All-prefabricated fence

A technology of prefabricated assembly and enclosure, applied in the direction of enclosures, building types, buildings, etc., to achieve the effect of less land occupation, high degree of mechanized operation, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

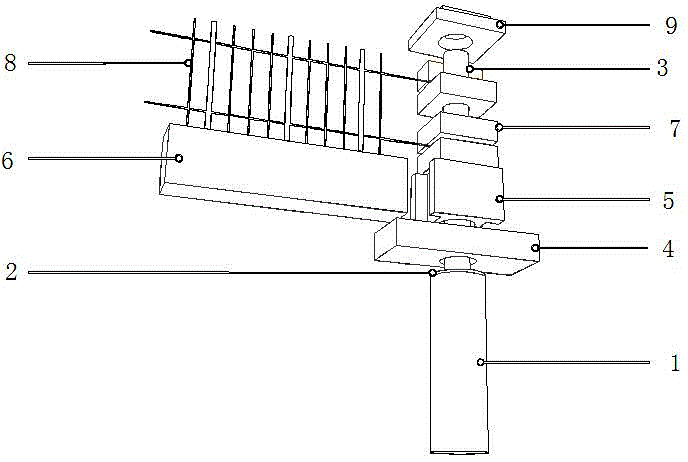

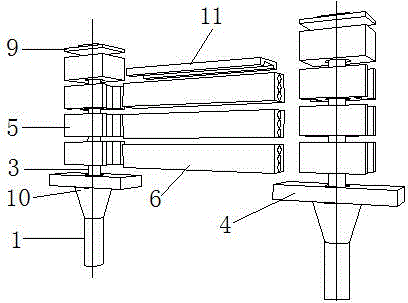

Method used

Image

Examples

Embodiment

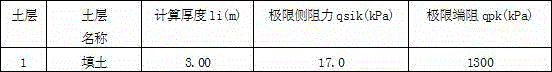

[0039] Example: A company invested in the construction of a chemical plant in the Yanhua Industrial Park of Huai'an City, Jiangsu Province. The project covers an area of 75 acres and requires the construction of a factory fence 885 m, using the fully prefabricated hollow wall of the application.

[0040] 1. The dimensions of each part of the wall are as follows:

[0041] 1, variable section pipe pile : Select custom-made C60 mixed-reinforced prestressed concrete pipe piles Φ300 X 100; the outer diameter of the pipe pile is 30 cm, the inner diameter of the pipe pile is 10 cm, driven into the ground 200-250 cm, the distance between the centers of the pipe piles is 250 cm; the top of the pipe pile is 20 cm It is a thickened section with an outer diameter of 40 cm and an inner diameter of 10 cm; the thickened section is 20 cm downwards as a transition section, from Φ400 X 100 to Φ300 X 100; the thickened section and the transition section are reinforced; the supporting ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com