A horizontal paper feeding device

A horizontal and pressing device technology, applied in the direction of mechanical processing/deformation, can solve the problems of affecting production efficiency, prolonging the paper feeding time, and large deformation, so as to save paper loading time, improve processing efficiency, and smooth and smooth conveying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with accompanying drawing:

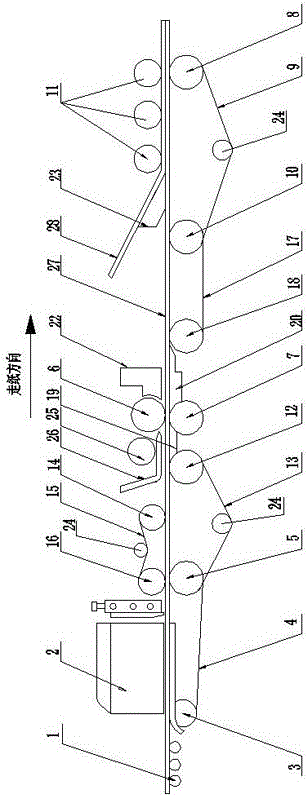

[0019] see figure 1 , An embodiment of a transverse paper feeding device of the present invention, including: a bracket roller 1, a bottom paper side stop device 2, a paper feeding device, a glue roller 6, a water roller 7, and a pressing device.

[0020] Above-mentioned base paper side blocking device comprises guide shaft 2-1, the positioning baffle plate between the guide shaft 2-1 middle part, the side clap baffle plate 2-3, the baffle plate mobile hand wheel at the two ends of guide shaft 2-1, the side clap mobile handwheel. Rounds 2-4. The paper feeding device includes a suction paper feeding device composed of a paper feeding driven roller 3 , a paper feeding suction belt 4 and a paper feeding driving roller 5 . The pressing device includes a pressing driving roller 8 , a pressing suction belt 9 , a pressing driven roller 10 and several upper pressing rollers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com