A method for generating a driving waveform of a thyristor rectifier and its driving circuit

A technology of thyristor driving and driving waveforms, which is applied in the direction of electrical components, output power conversion devices, AC power input conversion to DC power output, etc., can solve the problems of PWM waveforms not being synchronized, delay errors, etc., to improve working accuracy and Work stability, precise on-time control, high-precision wave effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

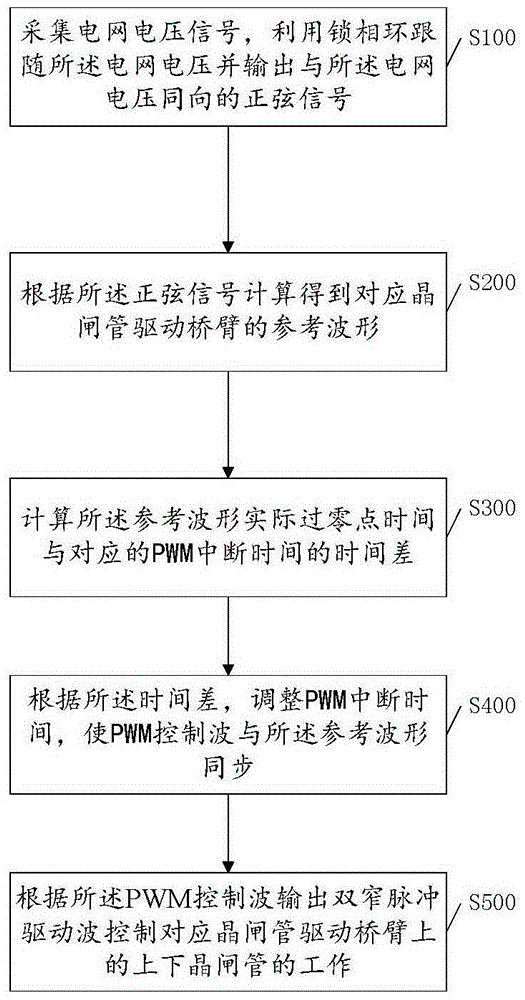

[0043] The drive signal of the thyristor generally has two forms, one is wide pulse trigger, and the other is double narrow pulse trigger. In the present invention, a wide pulse trigger signal is generated by a DSP, and a double narrow pulse driving signal can be generated after being combined by a CPLD. The specific embodiments are as follows figure 1 As shown, the present invention provides a method for generating a driving waveform of a thyristor rectifier, comprising:

[0044] Step S100, collecting a grid voltage signal, using a phase-locked loop to follow the grid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com