Process for producing brick by waste heat drying sludge from sintered brick production line tunnel kiln

A technology for drying sludge and production lines, applied in waste heat treatment, lighting and heating equipment, furnace types, etc., can solve problems such as environmental pollution and resource waste, and achieve the effects of convenient operation, energy saving, and simple overall process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

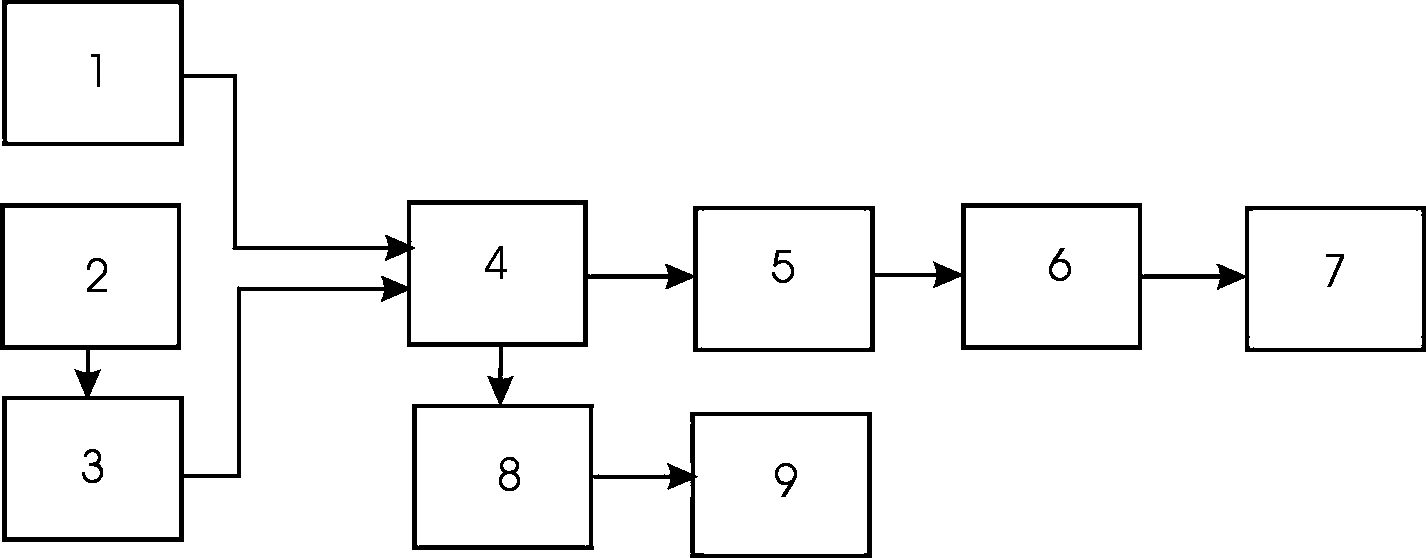

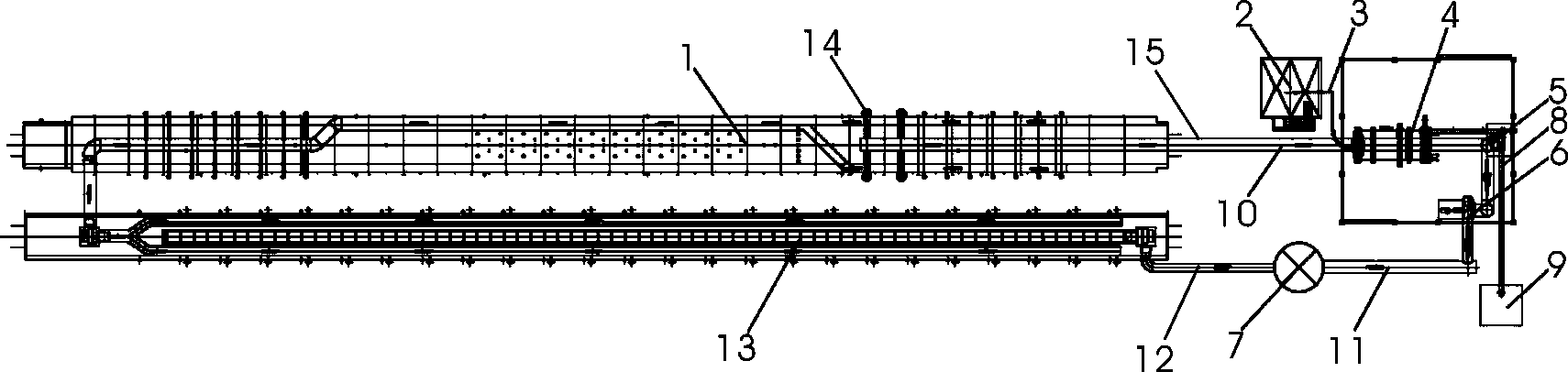

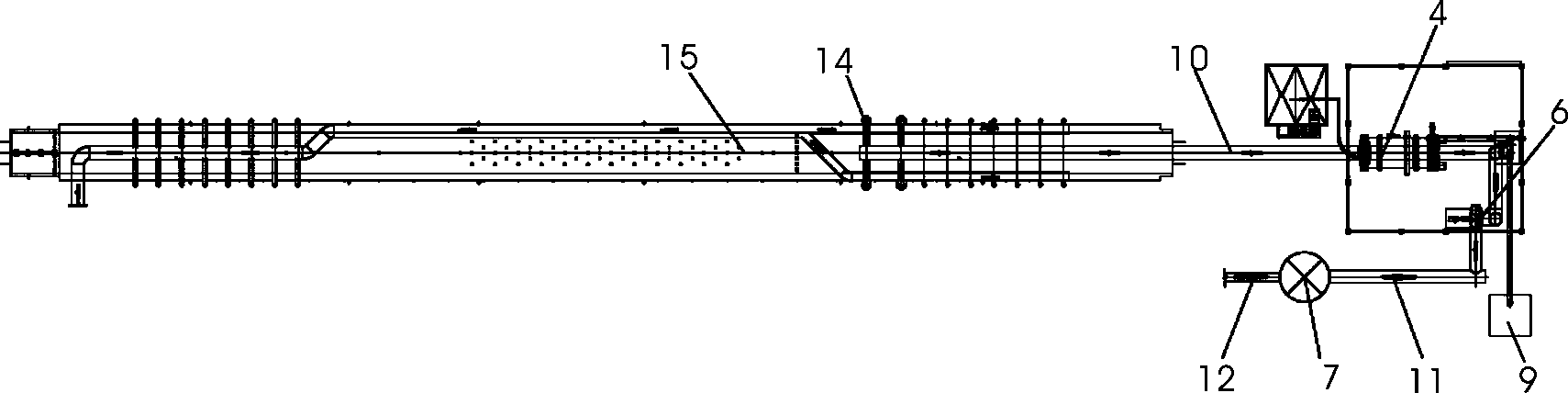

[0021] Now refer to the attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 , are described as follows in conjunction with the examples: The process for making bricks using the waste heat of the tunnel kiln in the sintered brick production line according to the present invention includes waste heat 1 in the cooling section of the roasting kiln, wet sludge silo 2, sludge delivery pipe 3, and sludge drying Machine 4, cyclone dust collector 5, induced draft fan 6, desulfurization tower 7, screw conveyor 8, dry sludge silo 9, air intake pipe 10, drying workshop inlet and desulfurization tower outlet pipe 11, drying kiln inlet and desulfurization tower outlet Air duct 12, drying kiln 13, auxiliary air duct 14 for extracting waste heat and main air duct 15 for extracting waste heat. The wet sludge is transported to the wet sludge silo 2 after summarization, and the sludge delivery pipe 3 is set from the wet sludge silo 2 to connect to the sludge dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com