Method for preparing high-viscosity cross-linking carboxymethyl starch

A cross-linked carboxymethyl, high-viscosity technology, used in the preparation of modified starch and food additives, can solve the problems of acid resistance, heat resistance, shear resistance, poor viscosity stability of paste liquid, etc. Good melting performance and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Weigh corn starch, sodium hydroxide, and chloroacetic acid according to the molar ratio of 1:1.85:0.85, and then uniformly disperse the corn starch in ethanol with a concentration of 90-95%, and add the weighed hydrogen at a temperature lower than 30°C Sodium oxide, and cross-linking agent epichlorohydrin with 0.15% starch weight, stir evenly, and ripen for 20-30 minutes, then add chloroacetic acid that has been weighed, keep 45-50°C for etherification reaction for 2.5h, and then use acid and, filtering and washing, drying at low temperature, and pulverizing to obtain the product high-viscosity cross-linked carboxymethyl starch.

Embodiment 2

[0015] Embodiment two: viscosity stability

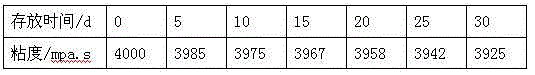

[0016] After measurement, the viscosity and storage time of the high-viscosity cross-linked carboxymethyl starch prepared by the preparation method of the present invention are shown in Table-1

[0017]

[0018] As shown in Table-1, the viscosity of the high-viscosity cross-linked carboxymethyl starch prepared by the present invention is increased, and the viscosity stability is greatly improved. The viscosity of the 2% aqueous solution is placed at room temperature for 30 days, and the viscosity drops by less than 5%. However, the viscosity of commercially available CMS drops rapidly, and the viscosity basically disappears after 15 days.

[0019] The paste liquid is boiled at 100°C for 60 minutes, and the viscosity increases slightly after cooling, showing high thermal stability. And commercially available CMS is boiled for 60 minutes, and the viscosity disappears substantially after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com