Static diaphragm coupler angular deviation fatigue testing bed

A diaphragm coupling and angular offset technology, which is applied in the field of fatigue test benches, can solve the problems of difficulty in ensuring the accuracy of angular offset and cumbersome adjustment of limit angular offset, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

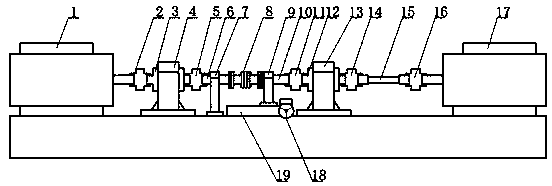

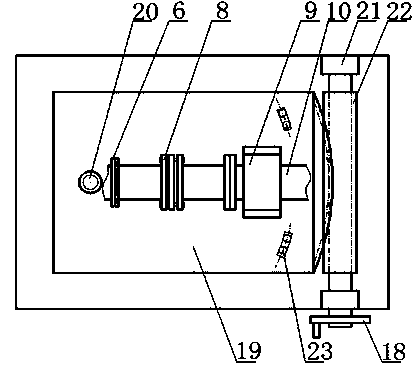

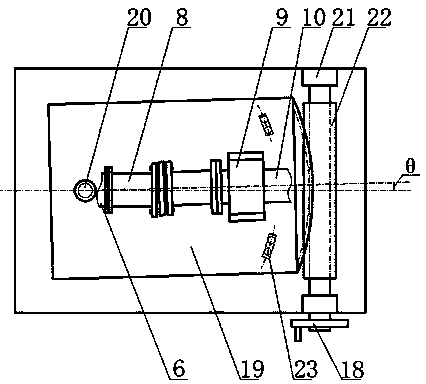

[0016] like figure 1 As shown, the present invention adopts the diaphragm coupling that first adjusts the static angular deviation of the diaphragm coupling and then adjusts the angular deviation in place when performing the static angular deflection fatigue test on the diaphragm coupling. Methods of performing fatigue tests. The test bench is composed of two parts: the diaphragm coupling test mechanism and the diaphragm coupling angular offset adjustment mechanism. The diaphragm coupling test mechanism includes the frequency conversion main input motor 1, the first coupling 2, the first torque Instrument 3, first torque meter support 4, second coupling 5, first transmission shaft 6, first rolling bearing support 7, tested diaphragm coupling 8, second transmission shaft 10, third coupling 11 , the second torque meter 12, the second torque meter bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com