Technology for repairing big-caliber concrete pipeline lining by utilizing thin wall stainless steel

A stainless steel and concrete technology, applied in the field of repair technology, can solve the problems of strict treatment of the concrete pipe wall to be repaired, the thickness of the stainless steel pipe cannot be determined, and the quality of the welded joint cannot be inspected, etc., to improve safety and adaptability, high strength, The effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

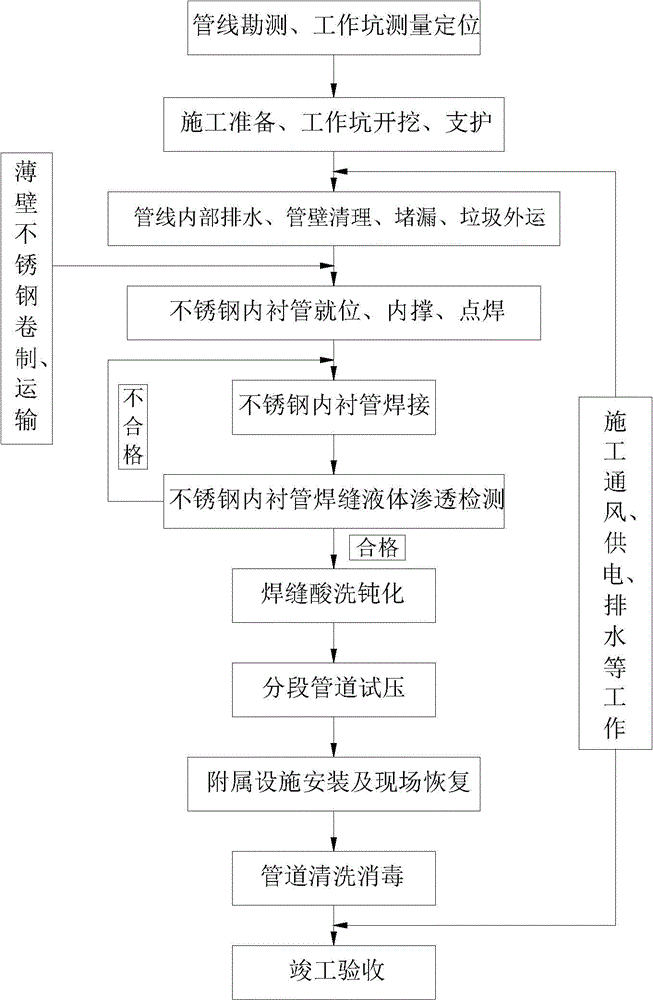

[0038] A repairing process for large-diameter concrete pipe lined with thin-walled stainless steel, comprising the following steps:

[0039] ⑴. Early pretreatment:

[0040] Including the following work: pipeline survey, working pit measurement and positioning; construction preparation, working pit excavation, support; pipeline internal drainage, pipe wall cleaning, leak plugging, and garbage transportation.

[0041] ⑵. Thin-wall stainless steel coiling and transportation:

[0042] Choose the most suitable stainless steel material and the most economical and reasonable thickness of lining stainless steel. The thin-walled stainless steel plate used for lining is the main material of austenitic stainless steel, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com