A kind of processing method of tc4-dt titanium alloy bar

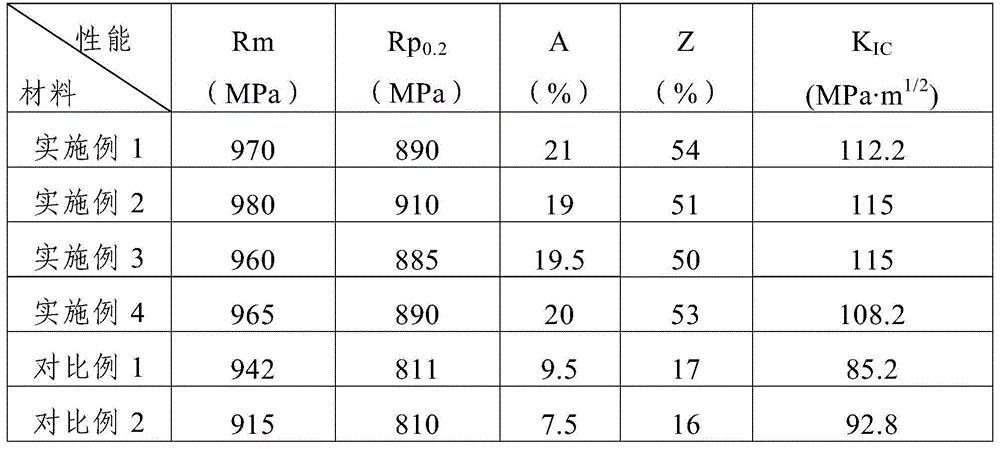

A TC4-DT and processing method technology, which is applied in the processing field of TC4-DT titanium alloy bars, can solve the problems of comprehensive matching, disadvantage, poor alloy plasticity, etc., and achieve the effect of improving strength, overall performance and fracture toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The processing method of the present embodiment TC4-DT titanium alloy bar comprises the following steps:

[0019] Step 1. Use a 2,500-ton fast forging machine to carry out billet forging on the TC4-DT titanium alloy ingot with a specification of Ф320mm, and obtain the first forging billet after air cooling; the billet forging adopts the forging method of repeatedly upsetting and elongating, It is completed in one fire. The initial forging temperature of blank forging is 165°C above the β transformation point, the final forging temperature of blank forging is 70°C below the β transformation point, and the cumulative deformation of blank forging is 70%; The first forged billet processed in this embodiment is a round billet with a cross-sectional diameter of 175mm;

[0020] Step 2: Use a 2,500-ton fast forging machine to perform intermediate forging on the first forging billet described in step 1, and obtain the second forging billet after air cooling; the intermediate for...

Embodiment 2

[0025] The processing method of the present embodiment TC4-DT titanium alloy bar comprises the following steps:

[0026] Step 1. Use a 2,500-ton fast forging machine to carry out billet forging on the TC4-DT titanium alloy ingot with a specification of Ф460mm, and obtain the first forging billet after air cooling; the billet forging adopts the forging method of repeatedly upsetting and elongating, It is divided into two fires to complete. The initial forging temperature of each billet forging is 180°C above the β transformation point, and the final forging temperature of each billet forging is 80°C below the β transformation point. The cumulative amount of deformation is 80%; the first forging billet processed in this embodiment is a round billet with a cross-sectional diameter of 206mm;

[0027] Step 2: Use a 2,500-ton fast forging machine to perform intermediate forging on the first forging billet described in step 1, and obtain the second forging billet after air cooling; t...

Embodiment 3

[0032] The processing method of the present embodiment TC4-DT titanium alloy bar comprises the following steps:

[0033] Step 1. Use a 1,600-ton hydraulic press to carry out billet forging on the TC4-DT titanium alloy ingot with a specification of Ф460mm, and obtain the first forging billet after air cooling; Completed in one fire, the initial forging temperature of the blank forging is 200°C above the β transformation point, the final forging temperature of the blank forging is 100°C below the β transformation point, and the deformation of the blank forging is 60%; this embodiment The processed first forging billet is a round billet with a section diameter of 290mm;

[0034] Step 2: Use a 1,600-ton hydraulic press to carry out intermediate forging on the first forging billet described in Step 1, and obtain the second forging billet after air cooling; the intermediate forging adopts the forging method of repeated upsetting and elongation, and is completed in two fires , the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com