Oil injection device for central shaft of claw pole type step motor shell

A technology of stepping motor and oil injection device, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc. Product quality, high reliability, and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

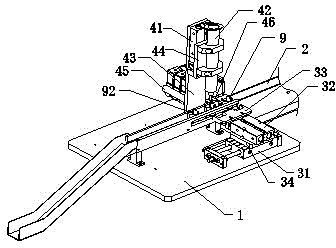

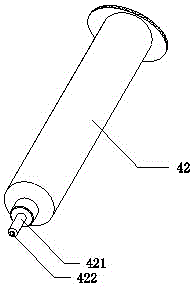

[0019] refer to figure 1 , figure 2 , figure 1 , figure 2 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, a claw-pole type stepping motor casing central shaft oiling device includes a workbench 1, a casing feeding channel 2, a casing feeding mechanism, an oiling mechanism, Block material cylinder 45, casing detection sensor 46; Wherein casing feeding channel 2 is fixedly arranged on the workbench 1, and casing feeding channel 2 is provided with the guide rail corresponding to casing 9, in the present embodiment, central axis 92 It is installed and positioned in the casing 9, and the guide rail can be docked with the equipment in the previous process to realize automatic feeding.

[0020] As shown in the figure, the casing feeding mechanism includes a pusher cylinder 31 fixedly arranged on the workbench 1 and a clamping cylinder 32 arranged on the pusher cylinder 31, and the ejector rod of the clamping cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com