Polishing machine for producing empty capsules

A hollow capsule and polishing machine technology, which is applied in the field of polishing machines, can solve the problems of uneven polishing treatment, broken hollow capsules, and inconvenient operation, and achieves the effects of simple structure, convenient operation, and avoiding secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

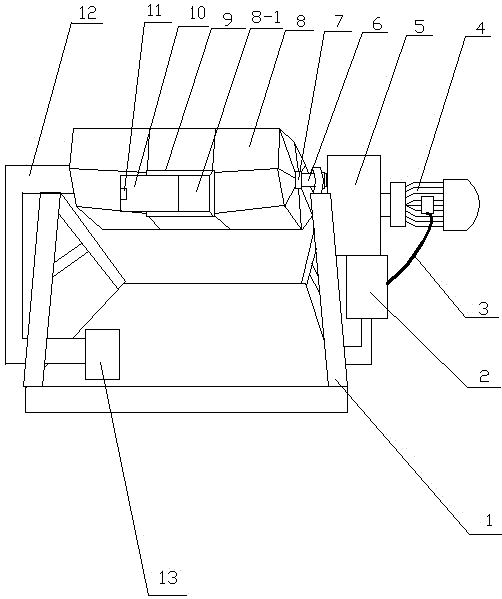

[0016] As shown in the drawings: a polishing machine for producing hollow capsules, including a polishing cylinder 8, a support frame 1, a motor 4, a transmission shaft 6, a transmission connection device 5, a vacuum cleaner 13, a dust suction pipe 12, and a transmission shaft 6 Both ends are installed on the upper end of the support frame 1, the motor 4 is fixedly installed on the right side of the support frame 1, the transmission shaft 6 passes through the polishing cylinder 8, the left end of the transmission shaft 6 is connected to the transmission connection device 5, and the motor 4 is fixedly installed On the right side of the transmission connection device 5, the polishing cylinder 8 is composed of two layers, the inner layer is a mesh structure, the outer layer is a solid structure, and there is a gap between the two layers; the polishing cylinder 8 is provided with an opening 8-1, The opening 8-1 is provided with a "U"-shaped pressure frame 9, and a chute is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com