Waste heat utilization system using thermal desorption high temperature cycle spray wastewater to improve normal temperature desorption booth processing efficiency

A high-temperature cycle and normal-temperature desorption technology, applied in the field of contaminated soil treatment, can solve problems such as energy loss, high energy consumption, and technical failure to achieve the repair effect, and achieve the effects of small footprint, energy saving, and full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The above and other technical features and advantages of the present invention will be described in more detail below with reference to the accompanying drawings and embodiments.

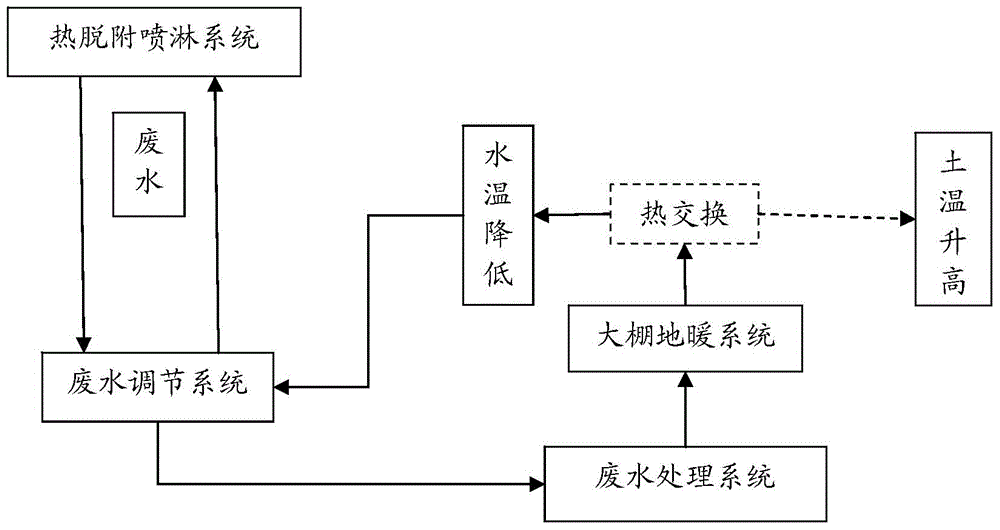

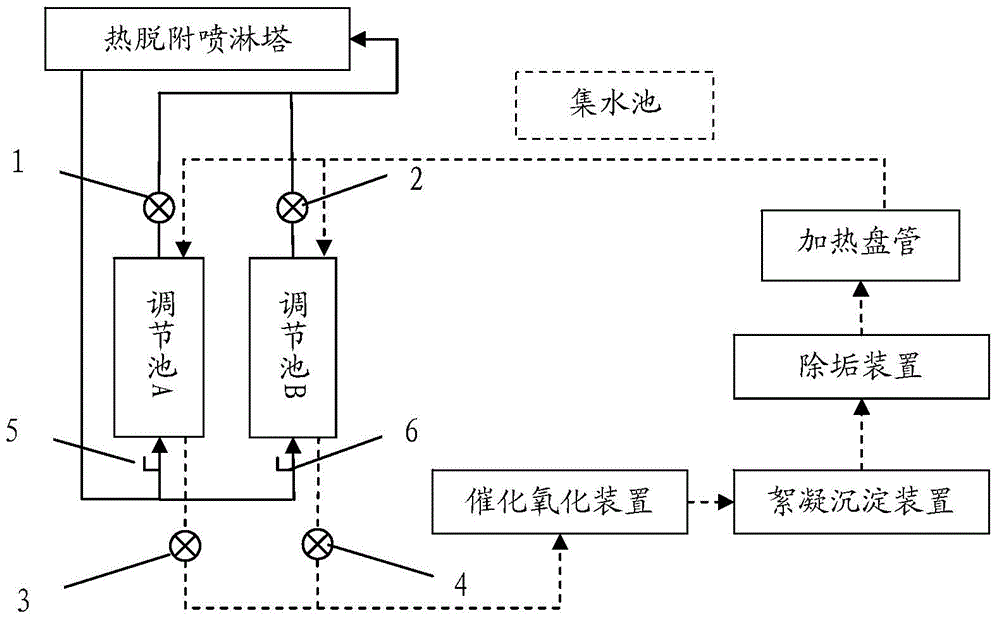

[0028] Such as figure 1 As shown, the present invention is a waste heat utilization system that uses thermal desorption high-temperature circulating spray wastewater to improve the treatment efficiency of normal temperature desorption greenhouses. The system includes a thermal desorption spray system, a wastewater adjustment system, a wastewater treatment system and a greenhouse floor heating system The thermal desorption spraying system is connected to the waste water regulating system, (it may also be that the thermal desorption spraying system and the waste water regulating system are interconnected to form a loop system) and the waste water regulating system is connected to the waste water treatment system. system, the wastewater treatment system is connected to the greenhouse floor heati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com