Standard knot of tower crane

A technology for standard sections and tower cranes, applied in the direction of cranes, etc., can solve the problems of large force on the web, weak stability of the main chord, weak stability under compression, etc., so as to reduce the frequency of weld cracking and reduce the number of connection nodes. The effect of improving the overall safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

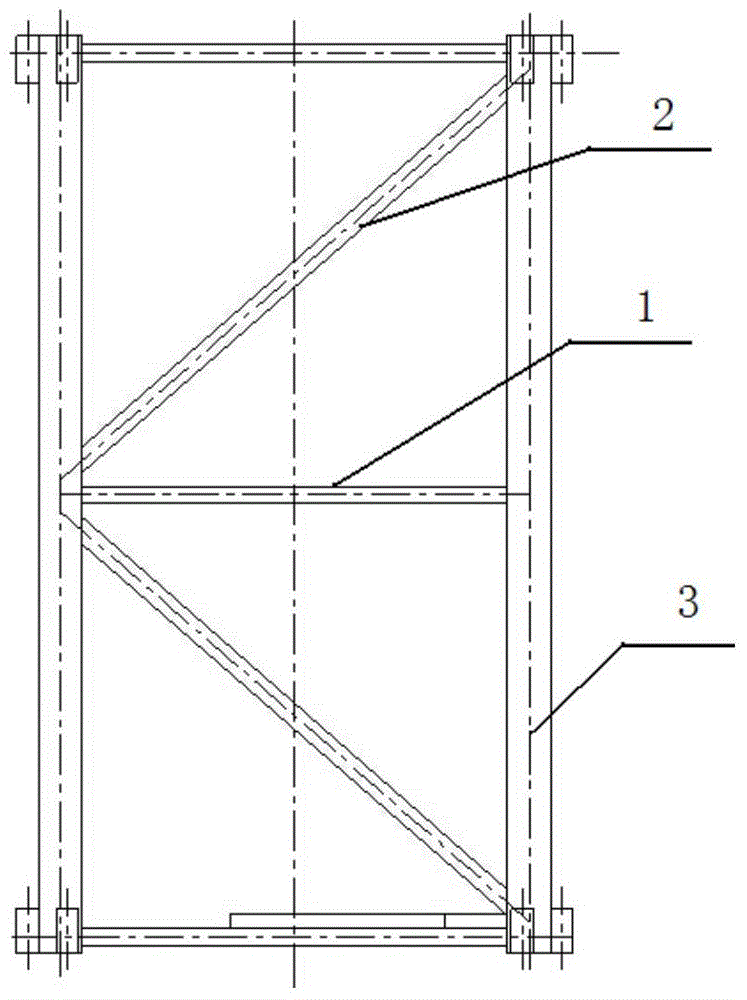

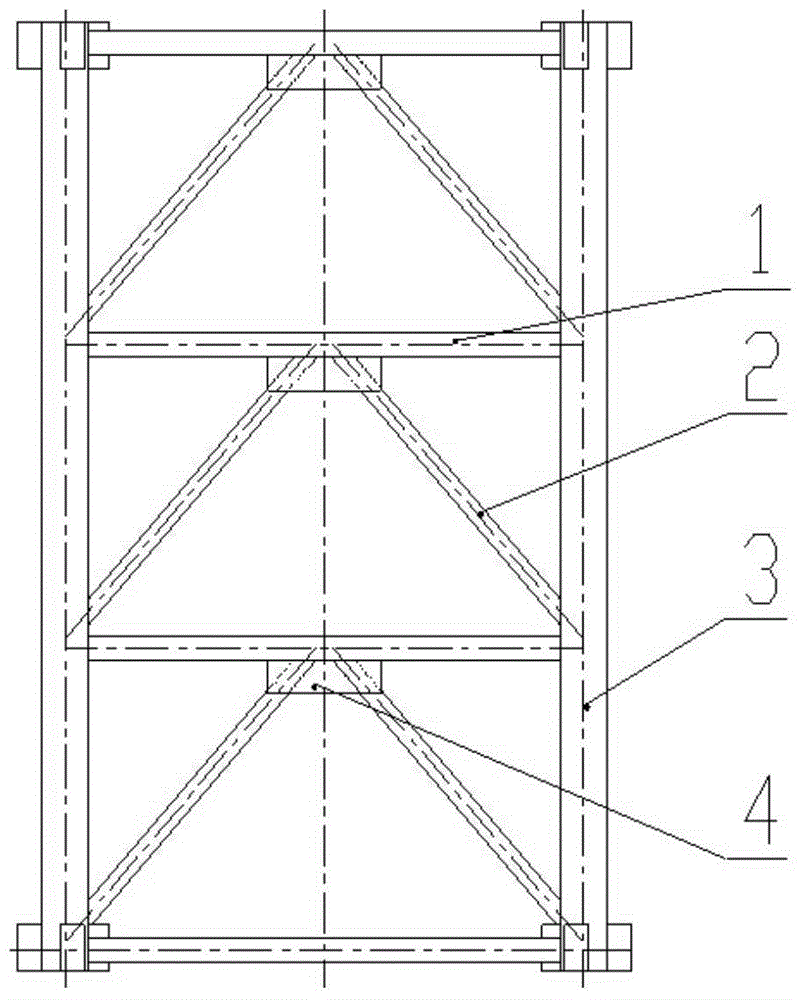

[0022] Such as figure 2 As shown, the standard section of the tower crane includes a main chord 3, and the main chord 3 is docked with four transverse webs 1, and the transverse webs 1 are uniformly fixed on the main chord 3 to form a closed frame respectively. One end of the diagonal web bar 2 in each frame is overlapped on the central position of the transverse web bar 1, and the other end of the diagonal web bar 2 is correspondingly overlapped at the junction of the transverse web bar 1 and the main chord bar 3, in each frame The two diagonal rods fixed inside are in the shape of a figure-eight. Wherein, the top end of the figure-eight diagonal bar 2 is welded to the transverse web bar 1 through the gusset plate 4 .

[0023] From figure 2 It can be seen that the tower crane standard section of the present invention optimizes the positions of the diagonal web bar 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com