Gas density relay free of detachment in verification process

A gas density, relay technology, applied in circuits, electrical switches, electrical components, etc., to achieve the effects of small size, good sealing performance, and high environmental protection value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

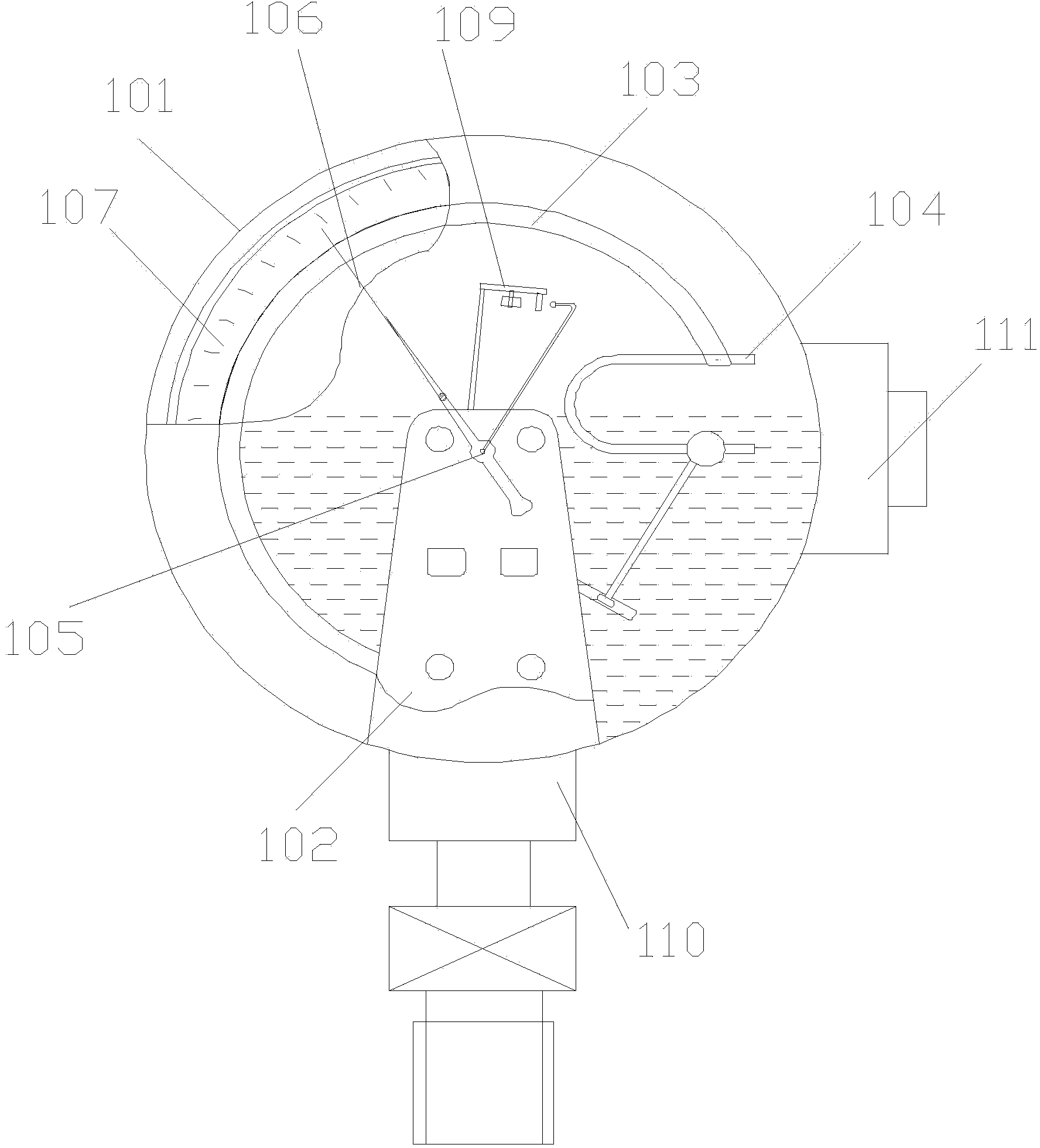

Embodiment 1

[0036] figure 2 It is a front view partial cross-sectional schematic diagram of a gas density relay according to Embodiment 1 of the present invention, such as figure 2 As shown, the disassembly-free gas density relay according to Embodiment 1 of the present invention includes: a housing 101, a base 102, a pressure detector 103, a temperature compensation element 104, and a core 105 disposed in the housing. , Pointer 106, Dial 107, End Block 108, Several Signal Generators 109, Equipment Connection Joint 110, and Verification Interface 2 and Valve 3. One end of the valve 3 communicates with the equipment connection joint 110, and the other end of the valve 3 communicates with the calibration port 2; the calibration port 2 communicates with the pressure detection port 2 through the base 102 Device 103 is connected. The verification interface 2 can be designed as a quick connection to further improve work efficiency.

