Novel atomizing spray nozzle

A technology of atomizing nozzles and nozzles, applied in the directions of spraying devices and spraying devices, can solve the problems of uneven distribution of spray surface density, affecting the performance of packed towers, difficult to control spray angles, etc., and achieve uniform spray surface density distribution. , Simple structure, low resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings and embodiments.

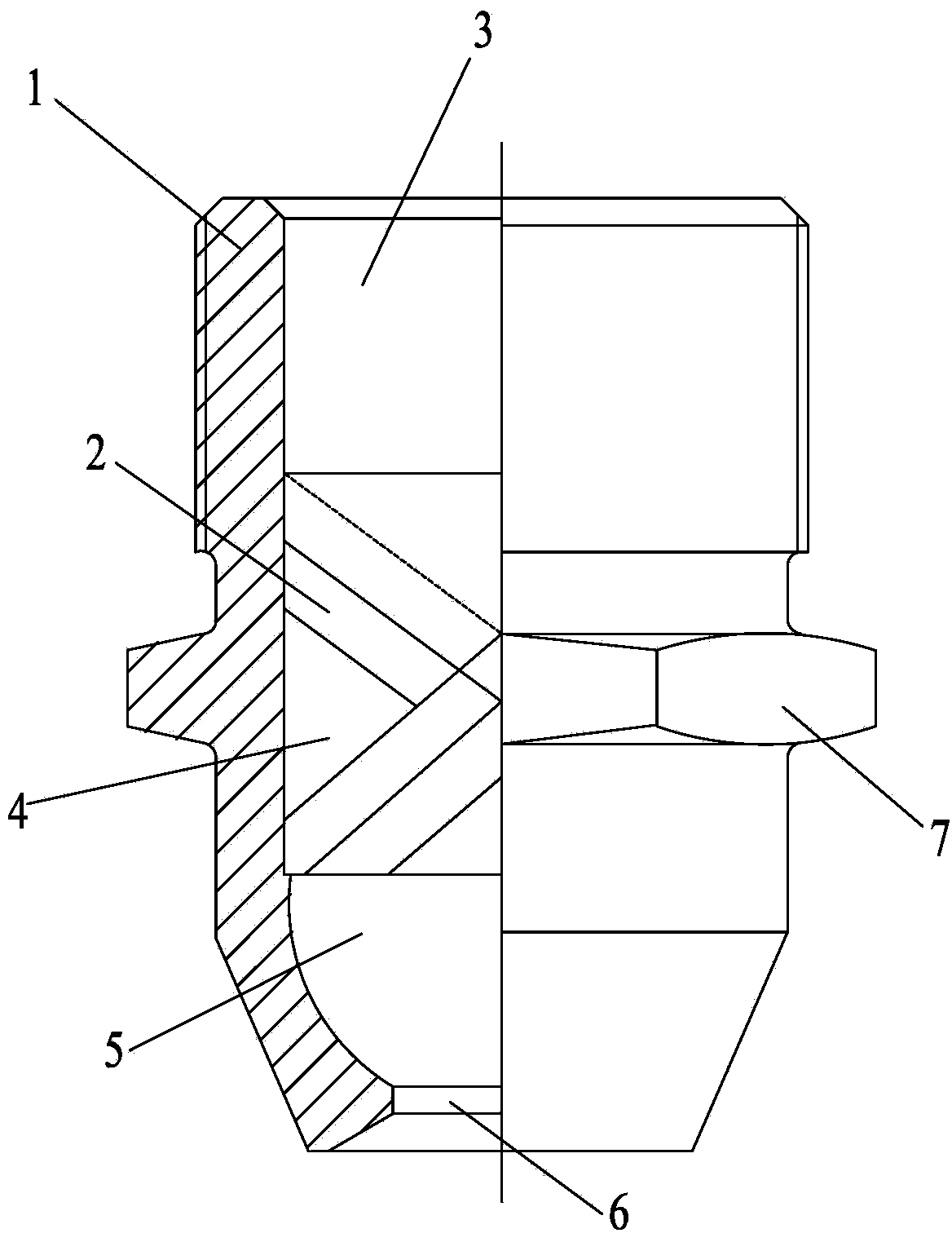

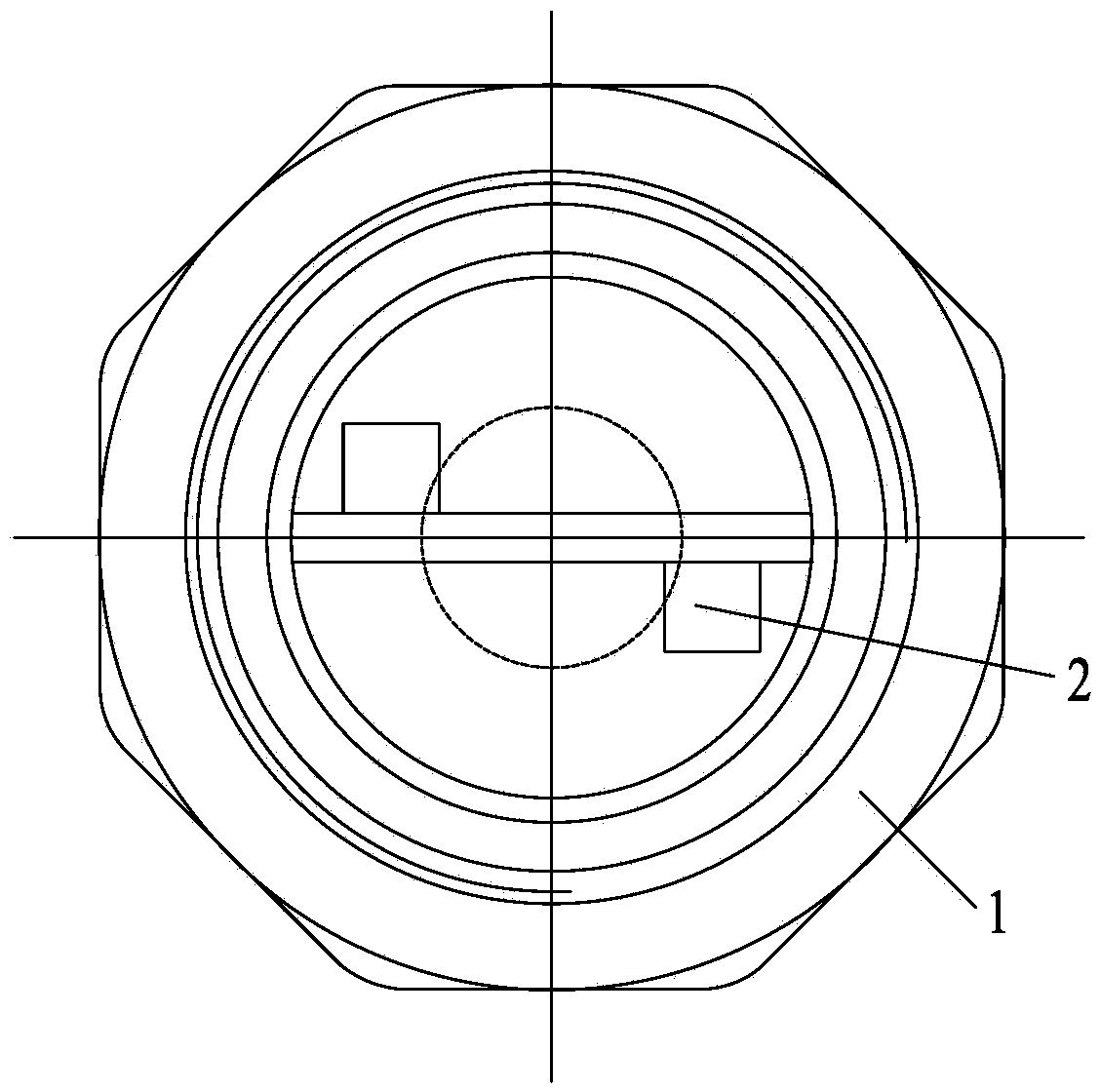

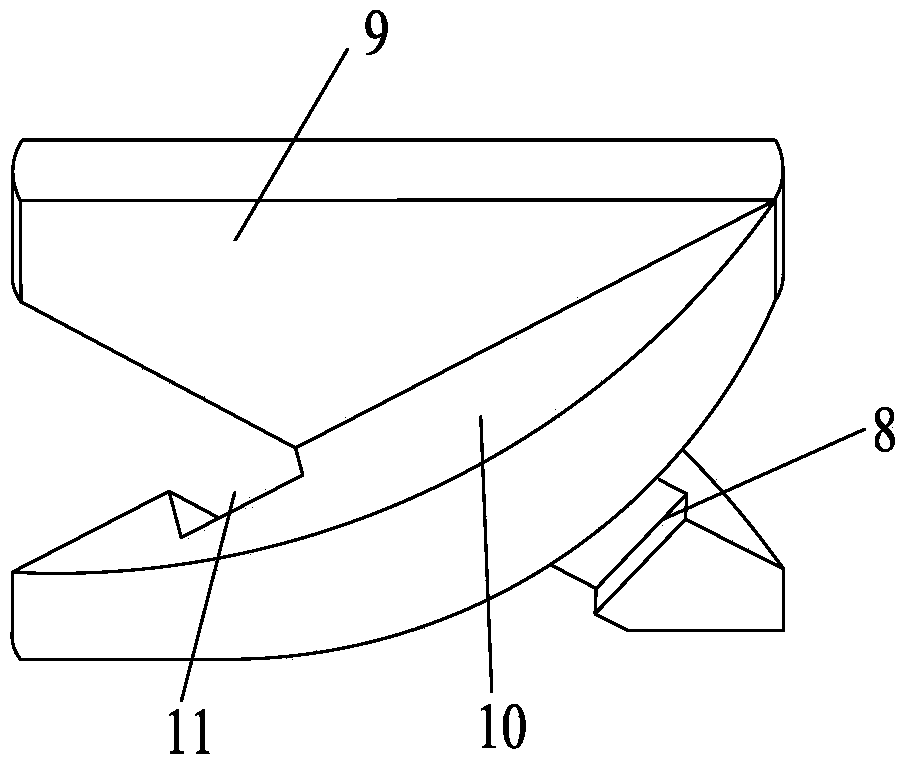

[0014] Such as figure 1 with figure 2 Shown: in order to make the operation more elastic, less resistance, larger spray angle, uniform spray surface density distribution, and dirt in the fluid is not easy to block, the present invention includes a nozzle housing 1; one end of the nozzle housing 1 forms a feed chamber 3, the other end of the spray head housing 1 forms a spray chamber 5, and an atomization chamber 4 is formed between the spray chamber 5 and the feed chamber 3; Optimized diversion chip 2.

[0015] Specifically, an internal thread is provided in the feed chamber 3, or an external thread is provided on the outer wall of the nozzle housing 1 corresponding to the feed chamber 3; the end of the nozzle housing 1 forming the feed chamber 3 is threaded to facilitate connection , the outer diameter of the guide chip 2 is consistent with the inner diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com