Reaction cup loading mechanism for full-automatic chemiluminiscence immune analyzer

An automatic chemistry and luminescence immune technology, applied in analytical materials, instruments, biological tests, etc., can solve the problems of low degree of automation, inability to load the cuvette, and inability to meet the continuous operation of the instrument, and achieve the effect of a compact overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

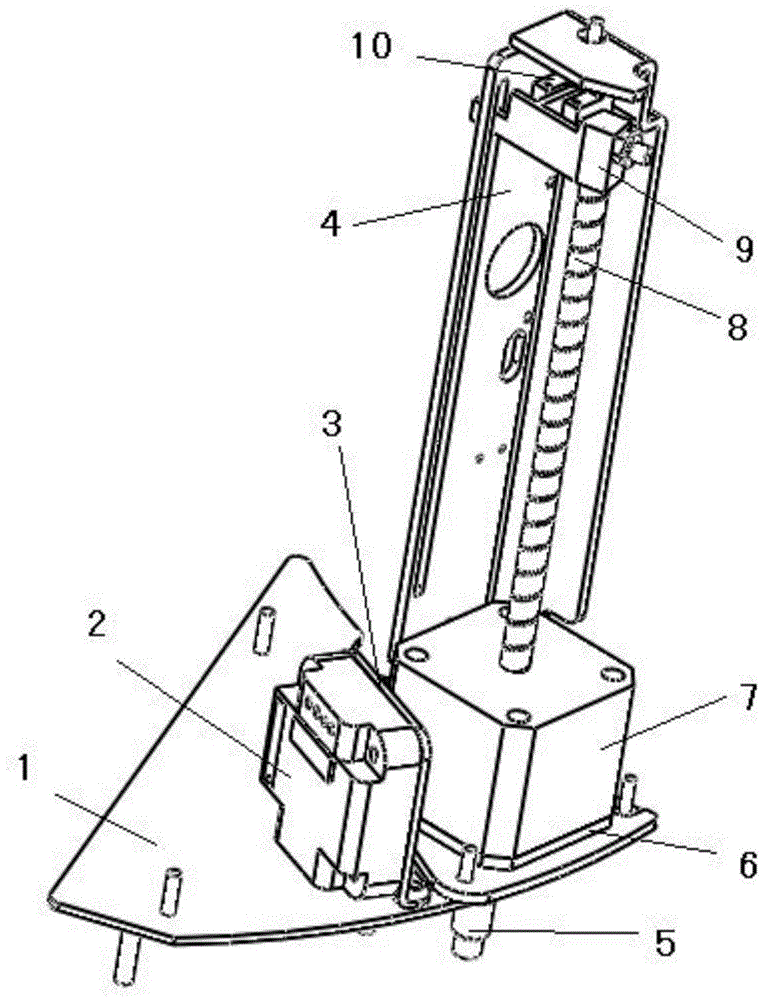

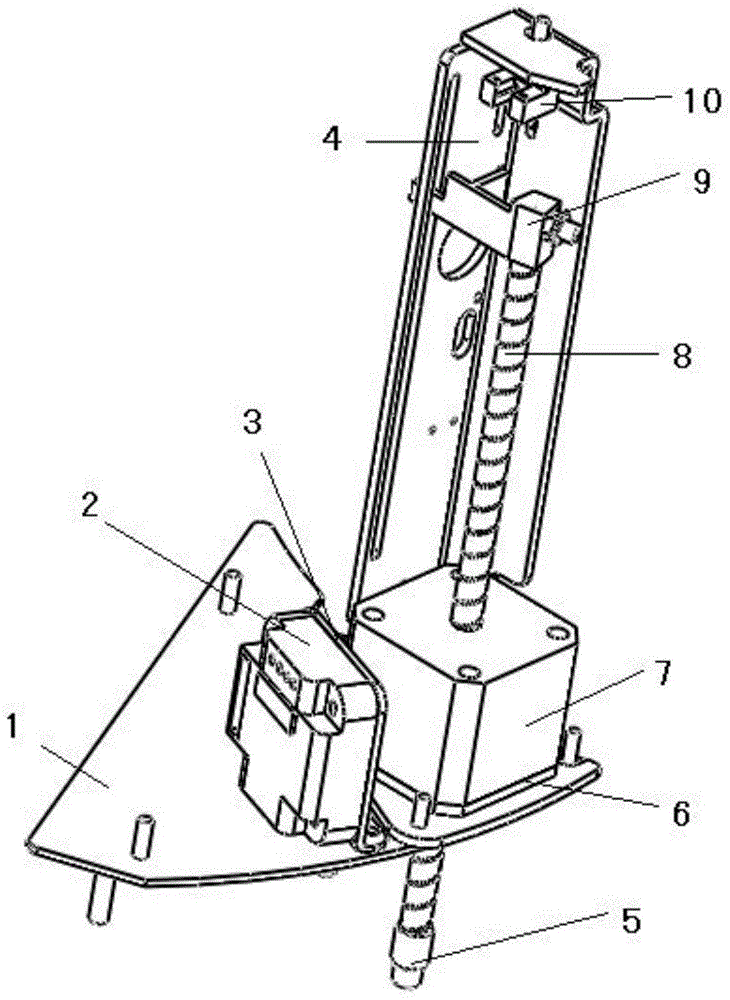

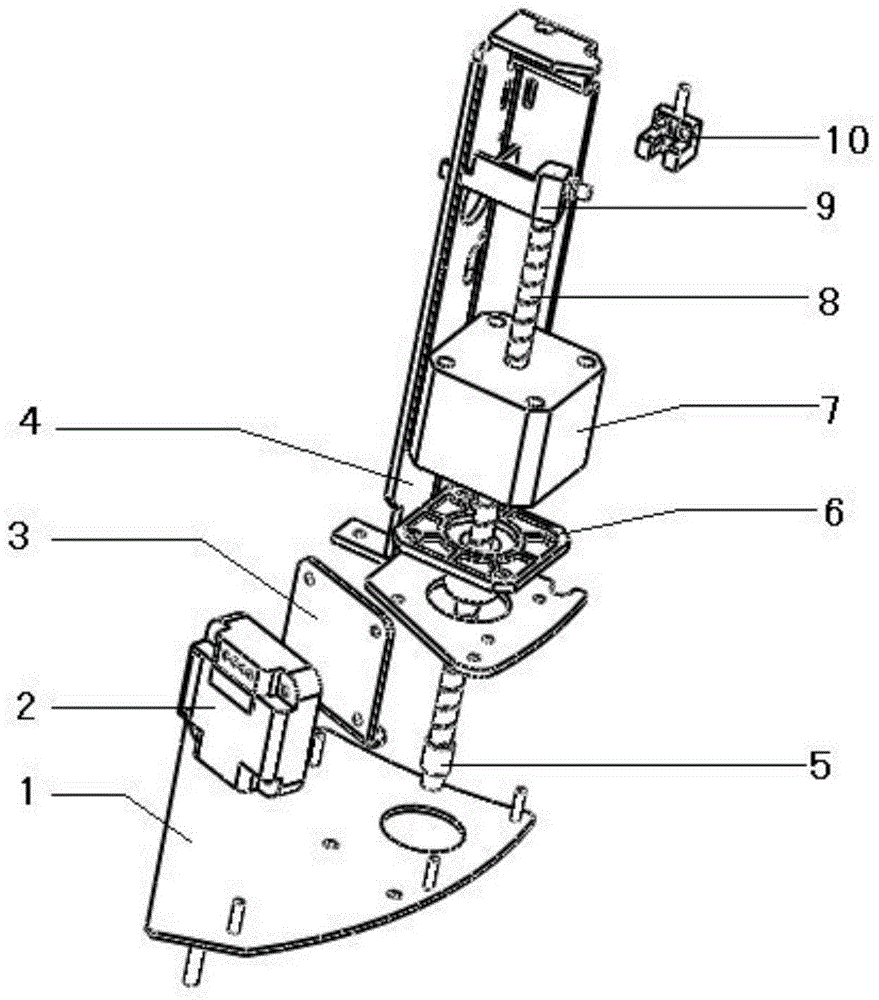

[0020] See attached figure 1 to attach image 3 As shown, it is a cuvette loading mechanism for a fully automatic chemiluminescent immunoassay analyzer according to an embodiment of the present invention, including a fixed plate 1, which is a flat plate structure, and acts as a load-bearing support, vertically on the fixed plate 1 A support 4 and a module mounting plate 3 are provided, and the module mounting plate 3 is used to fix the motor drive module 2; the screw motor 7 is fixed on the support 4, and the screw 8 motor 7 and the support 4 There is also a guide and positioning block 6 fixed between them. The center of the guide and positioning block 6 is a cylindrical through hole protruding downwards. The screw mandrel 8 is a threaded hollow rod-shaped structure, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com