High-water-resistance polyurethane material for coal mine downhole gas sealing and preparation method thereof

A polyurethane material and gas technology, applied in the field of polyurethane materials, achieves the effects of high closed cell rate, high sealing performance and reduced content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

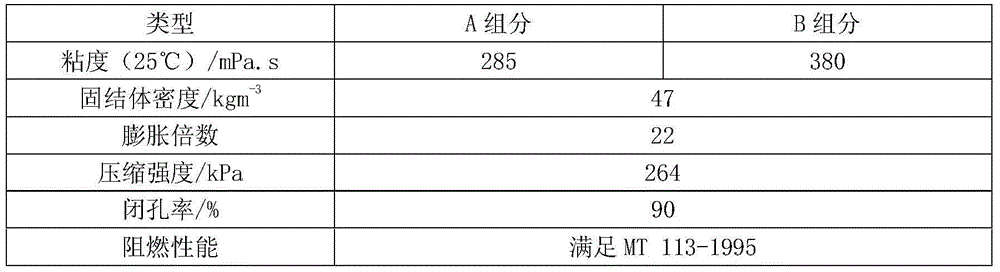

Embodiment 1

[0042] Preparation of component A:

[0043] Accurately measure 55 parts of polyether polyol 1 (4.1 functionality, molecular weight 550), 17 parts of polyether polyol 2 (3 functionality, molecular weight 300), and catalyst triethylenediamine Dabco 33-LV (American Air Chemical) 0.5 parts, surface active agent AK-8805 (Nanjing Meiside) 1.5 parts, blowing agent 1,1-dichloro-1-fluoroethane (HCFC-141b, Zhejiang FTSE) 13 parts and flame retardant phosphoric acid Thirteen parts of Trichloropropyl TCPP (Jiangsu Jacques) were put into the reactor, stirred and mixed for 2 hours, and then discharged, sealed and packaged;

[0044] Preparation of component B

[0045] Put the accurately measured vacuum dehydrated polyoxypropylene polyol GE-303 (3-functionality, molecular weight 300) (Shanghai Gaoqiao) and diphenylmethane diisocyanate MDI-50 into the reactor, and place the vacuum at 80~110, ℃ After stirring for 2 hours in an environment of 0.05-0.1 MPa, the polymerization inhibitor is added, and t...

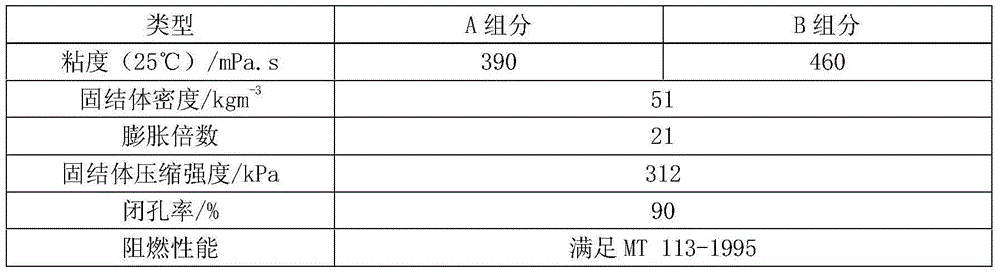

Embodiment 2

[0051] Preparation of component A:

[0052] Accurately measure 70 parts of polyether polyol 1 (4.6 functionality, molecular weight 580), 11 parts of polyether polyol 2 (2 functionality, molecular weight 210), and the catalyst pentamethyldiethylenetriamine PC CAT PMDETA (Germany Nitroil ) 0.3 parts, catalyst N, N-dimethylcyclohexylamine Polycat 8 (American Air Chemical) 0.2 parts, surfactant AK-158 (Nanjing Meiside) 1.5 parts, flame retardant dimethyl methyl phosphate DMMP (Qingdao Lianmei) 7 parts and 10 parts of foaming agent 1,1,1,3,3-pentafluoropropane Enovate 3000 (Honeywell, USA) are put into the reactor, stirred and mixed for 1 hour, then discharged, sealed and packaged;

[0053] Preparation of component B

[0054] Put the accurately measured vacuum dehydrated polyoxypropylene polyol GE-204 (2-functionality, molecular weight 400) (Shanghai Gaoqiao) and diphenylmethane diisocyanate MDI-100 into the reactor, and place the vacuum at 80~110, ℃ After stirring for 2 hours in an env...

Embodiment 3

[0060] Preparation of component A:

[0061] Accurately measure 60 parts of polyether polyol 1 (4.3 functionality, molecular weight 560), 15 parts of polyether polyol 2 (3 functionality, molecular weight 500), and catalyst N,N-dimethylbenzylamine Dabco BDMA (U.S. Air Chemical Industry) 0.5 parts, catalyst pentamethyldiethylene triamine Polycat 5 (U.S. Air Chemical Industry) 0.2 parts, surfactant L-5421 (American Momentum) 1.3 parts, flame retardant dimethyl methyl phosphate DMMP (Qingdao) United States) 4 parts, flame retardant trichloropropyl phosphate TCPP (Jiangsu Jacques) 5 parts and blowing agent 1,1,1,3,3-pentafluorobutane HFC-365 (Solvay company) 14 parts were put into the reaction In the kettle, stir and mix for 1 hour, then discharge and seal the package;

[0062] Preparation of component B

[0063] Put the accurately measured vacuum dehydrated polyoxypropylene polyol GE-210 (2-functionality, molecular weight 1000) (Shanghai Gaoqiao) and diphenylmethane diisocyanate MDI-50 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com