Dynamic modeling method for reacting furnace in Claus sulfur recovery process

A technology of dynamic modeling and sulfur recovery, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems that the steady-state model is not enough to solve production problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

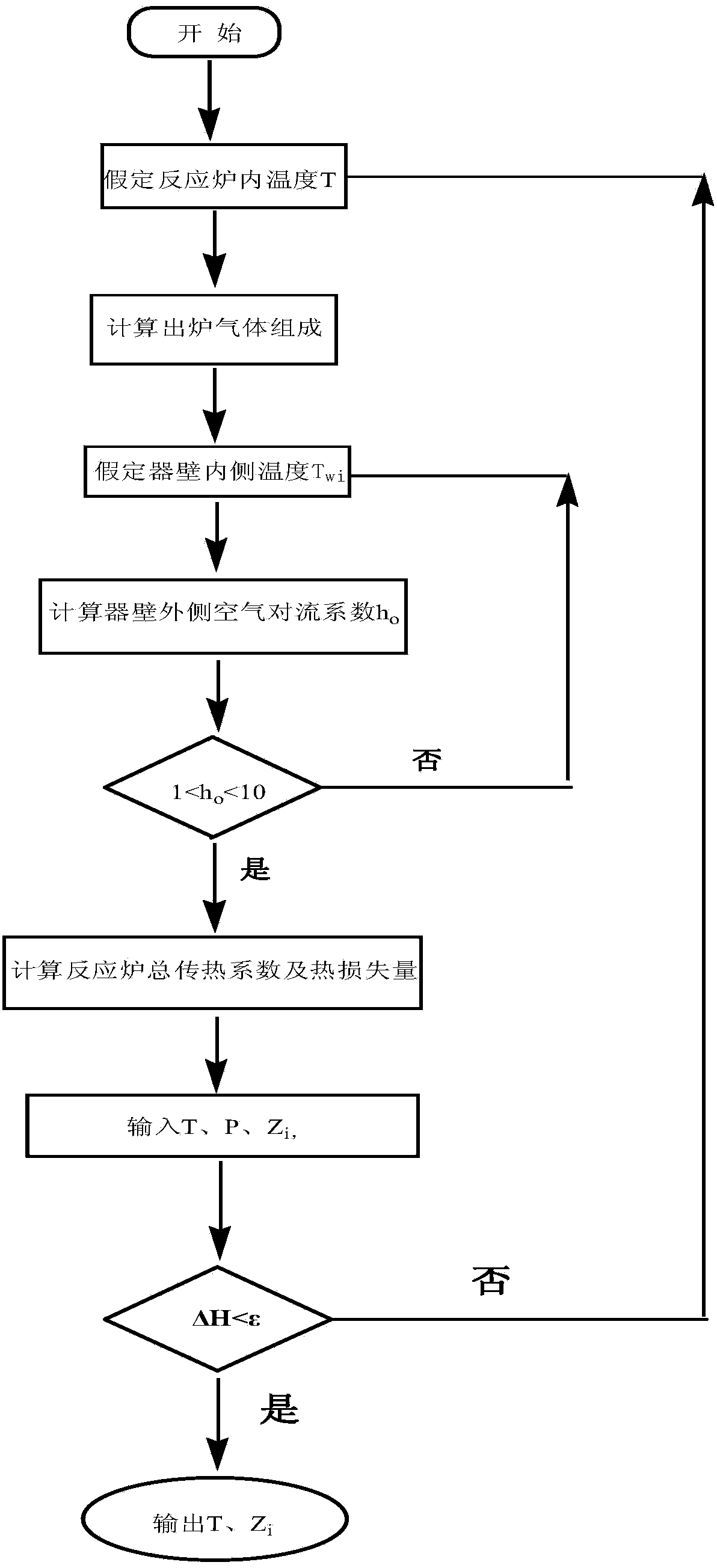

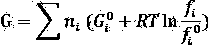

[0071] Such as figure 1 Shown, the object of the present invention is aimed at the reactor model in the Claus sulfur recovery process, proposed a kind of reactor dynamic modeling method in the Claus sulfur recovery process, the feed and discharge of reactor The condition is regarded as an unstable quantity, and the material composition inside the reactor at a certain temperature is solved according to the principle of atomic conservation and the minimum Gibbs free energy, and the heat loss is innovatively introduced into the energy balance equation, and the actual reactor is iterated through the balance equation temperature.

[0072] The acid gas involved in the Claus sulfur recovery process contains H 2 S, also contains CO 2 , N 2 and H 2 O, etc., acid gas from refinery gas, coke oven gas or water gas desulfurization unit may also contain NH 3 and HCN et al. Therefore, the actual reaction in the reaction furnace is very complicated, but the main reactions are as fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com