Salt-resistant polymer for oil displacement of oil field and preparation method thereof

A polymer and oil displacement technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of poor polymer viscosity increasing effect, poor salt resistance, application limitations, etc., and reduce the subsequent treatment process , Improve the effect of salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

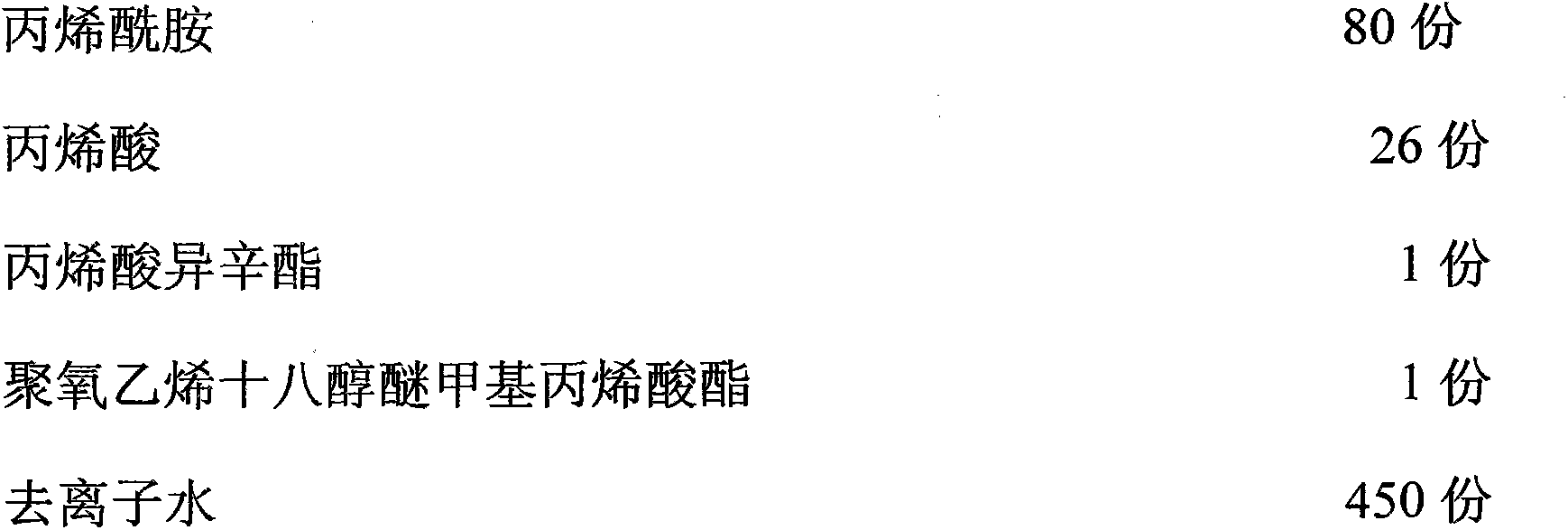

[0020] 1.1 The raw material composition (parts by weight) of the salt-resistant polymer used for oil field flooding of the present invention:

[0021]

[0022]

[0023] 1.2 The preparation method of the salt-resistant polymer used for oil field flooding of the present invention:

[0024] Dissolve acrylamide in deionized water to make an aqueous solution, add acrylic acid, sodium hydroxide to neutralize to a pH value of 8, add hydrophobic monomers, polyoxyethylene stearyl ether methacrylate or polyoxyethylene cetyl ether Methacrylate, chain transfer agent, stir evenly, transfer to the reactor, add 1# initiator through nitrogen for 30 minutes, add 2# initiator through nitrogen for 10 minutes, add 3# initiator through nitrogen for 10 minutes, continue to pass nitrogen until The reaction system has a temperature rise of 1-2°C, stop the nitrogen flow, wait for the reaction system to reach the peak temperature, the temperature is between 80-95°C, transfer the reactor to a 90°C...

