A heavy equipment transfer system with curved track transportation

A heavy-duty equipment, curved track technology, used in transportation and packaging, conveyors, mechanical conveyors, etc., to meet transshipment requirements, reduce quantity and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

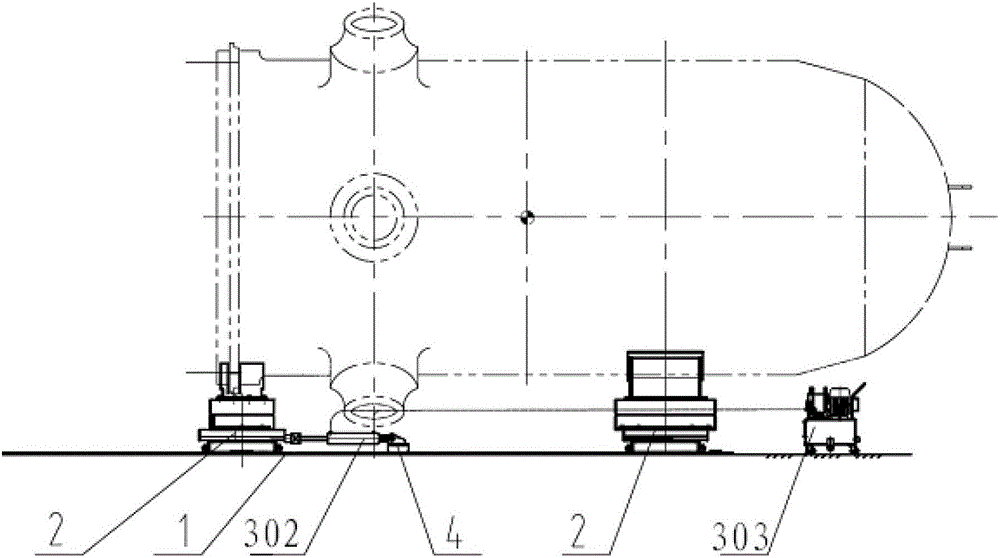

[0024] The present invention is a heavy equipment transfer system with curved track transportation, including heavy rail 1, heavy truck 2, and power unit 3;

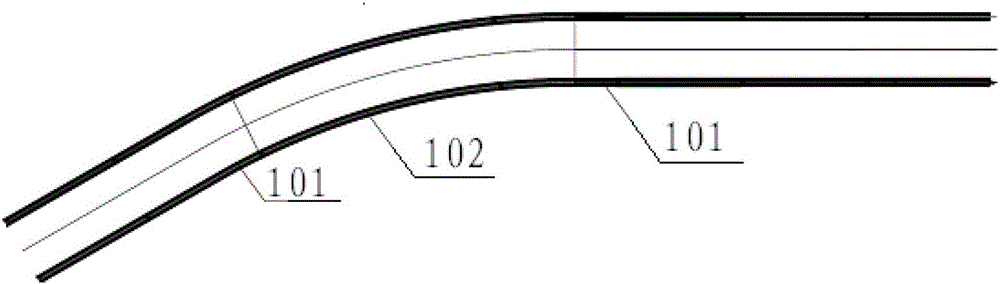

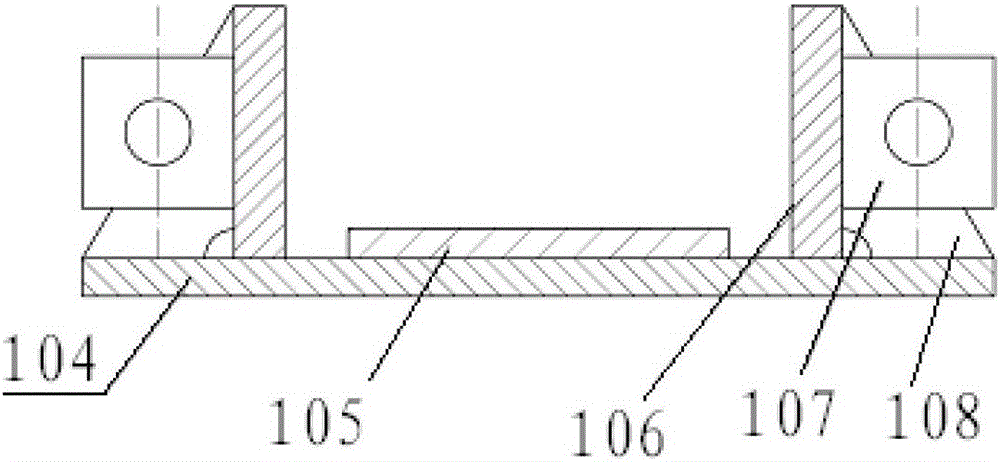

[0025] Heavy rail 1 comprises two rails side by side, and described two rails all comprise straight section 101 and curved section 102; Every root track comprises track base plate 104, track plate 105, two track sidewalls 106 along base plate extending direction; The track is connected by several track segments;

[0026] Each track section is a "groove" structure;

[0027] The track base plate 104 is placed on the ground, and the track plate 105 extends along the track base plate 104 and is welded on the upper surface of the track base plate 104; the two track side walls 106 of each track are fixed on both sides of the upper surface of the track base plate 104 and extend along the track base plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com