Rapid-separation aerator for cable production sewage treatment

A technology for producing sewage and aerators, applied in the field of aerators, can solve the problems of low efficiency of dissolved air and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

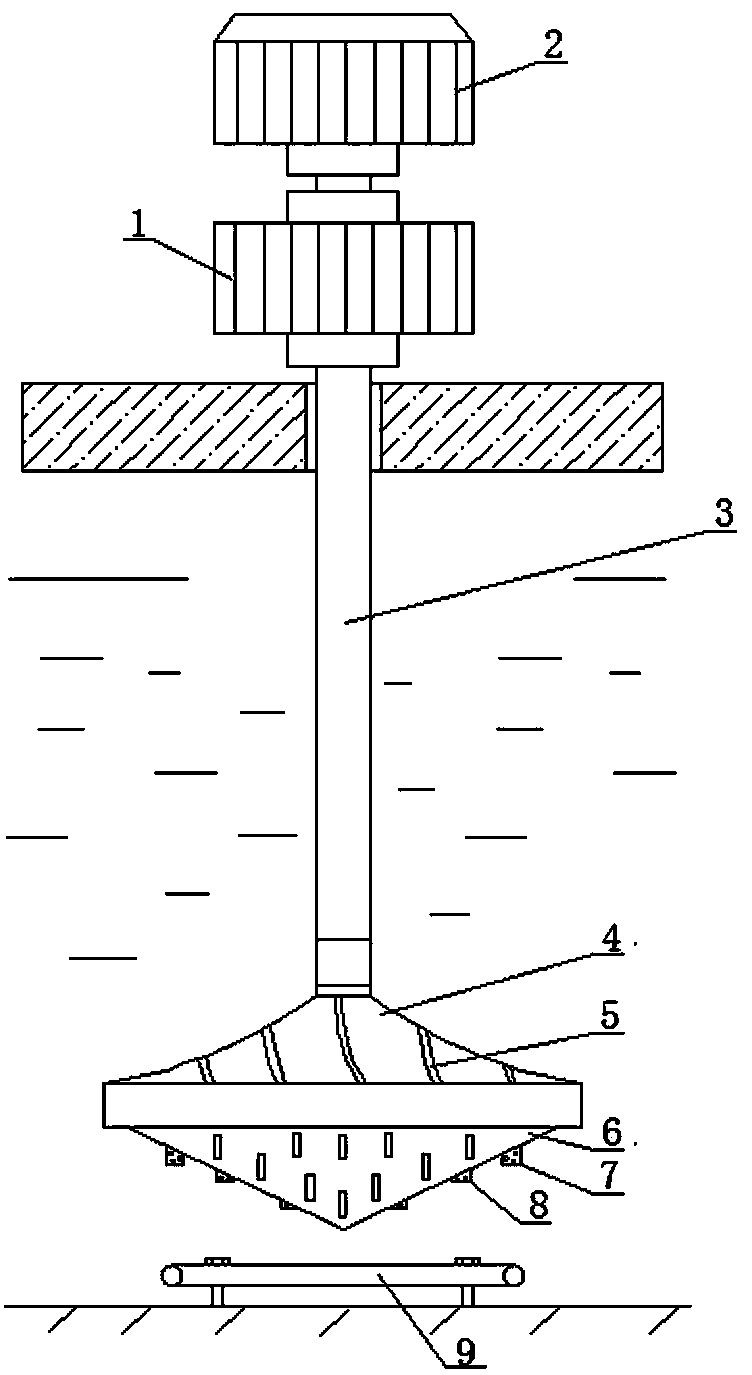

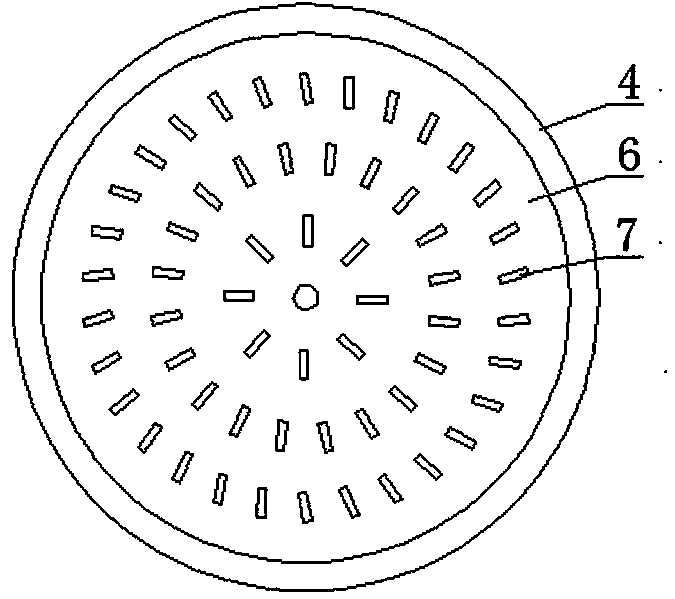

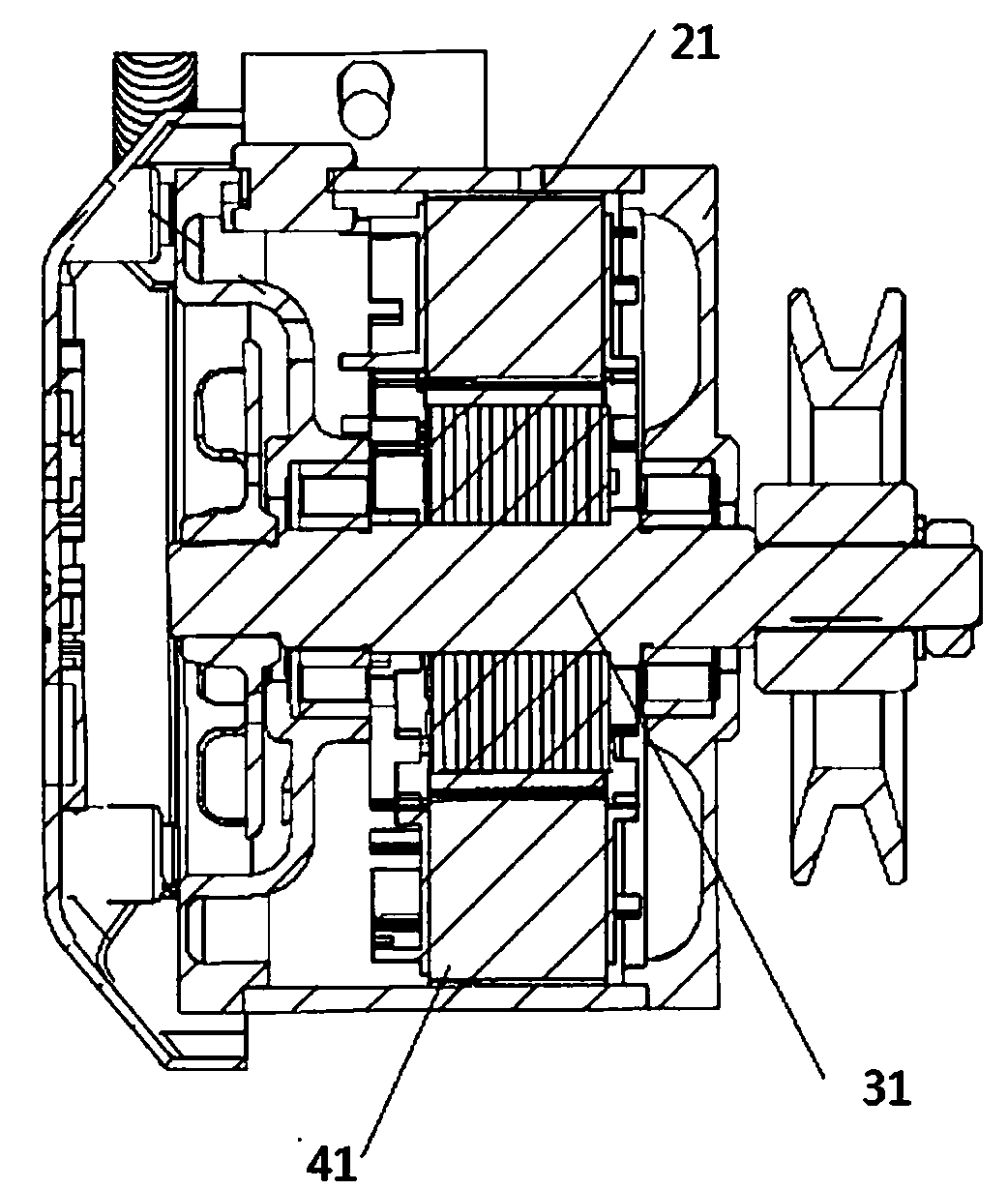

[0037] The quick-separated aerator for cable production sewage treatment in this embodiment includes a drive motor, the drive motor includes a casing, a stator assembly and a rotor assembly, the rotor assembly includes a motor shaft, and the motor shaft is connected to There is a rotating shaft, and the lower end of the rotating shaft is connected with a dispersing disc, and the lower part of the dispersing disc is equipped with an air distribution pipe. The lower surface of the disc is provided with a stirring device, and the stirring device includes a conical base, the bottom of the base is connected to the lower surface of the dispersion disc upwards, the outer wall of the base is connected with a stirring piece, and the center of the base The axis is on the plane where the stirring piece is located, and the stirring piece is also provided with a plurality of through holes.

Embodiment 2

[0039] The quick-separated aerator for cable production sewage treatment in this embodiment includes a drive motor, the drive motor includes a casing, a stator assembly and a rotor assembly, the rotor assembly includes a motor shaft, and the motor shaft is connected to There is a rotating shaft, and the lower end of the rotating shaft is connected with a dispersing disc, and the lower part of the dispersing disc is equipped with an air distribution pipe. The lower surface of the disc is provided with a stirring device, and the stirring device includes a conical base, the bottom of the base is connected to the lower surface of the dispersion disc upwards, the outer wall of the base is connected with a stirring piece, and the center of the base The axis is on the plane where the stirring piece is located, and the stirring piece is also provided with a plurality of through holes; the through holes are staggered on the stirring piece.

Embodiment 3

[0041] The quick-separated aerator for cable production sewage treatment in this embodiment includes a drive motor, the drive motor includes a casing, a stator assembly and a rotor assembly, the rotor assembly includes a motor shaft, and the motor shaft is connected to There is a rotating shaft, and the lower end of the rotating shaft is connected with a dispersing disc, and the lower part of the dispersing disc is equipped with an air distribution pipe. The lower surface of the disc is provided with a stirring device, and the stirring device includes a conical base, the bottom of the base is connected to the lower surface of the dispersion disc upwards, the outer wall of the base is connected with a stirring piece, and the center of the base The axis is on the plane where the stirring piece is located, and the stirring piece is also provided with a plurality of through holes; the through holes are staggered on the stirring piece. The through holes are obliquely opened on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com