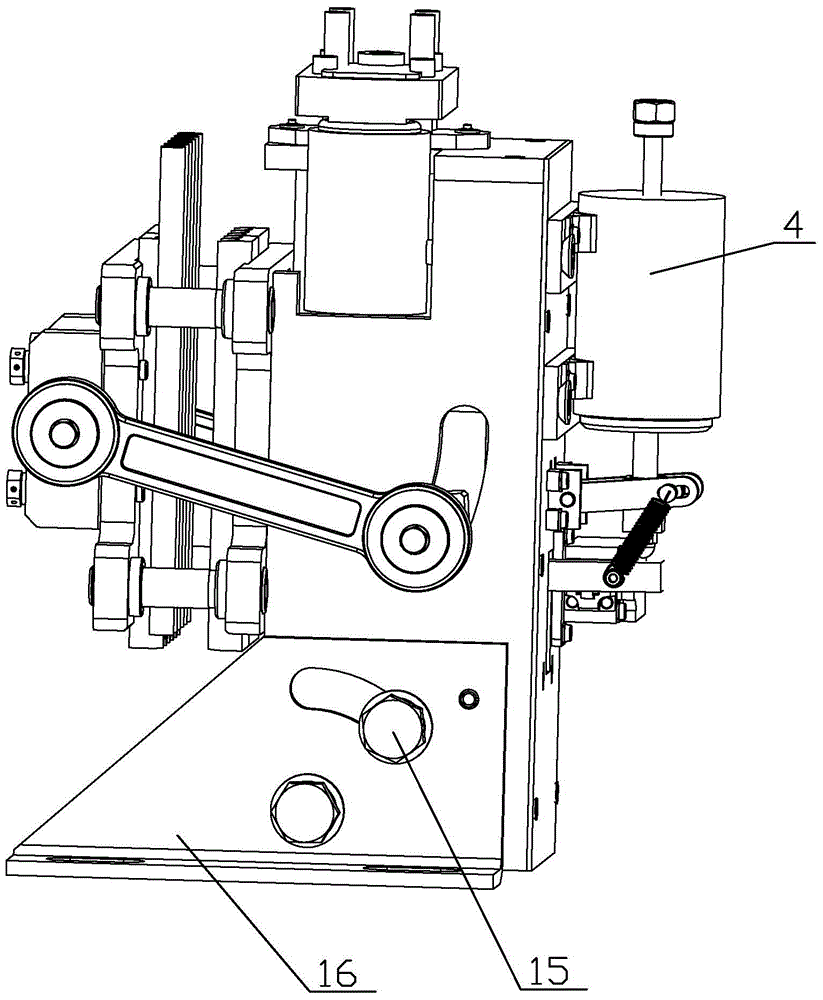

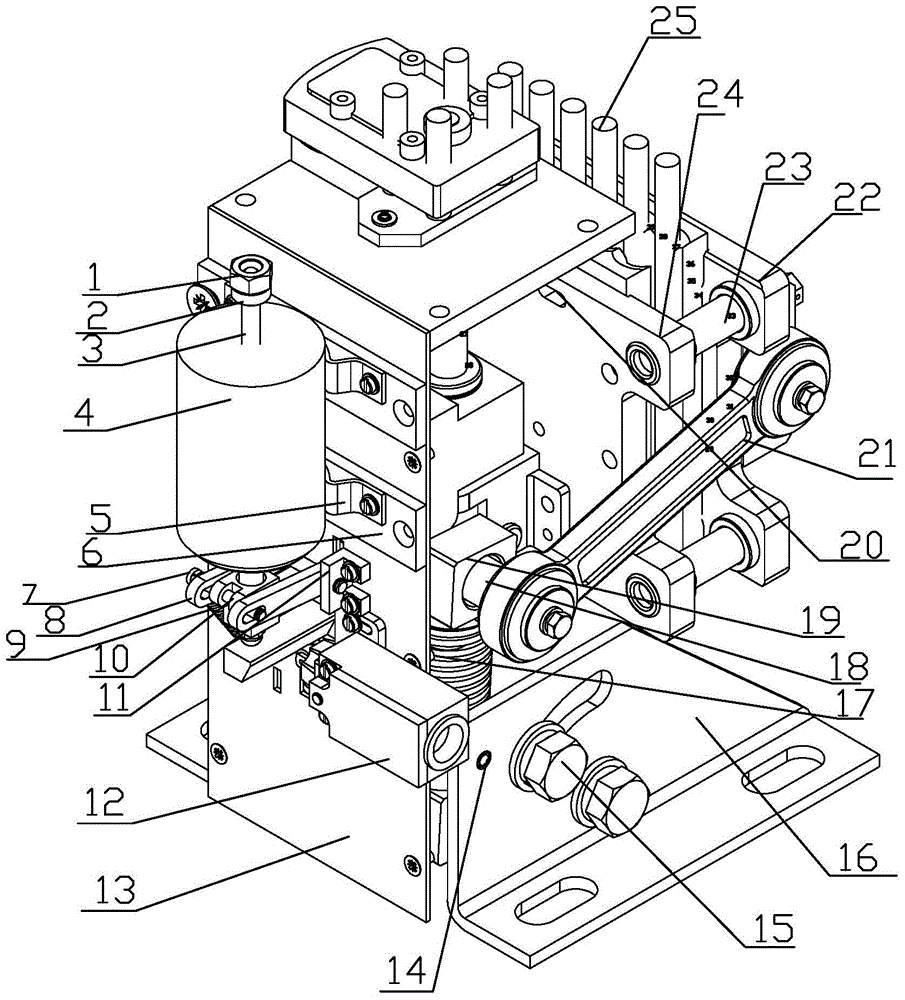

[0042] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0043] Such as Figure 1-11 As shown, this embodiment includes a motor screw push block reset mechanism, an electromagnet reset mechanism, a frictional / fixed brake liner mechanism, an electromagnetic trigger mechanism, etc., and its connection relationship is: the motor screw push block reset mechanism is installed on the upper top plate Between the lock hook frame, the electromagnet reset mechanism is connected with the motor screw push block reset mechanism, the friction braking brake / custom brake liner is installed on the dynamic / custom brake plate, and the electromagnetic trigger mechanism is installed on the rear side plate. The structure is described below:

[0044] The top plate 41 is installed on the upper part of the wire rope brake, and the two side plates 26 are respectively installed on the installation plates 16 on both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com