Method for detecting attenuation resistance characteristic of fluorescent powder

A detection method and phosphor technology, applied in the measurement of color/spectral characteristics, etc., can solve problems such as large attenuation, and achieve the effect of strong anti-attenuation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

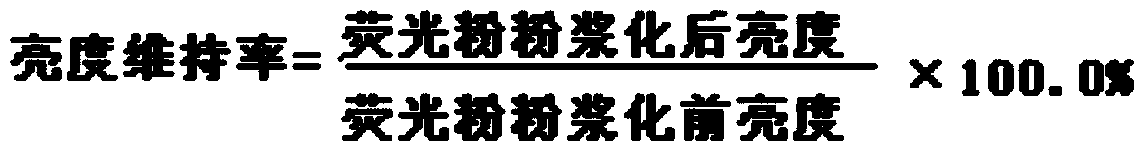

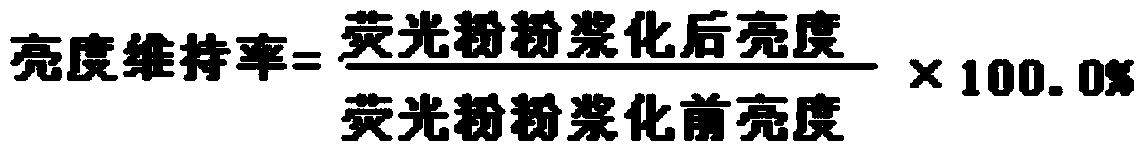

[0027] Example 1: Verification of different batches of products

[0028] Weigh 60 grams of three different batches of fluorescent powder to be tested, add them to 150 grams of hot pure water, the temperature of the pure water is 85 degrees Celsius, after stirring evenly, carry out ultrasonic dispersion respectively, ultrasonic power 200w, ultrasonic time After 3 minutes, the slurry is settled. After 3 hours of sedimentation, pour off the clarified liquid on the upper layer of the slurry, and put it into a dryer at 120 degrees Celsius for drying. After drying for 12 hours, take it out and let it cool, and pass through 120 mesh and 240 mesh respectively. Sieve each again. Sampling was carried out using a vacuum ultraviolet spectrometer to detect the brightness maintenance rate before and after slurrying.

Embodiment 2

[0029] Example 2: Method Consistency Verification

[0030] Weigh three portions of a fluorescent powder to be tested, 60 grams each, and add them to 150 grams of hot pure water. The temperature of the pure water is 85 degrees Celsius. After stirring evenly, carry out ultrasonic dispersion respectively. After 3 hours of sedimentation, pour off the clarified liquid on the upper layer of the slurry, and put it into a dryer at 120 degrees Celsius for drying. After drying for 12 hours, take it out and let it cool, and pass through 120 mesh and 240 mesh sieves respectively. Net each again. Sampling was carried out using a vacuum ultraviolet spectrometer to detect the brightness maintenance rate before and after slurrying.

Embodiment 3

[0031] Example 3: Range Verification 1

[0032] Weigh 50 grams of two different batches of fluorescent powder to be tested, respectively, add them to 150 grams of hot pure water, the temperature of the pure water is 80 degrees Celsius, after stirring evenly, carry out ultrasonic dispersion respectively, ultrasonic power 200w, ultrasonic time After 3 minutes, the slurry is settled. After 3 hours of settlement, pour off the clarified liquid on the upper layer of the slurry, and put it into a dryer at 100 degrees Celsius for drying. After drying for 8 hours, take it out and let it cool, and pass through 120 mesh and 240 mesh respectively. Sieve each again. Sampling was carried out using a vacuum ultraviolet spectrometer to detect the brightness maintenance rate before and after slurrying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com