High voltage belt shielding power socket

A technology of power sockets and high-voltage belts, applied in the direction of connecting parts protective grounding/shielding devices, circuits, electrical components, etc., can solve the problems of blocked or blocked shielding conduction, bulky insulating mounting plate, unsuitable power sockets, etc. Improve precision, high production efficiency, and ensure the effect of product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

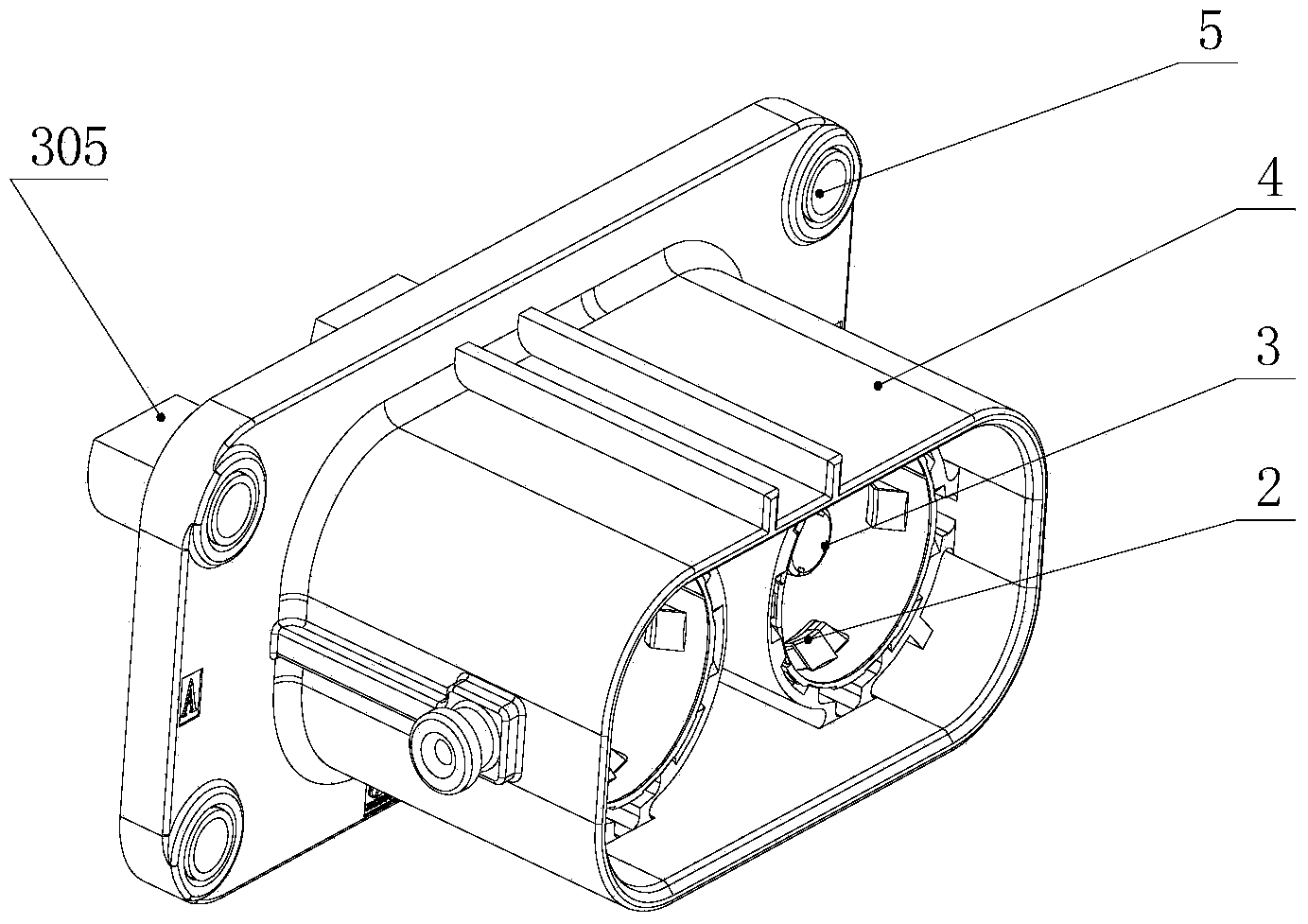

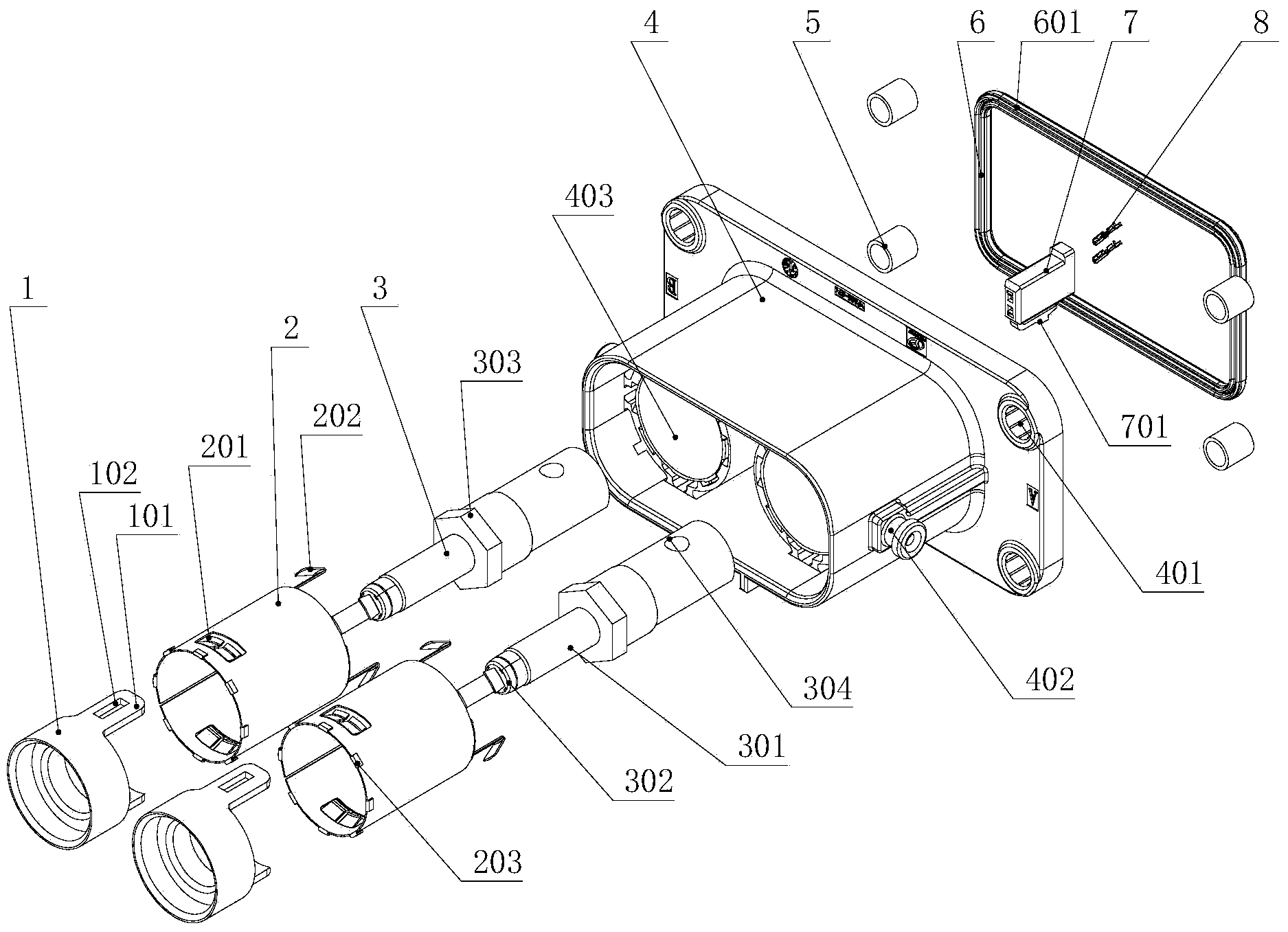

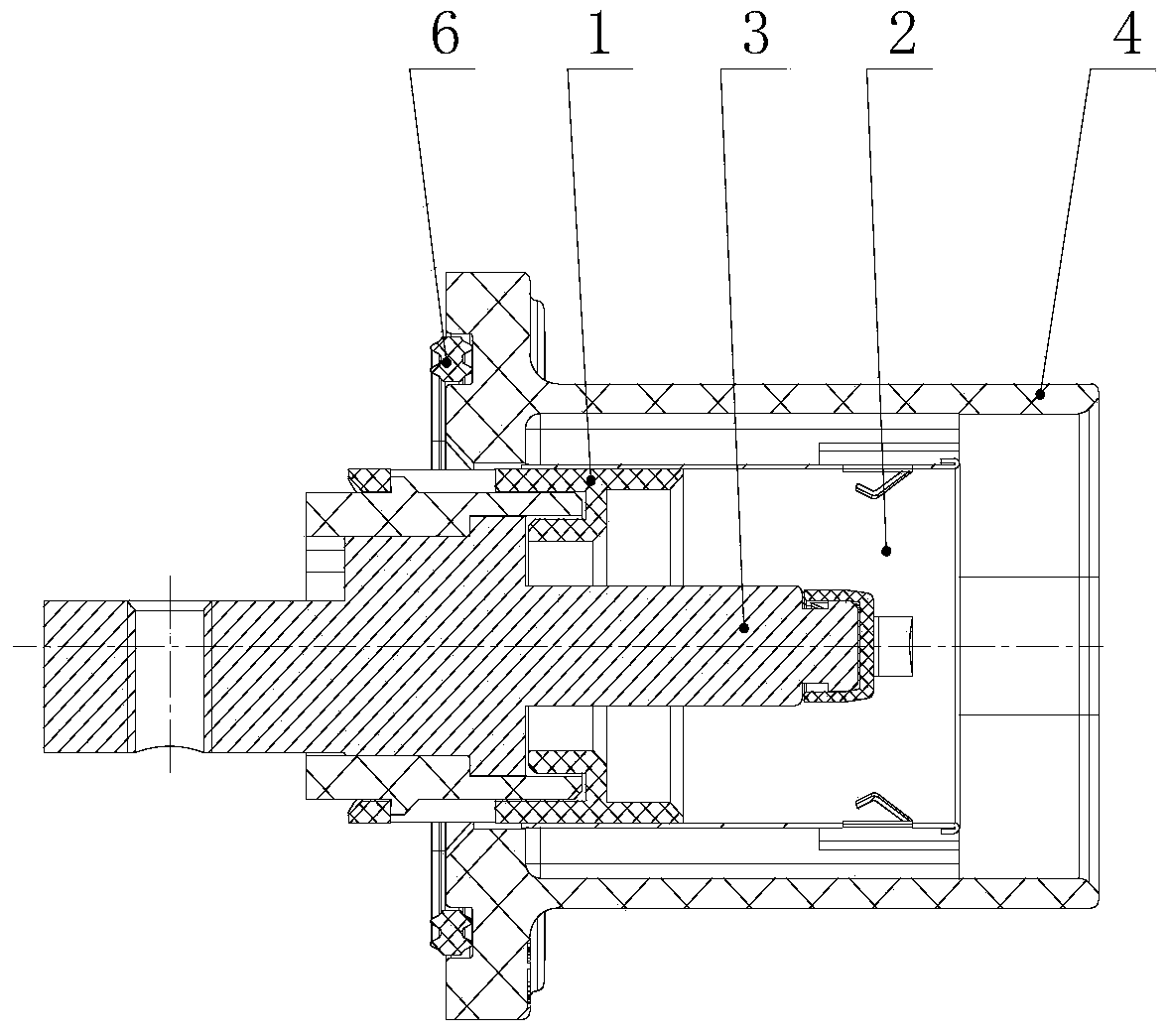

[0031] Such as Figure 1 to Figure 5 As shown, a high-voltage shielded power socket includes a pin fixing cover 1, a shield cover 2, a pin assembly 3, a socket shell 4, a screw sleeve 5, a gasket 6, a sheath 7 and a signal hole 8, and the socket shell 4. The whole body may be rectangular. A flange is provided at one end of the socket housing 4, or a flange is provided at the waist thereof. A hollow cylindrical rotating shaft 402 is provided on opposite sides of the socket housing 4; in other words, two hollow cylindrical rotating shafts 402 are symmetrically arranged between the insertion opening and the flange on both sides of the socket housing 4; Two shielding installation cylinders 403 are arranged inside the socket housing 4, and the bottom of the insertion end of the shielding installation cylinder 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com