[0037] Wherein, one end of the pressure detector 103 and...

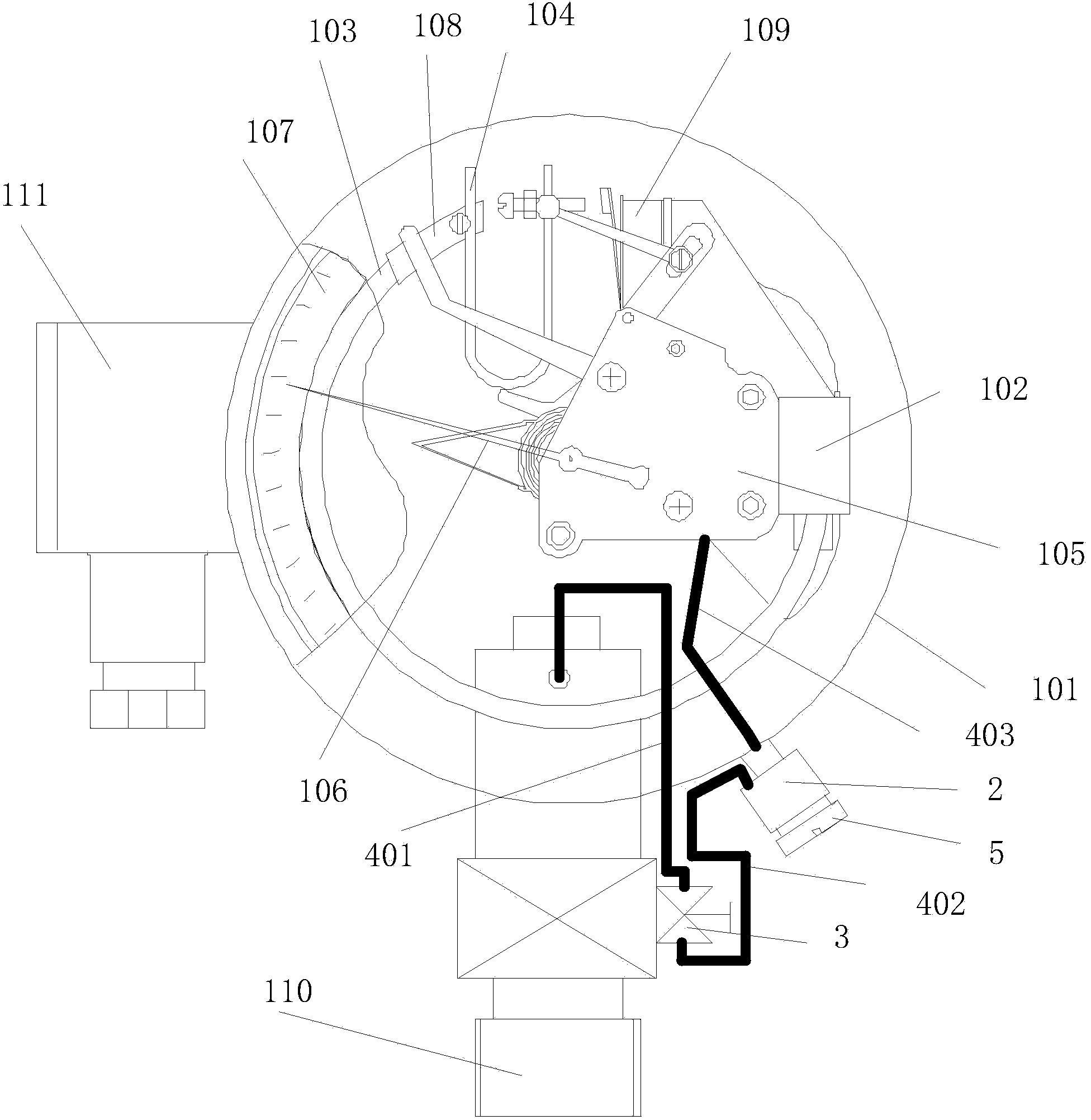

Embodiment 2

[0040] image 3 It is a front view partial cross-sectional schematic diagram of a gas density relay according to Embodiment 2 of the present invention, such as image 3 As shown, the verification interface 2 is fixed on the lower right corner of the housing 101 of the gas density relay, that is, below the terminal block 111, the valve 3 of the gas density relay is arranged on the equipment connection joint 110 of the gas density relay, and the verification interface 2 is set on the casing 101. On the gas circuit, one end of the valve 3 is connected to the equipment connection joint 110, the other end of the valve 3 is connected to the calibration port 2 through the gas circuit connector 402 of the calibration port, and the calibration port 2 is connected to the gas circuit connector 403 of the relay. The base 102 and the pressure detector 103 are connected. When the valve 3 is opened, the equipment connection joint 110 is connected with the base 102 and the pressure detector...

