An Experimental Device for Measuring the Boiling Heat Transfer Coefficient of Flow in Refrigerant Tubes

A technology of boiling heat exchange and experimental equipment, applied in the direction of material thermal conductivity, material thermal development, etc., can solve the problems of increasing uncontrollable factors, increasing difficulty of measurement and control, and complicated experimental equipment, and achieves the effect of easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with the embodiments and the accompanying drawings. The following examples do not limit the present invention in any form, and all technical solutions obtained by means of equivalent replacement or equivalent transformation are within the protection scope of the present invention.

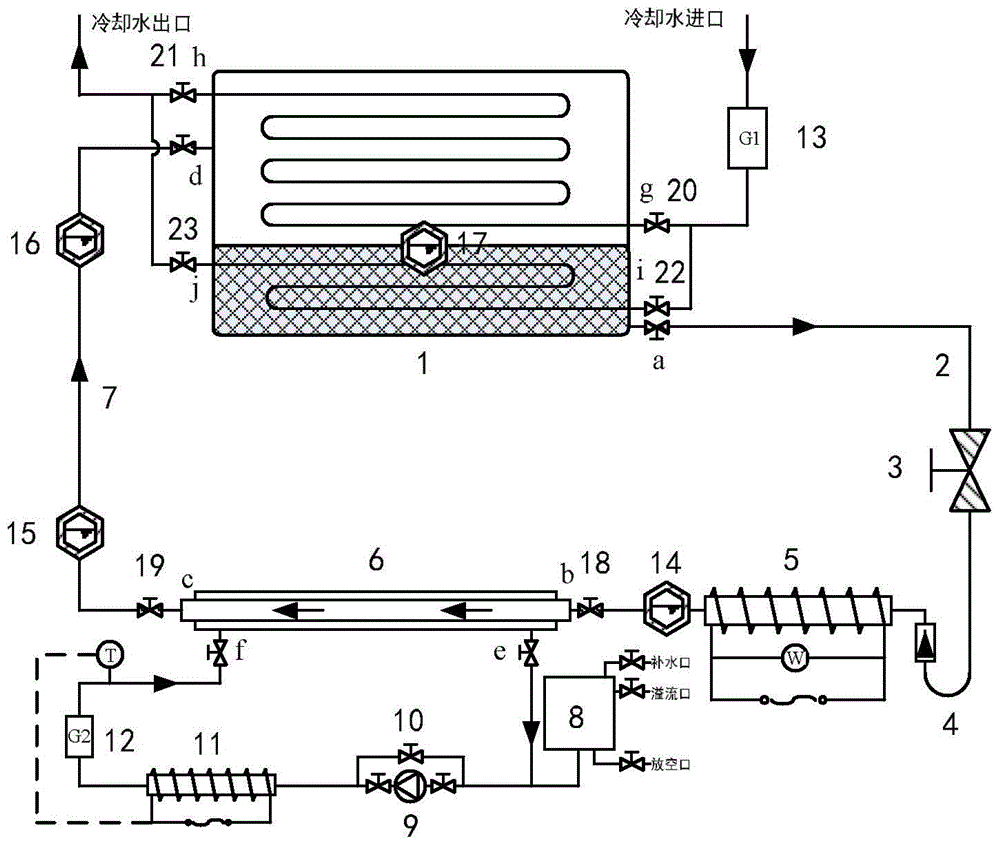

[0017] An experimental device for measuring the boiling heat transfer coefficient of refrigerant tube flow, such as figure 1 As shown, the device is composed of a refrigerant cycle ①, a hot water cycle ②, and a cooling water cycle ③.

[0018] The refrigerant cycle ① includes a condenser 1, a downcomer 2, a refrigerant flow regulating valve 3, a one-way valve 4, a refrigerant preheater 5, a first sight glass 14, a shut-off valve 18, a single-pipe evaporator 6, The shut-off valve 19, the second mirror 15, the rising pipe 7, and the third mirror 16 are connected in the following way: the liquid outlet a of the shell side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com