String vibration period experiment instrument with vibration motor as wave source

A vibration motor and experimental instrument technology, applied in the direction of instruments, educational tools, teaching models, etc., can solve the problems of the influence of experimental teaching quality, the demonstration effect is not obvious, and the equipment structure is complicated, so as to achieve excellent experimental teaching quality, easy adjustment and measurement , the effect of high experimental precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

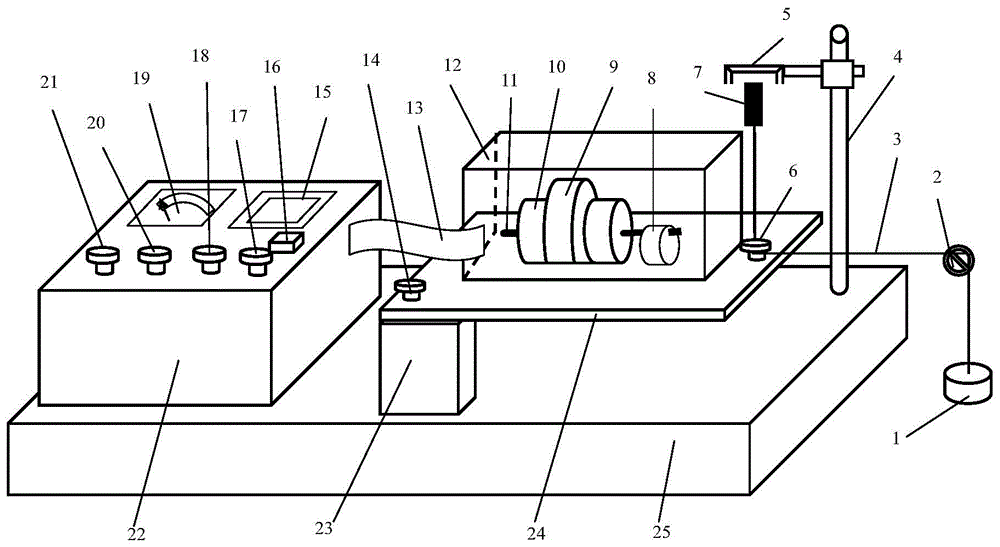

[0015] see figure 1 , the vibrating motor is the string vibration cycle experimental instrument of wave source, and it comprises experimental instrument main body, is provided with base 25 at the bottom of described experimental instrument main body, and base 25 and vibrating motor part fixing plate 24 are supported and fixed by support column 23, and support column 23 Single-point support fixes the flat plate 24 and fixes it with screws 14. Vibration motor part 12 is installed on the above-mentioned vibrating motor parts fixed flat plate 24, and vibrating motor 10 is installed in the vibrating motor part 12, and vibrating motor 10 is fixed on the fixed flat plate 24 by vibrating motor fixing frame 9. An eccentric block 8 is installed on the right side of the outer shaft 11 of the vibration motor 10 . A baffle plate 7 is also installed on the above-mentioned fixed plate 24 and fastened with fastening screws 6 . The photoelectric door frame 4 and the photoelectric door 5 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com