Electric-energy-saving slicing cooling water circulation system

A technology that saves electric energy and circulates the system. It is applied in the field of solar photovoltaics, which can solve the problems of increasing enterprise costs, large power consumption, and wasting electric energy. It achieves the effects of low power consumption, low cost, and precise water temperature control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

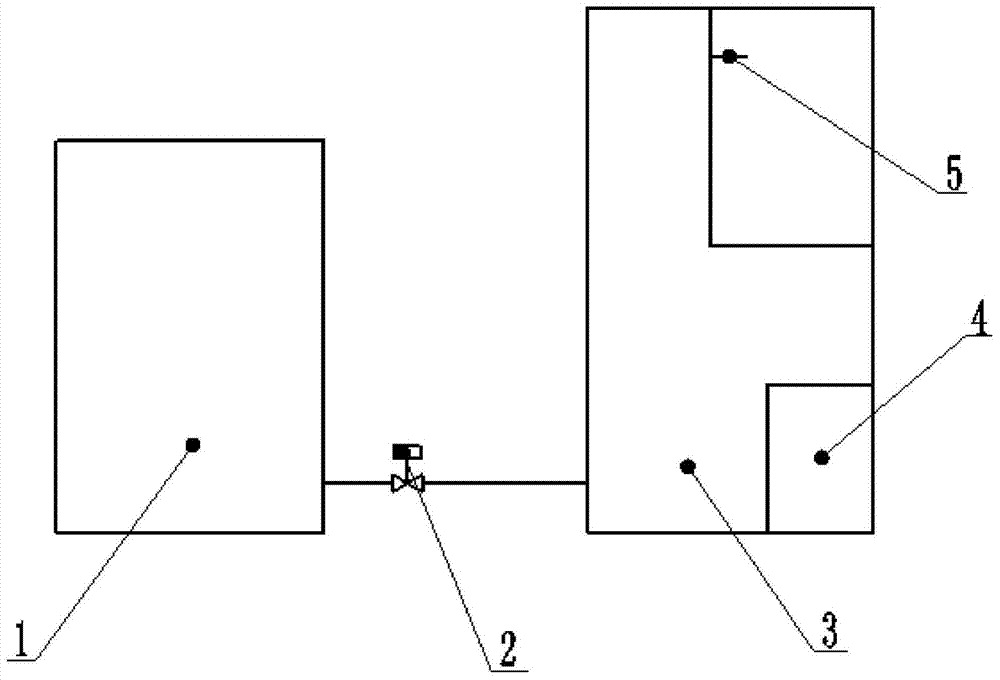

[0010] The main contents of the system include: a freezer 1, a solenoid valve 2, a slicer 3, a control device 4 and a temperature sensor 5, characterized in that the freezer 1 is connected to the slicer 3 through a pipeline, and the pipeline is installed with Solenoid valve 2, a control device 4 is installed in the slicer 3, and the control device 4 is connected with the terminal of the solenoid valve 2 through a wire, a temperature sensor 5 is installed in the slicer 3, and the temperature sensor 5 is wired The column is connected to the control device 4 by means of wires.

[0011] The control device 4 includes a signal processing module.

[0012] The control device 4 includes a display module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com