Evaporative condensers for peak cooling in power plants

An evaporative condenser and peak cooling technology, which is applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problem of limited condensation efficiency of evaporative condensers, reduced heat transfer temperature difference of air-cooled condensers, and Surface dirt and other problems, to achieve the effect of increasing the latent heat of vaporization, improving heat transfer efficiency, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

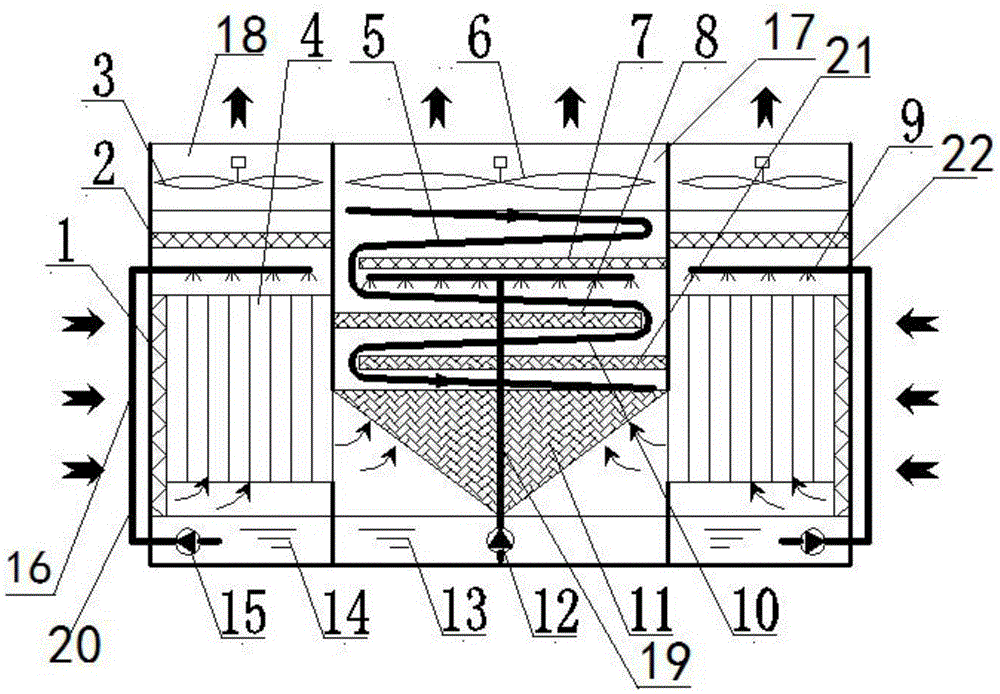

[0026] The evaporative condenser for power plant peak cooling of the present invention has a structure such as figure 1 As shown, it includes a condenser shell, and an air inlet 16 is arranged on the opposite side walls of the condenser shell, and a packing-coil compound evaporative cooling unit is arranged in the condenser shell, and the packing-coil compound A standpipe type indirect evaporative cooling unit is symmetrically arranged on the left and right sides of the evaporative cooling unit, and an air outlet a17 is arranged on the top wall of the condenser shell corresponding to the filler-coil composite evaporative cooling unit. An air outlet b18 is respectively arranged on the top wall of the corresponding condenser shell above the vertical pipe type indirect evaporative cooling units.

[0027] A fan a6 is arranged in the air outlet a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com