Machining device and machining technology for holes of driving axle housing of industrial vehicle

A technology for driving axle housings and industrial vehicles, which is applied in the directions of reaming devices, reaming devices, positioning devices, etc., which can solve the problems of unguaranteed processing accuracy, high labor intensity of workers, and low unit work efficiency, so as to improve the processing quality , Reduce the labor intensity of workers, improve the effect of labor production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

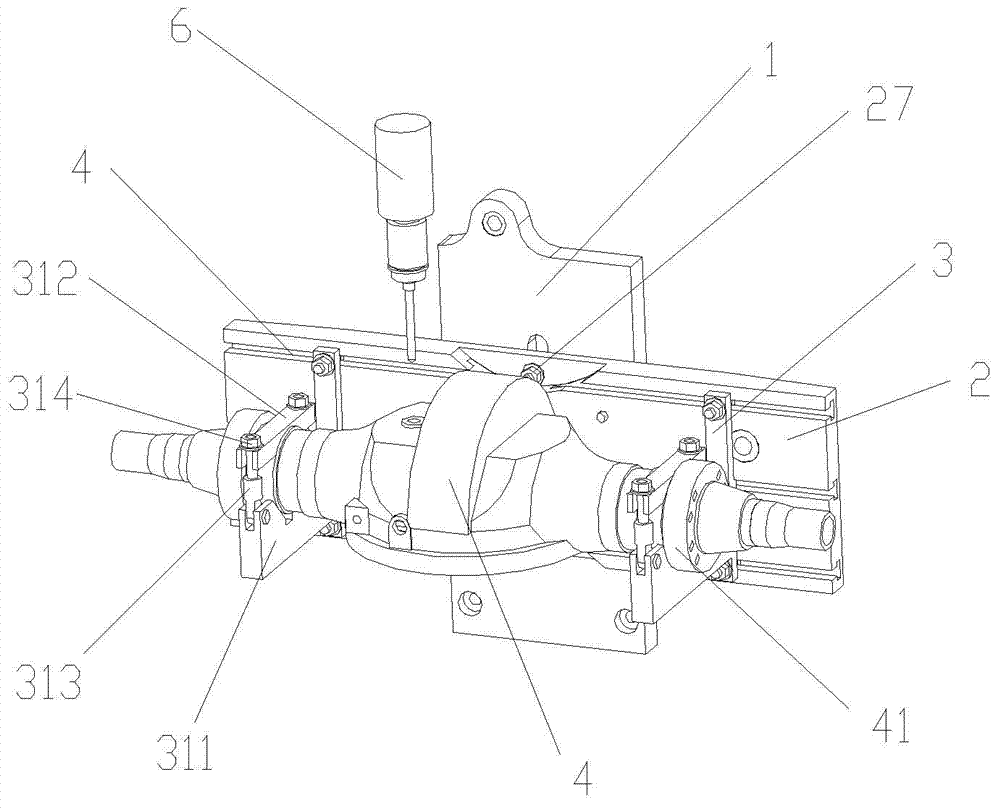

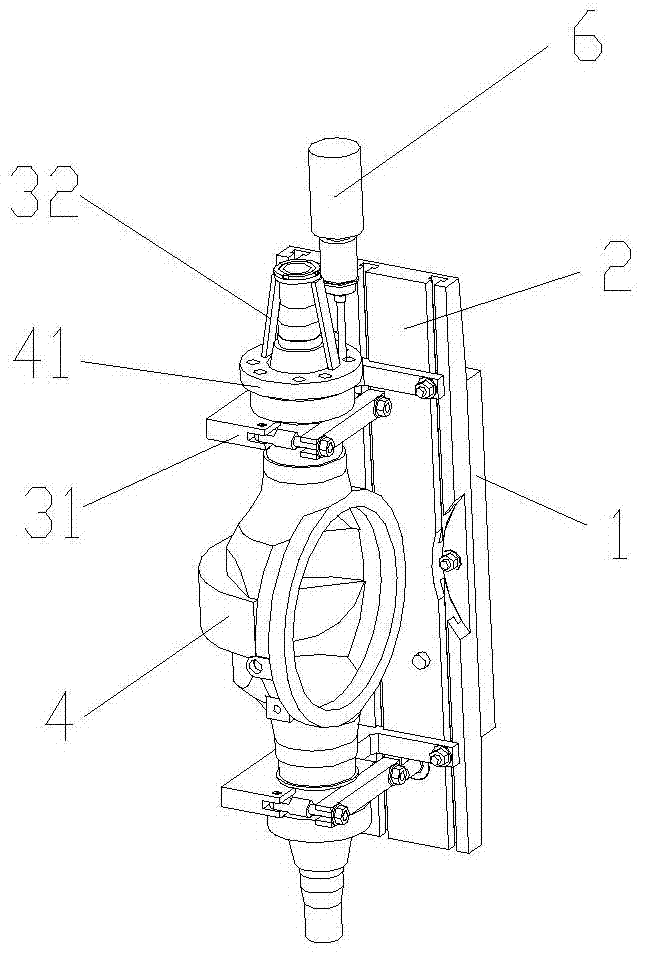

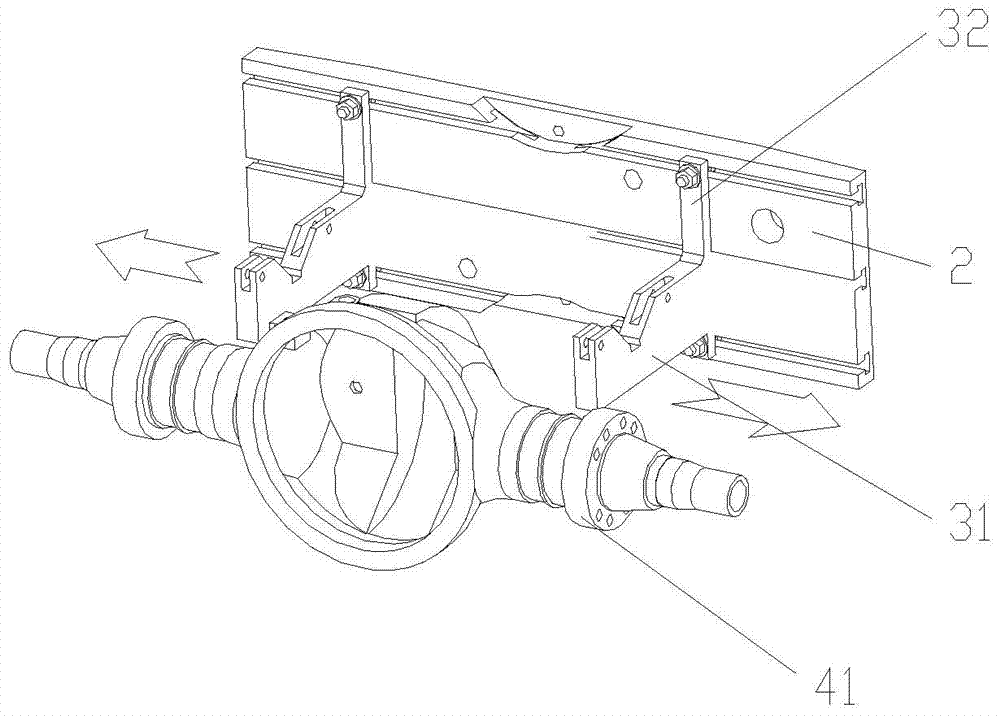

[0030] see figure 1 , a hole processing device for an industrial vehicle drive axle housing provided by the present invention includes a rotary base 1 and a rotary frame 2, one side of the rotary frame 2 is rotatably supported on the rotary base 1, and the other side of the rotary frame 2 is provided with a drive axle housing Mounting fixture 3, combined with figure 2 and image 3 The drive axle case installation fixture 3 includes a clamping seat 31 and a drilling jig 32, the clamping seat 31 is symmetrically clamped on the inside of the flange plate 41 of the drive axle case 4, and the drilling fixture 32 is symmetrically sleeved on the drive axle case 4 outside of the flange plate 41, combined with Figure 4 , the drilling jig 32 includes a limit ring 321 flush with the end of the drive axle housing 4, and a drilling seat 322 concentrically arranged with the limit ring 321, and a fixed support is connected between the limit ring 321 and the drilling seat 322 Bar 323, dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com