On-line detection system for preparing ethylene glycol with synthetic gas in industrial production

A detection system and synthesis gas technology, applied in transmission systems, electrical program control, measurement devices, etc., can solve problems such as poor safety and stability, low reaction efficiency, and lag in detection and analysis, and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

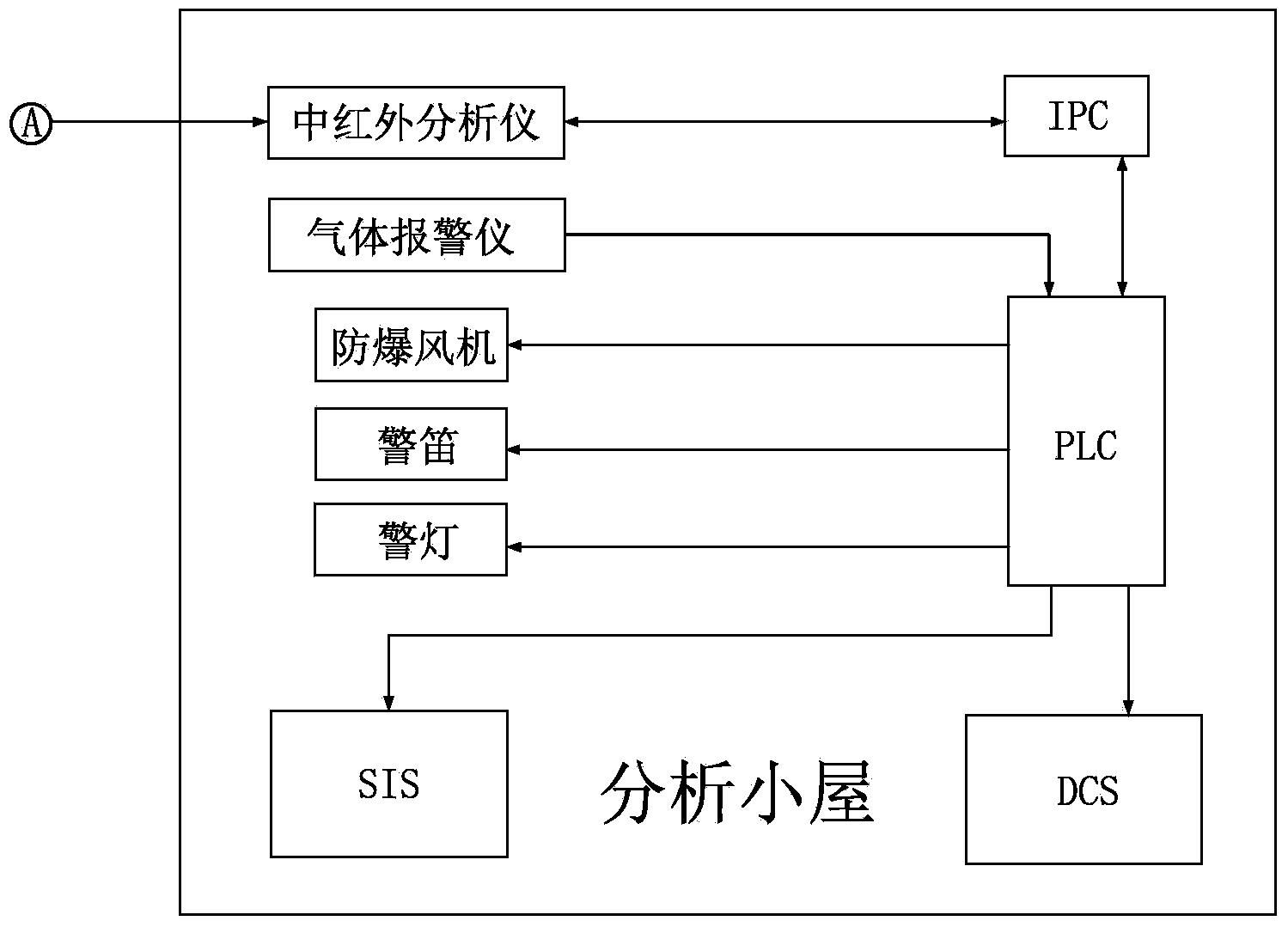

[0066] Such as figure 2 As shown, the gas on-line detection system for industrial production of ethylene glycol from syngas in this embodiment includes an analysis cabin, a mid-infrared analyzer, an IPC, a PLC, a DCS, a SIS, a gas alarm, an explosion-proof fan, a siren and a siren. lamp.

[0067] The following is the connection relationship of each device in this embodiment:

[0068] The mid-infrared analyzer, IPC, PLC, DCS, SIS, gas alarm, explosion-proof fan, siren and police lights are all placed in the analysis cabin; the mid-infrared analyzer is connected to the IPC with a network cable, and the data is transmitted through the LAN; the IPC and the PLC pass through The RS485 or RS232 communication interface is connected for data transmission; the signal output port of PLC is respectively connected with DCS, SIS, gas alarm, explosion-proof fan, siren and police light through hard wiring.

[0069] The following are the functions of each device in this embodiment:

[0070...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com