An enterprise railway logistics control system and its calculation method

A control system and logistics system technology, applied in the field of enterprise railway logistics management system, can solve the problems of large fluctuations in the number of daily loading, low efficiency, and failure to meet the time requirements of management, so as to improve the efficiency of vehicle use and accelerate the turnover of vehicles , the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

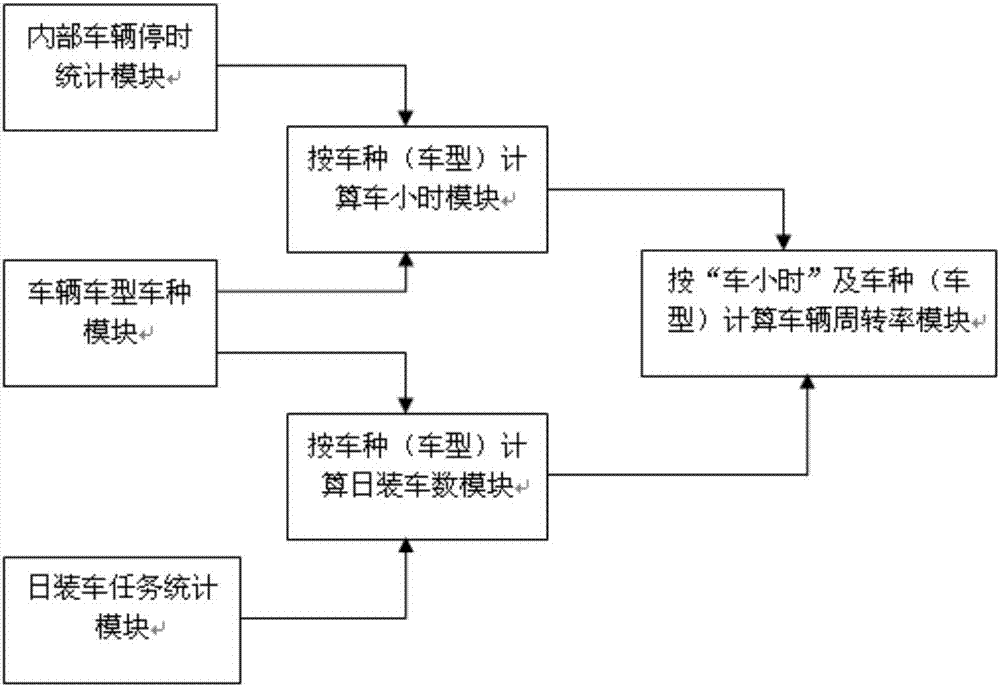

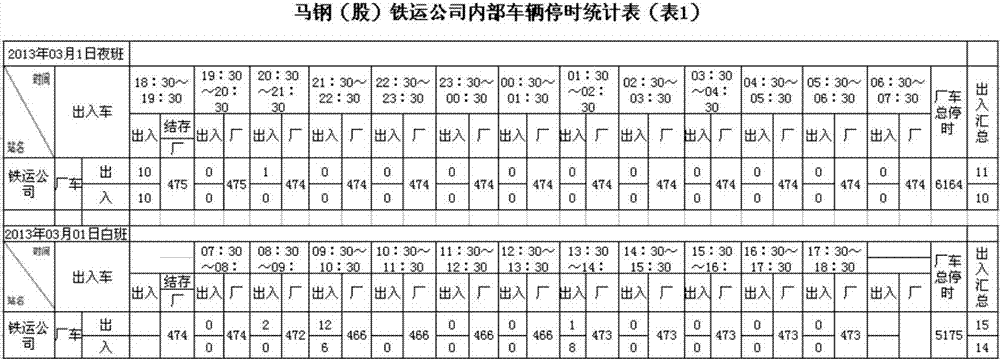

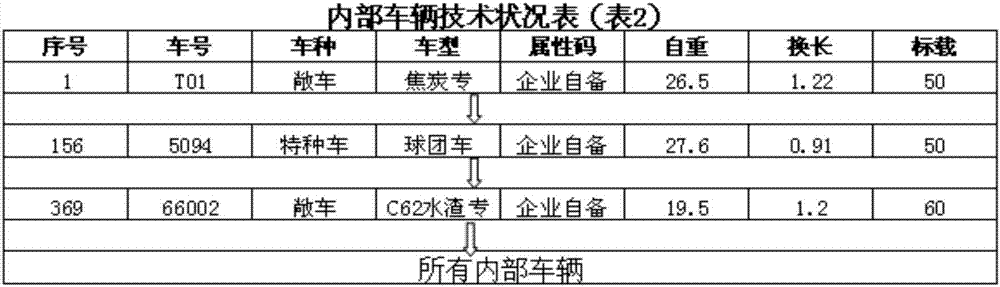

[0039] An enterprise railway logistics management system, including each station in the enterprise's internal railway management, with a logistics management system dedicated network and a logistics server; various data calculation modules related to the turnover rate of freight cars run in the server, and each module calculates automatically on a daily basis Relevant data, and finally form a statistical table of vehicle turnover rate by vehicle type (model). Each station is equipped with a logistics system operation terminal. Each terminal is connected to the system server through the system private network, and the terminal is used to operate and query the statistics of the turnover rate of trucks. surface.

[0040] A calculation method of vehicle turnover rate: based on the calculatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com