Rubber stopper quality testing device and testing method

A quality inspection method and rubber stopper technology, applied in the direction of measuring devices, optical devices, and optical testing of flaws/defects, can solve problems such as high production costs, huge devices, and high manpower, material resources, and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

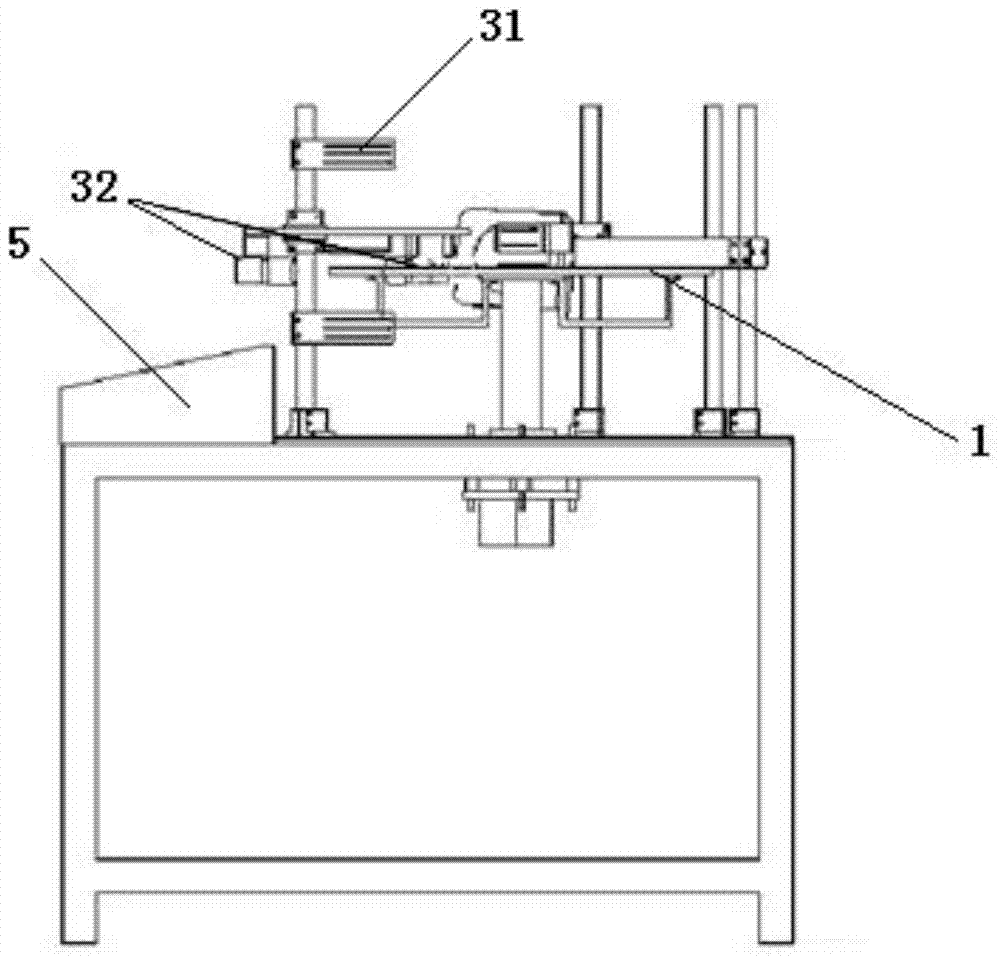

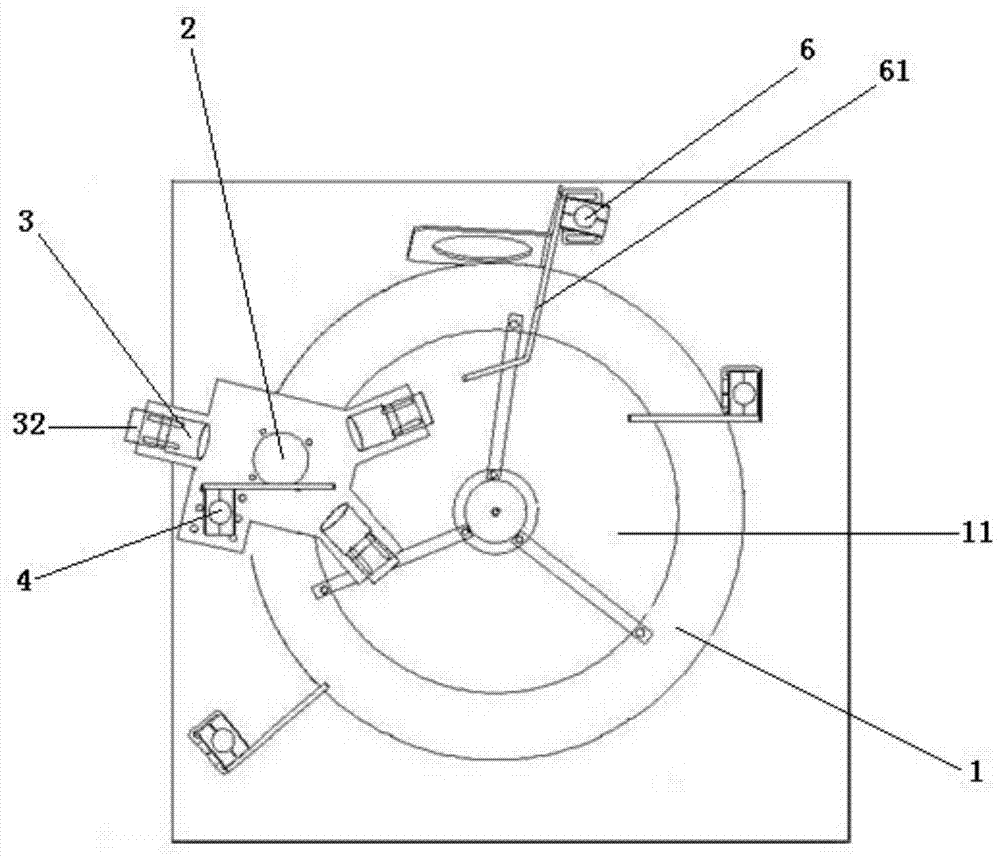

[0069] Below in conjunction with accompanying drawing of description, the present invention will be further described.

[0070] like figure 1 and figure 2 As shown, a rubber stopper quality detection device at least includes the following components:

[0071] The uniform rotating platform 1 is used to transport the rubber stopper to be tested;

[0072] The detection position 2 is the position used to provide detection for the transported rubber stoppers to be detected in the uniform rotation platform 1;

[0073] A fixed-focus camera 3 is used to photograph the rubber plug to be detected at the detection position 2;

[0074] The photoelectric switch 4 is fixed on one side of the detection position 2, and is used to trigger the fixed-focus camera 3 to take pictures;

[0075] A light source (not shown in the figure) is used to provide detection illumination;

[0076] The industrial computer 5 is used to detect and process the rubber stopper image collected by shooting, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com