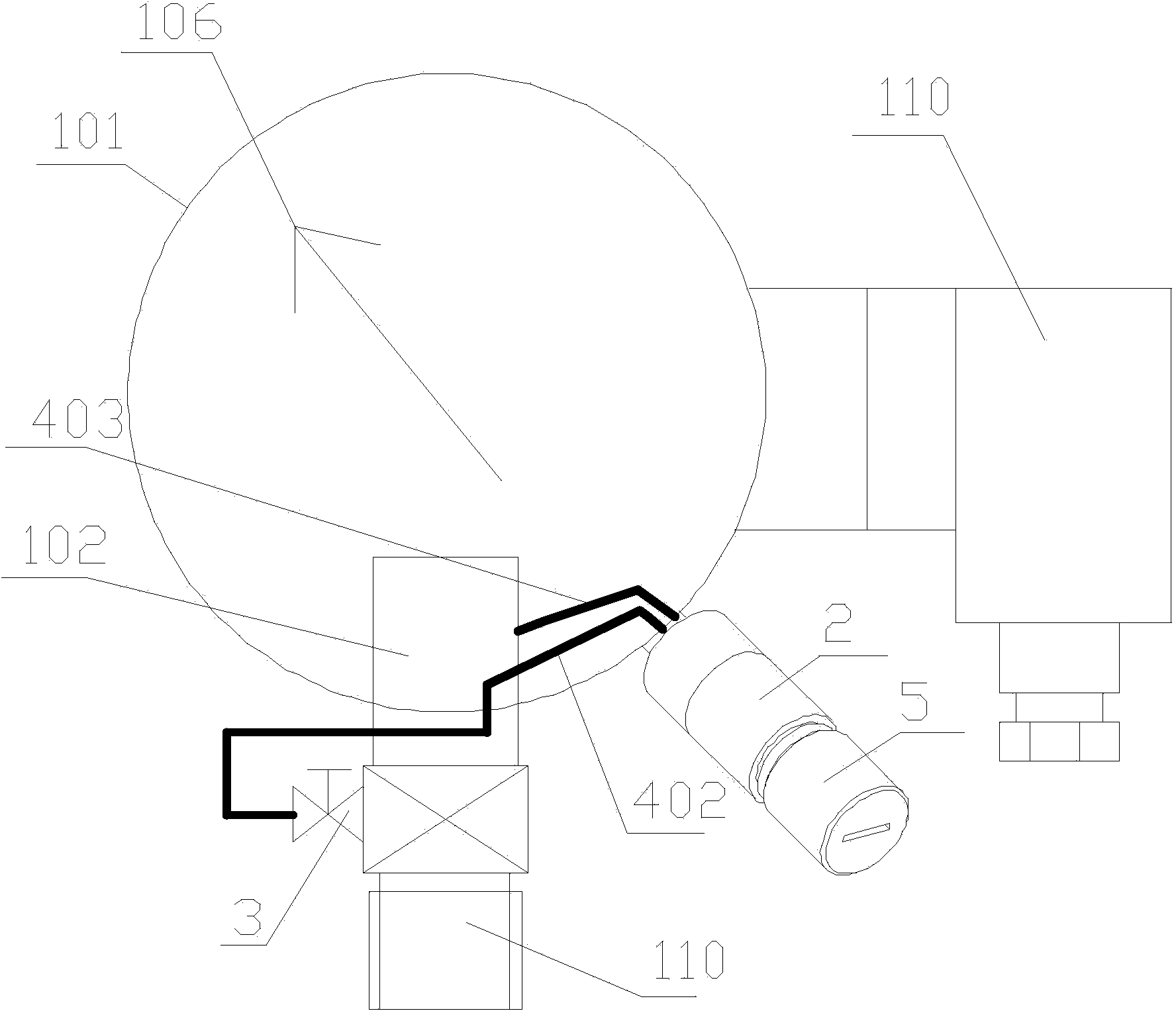

Embodiment 3

[0042] Figure 4 It is a front view partial cross-sectional schematic diagram of the gas density relay of Embodiment 3 of the present invention, as Figure 4 As shown, the verification interface 2 is fixed on the lower right corner of the housing 101 of the gas density relay, that is, below the wiring seat 111, the valve 3 of the gas density relay is arranged on the housing 101, and the verification interface 2 is arranged on the on the housing 101. On the air circuit, one end of the valve 3 communicates with the equipment connection joint 110 through the switch air circuit connector 401, and the other end of the valve 3 communicates with the calibration port 2 through the calibration interface gas circuit connector 402, and the calibration interface 2 passes through The relay air circuit connection part 403 communicates with the base 102 and the pressure detector 103 . When the valve 3 is opened, the equipment connection joint 110 is connected with the base 102 and the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com