Wide-range titanium plate flaying polishing machine

A polishing machine, titanium plate technology, applied in the direction of grinding/polishing equipment, grinding/polishing safety devices, grinding machine parts, etc., can solve problems such as uneven thickness, large dust, grinding wheel flying out, etc., to achieve safety Improved performance and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

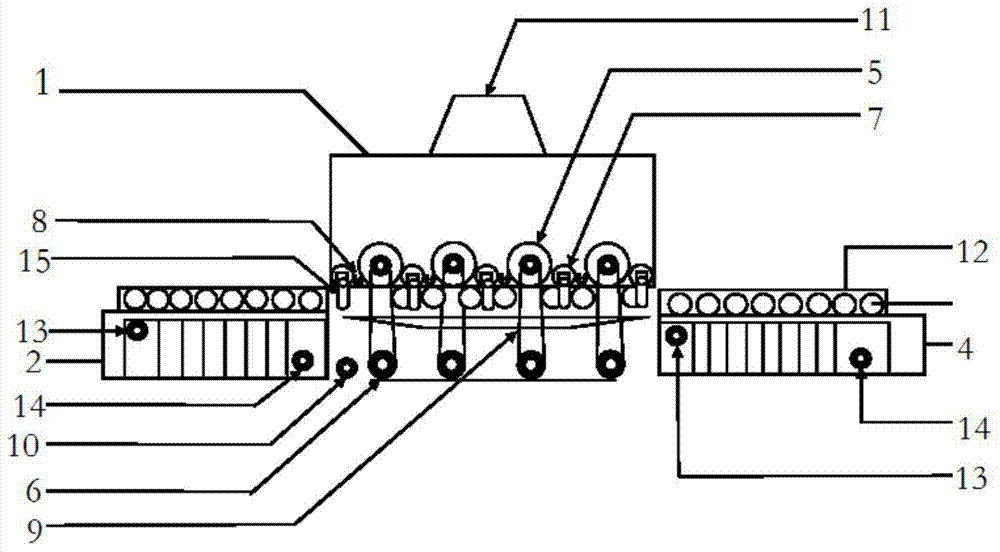

[0018] Such as figure 1 , using the feeding platform drive system 13 to send the titanium stripped and polished metal plate into the grinding platform, and through 4 groups of grinding rollers 5 with different thicknesses and grain sizes to be synchronously polished to complete the stripping and polishing process on the surface of the plate. The grinding thickness can be set through mechanical adjustment in advance, so as to achieve a more ideal plate processing quality. Set 4 sets of grinding rollers 5 on the grinding platform, and set 1 set of 5 pressure calibration rollers at the same time, which are evenly arranged among the grinding rollers 5, and at the same time force the leveling of the flatness of the plate to ensure the unifo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com