3D (three dimensional) printing process with laser beam scanning in archimedes spiral way

An Archimedes spiral, 3D printing technology, applied in the field of 3D printing technology, can solve the problems of affecting the scanning effect, reducing the deflection angle, application difficulties, etc., to improve the printing quality, reduce the relative size and reduce the cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: the whole machine adopts the present invention that 3 lasers are mounted on the laser disc of the turntable;

Embodiment 2

[0022] Embodiment 2: The whole machine adopts the present invention in which three lasers are mounted on the turntable guide rail guide frame;

Embodiment 3

[0023] Embodiment 3: The whole machine adopts the present invention that a single laser is set independently from the turntable;

[0024] Example 1:

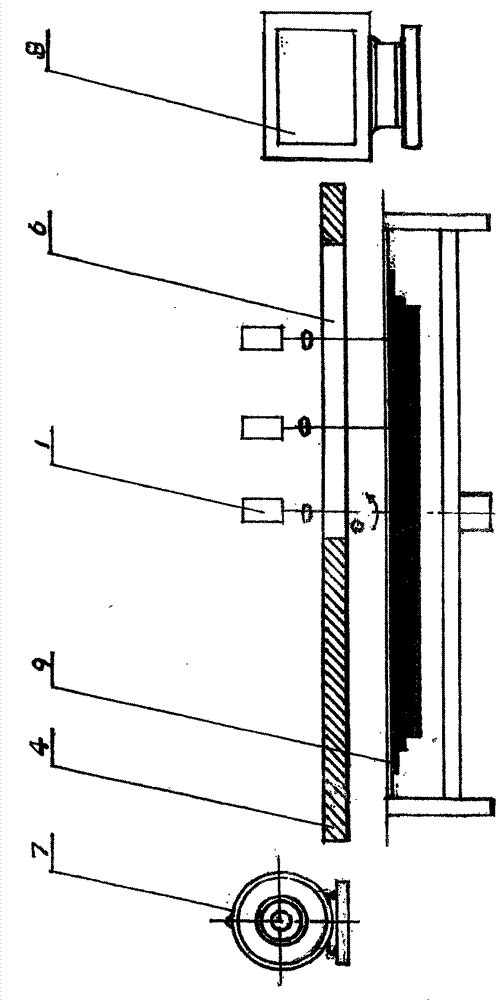

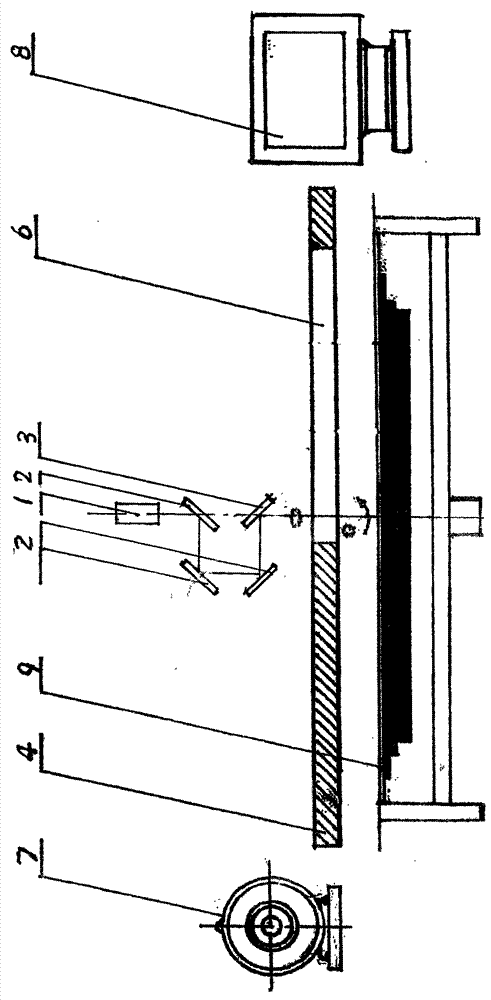

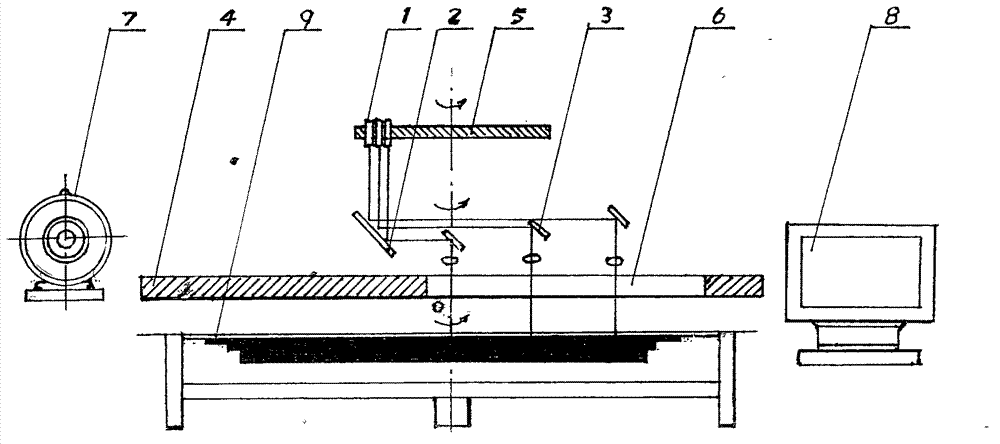

[0025] The whole machine adopts the Archimedes line scanning 3D printing process ( figure 1), including: laser (1) and optical path system (2, 3), turntable (4) and guide rail (11) guide frame (13) system, spindle motor (7) and guide frame translational servo motor (10, 12) system , computer (8) control system. Said laser (1) and optical path system (2, 3) are characterized in that three lasers (1) are arranged in a straight line and eccentrically installed on the laser disk (5) of the turntable (4), and the laser beam (1) is then Eccentrically introduced into the optical path system (2, 3) on the turntable (4), the laser beam is reflected by the fixed mirror (2) on the turntable (4), and enters the translational guide frame (13) on the guide rail (1) in sequence The three reflectors (3) of each reflector (3) are reflected an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com