Embodiment 2

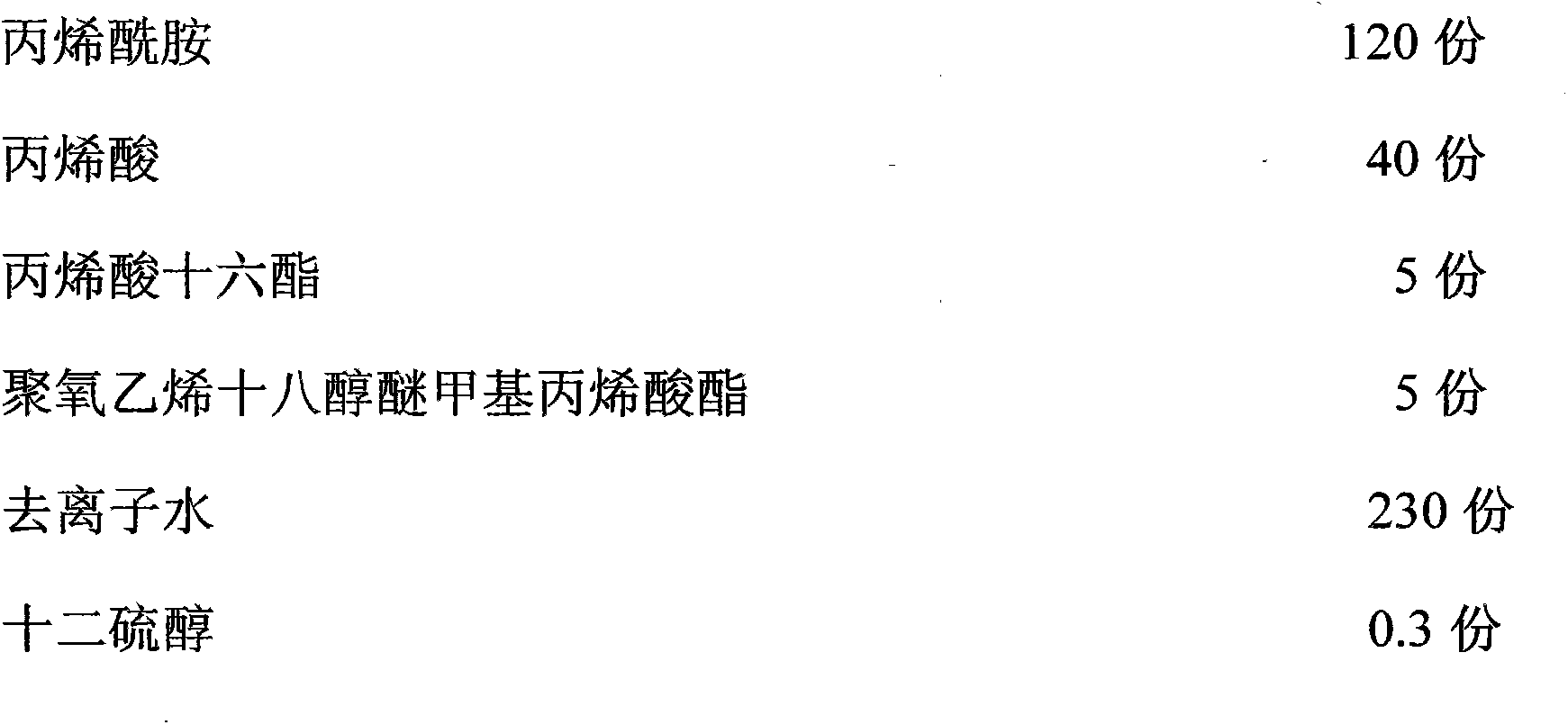

[0026] 2.1 The raw material composition (parts by weight) of the salt-resistant polymer used for oil field flooding of the present invention:

[0027]

[0028]

[0029] 2.2 The preparation method of the salt-resistant polymer used for oil field flooding of the present invention:

[0030] 1.2 with embodiment 1.

Embodiment 3

[0032] 3.1 The raw material composition (parts by weight) of the salt-resistant polymer used for oil field flooding of the present invention:

[0033]

[0034] 3.2 The preparation method of the salt-resistant polymer used for oil field flooding of the present invention:

[0035] 1.2 with embodiment 1.

[0036] The polymer mother liquor prepared by 5000mg / L embodiment 1-3 is diluted into 1000mg / L solution with simulated sewage (simulated sewage: 10000mg / LNaCl, 200mg / L (Ca 2+ , Mg 2+ )). The results are shown in Table 1.

[0037] Table 1

[0038]

[0039] As can be seen from Table 1, the salinity of the 1500ppm salt-resistant polymer solution used for oil field flooding of the present invention is 30000mg / LNaCl, 200mg / LCa 2+ , Mg 2+ The 90d viscosity retention rate in the solution is greater than 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com