Vehicle oil filler cover online detection tool

A fuel filler cap and fuel filler technology, applied to measuring devices, instruments, mechanical devices, etc., can solve problems such as coordination, vehicle repair, and affecting work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the technical solution of the present invention, the solution will be further described in detail below in conjunction with specific embodiments.

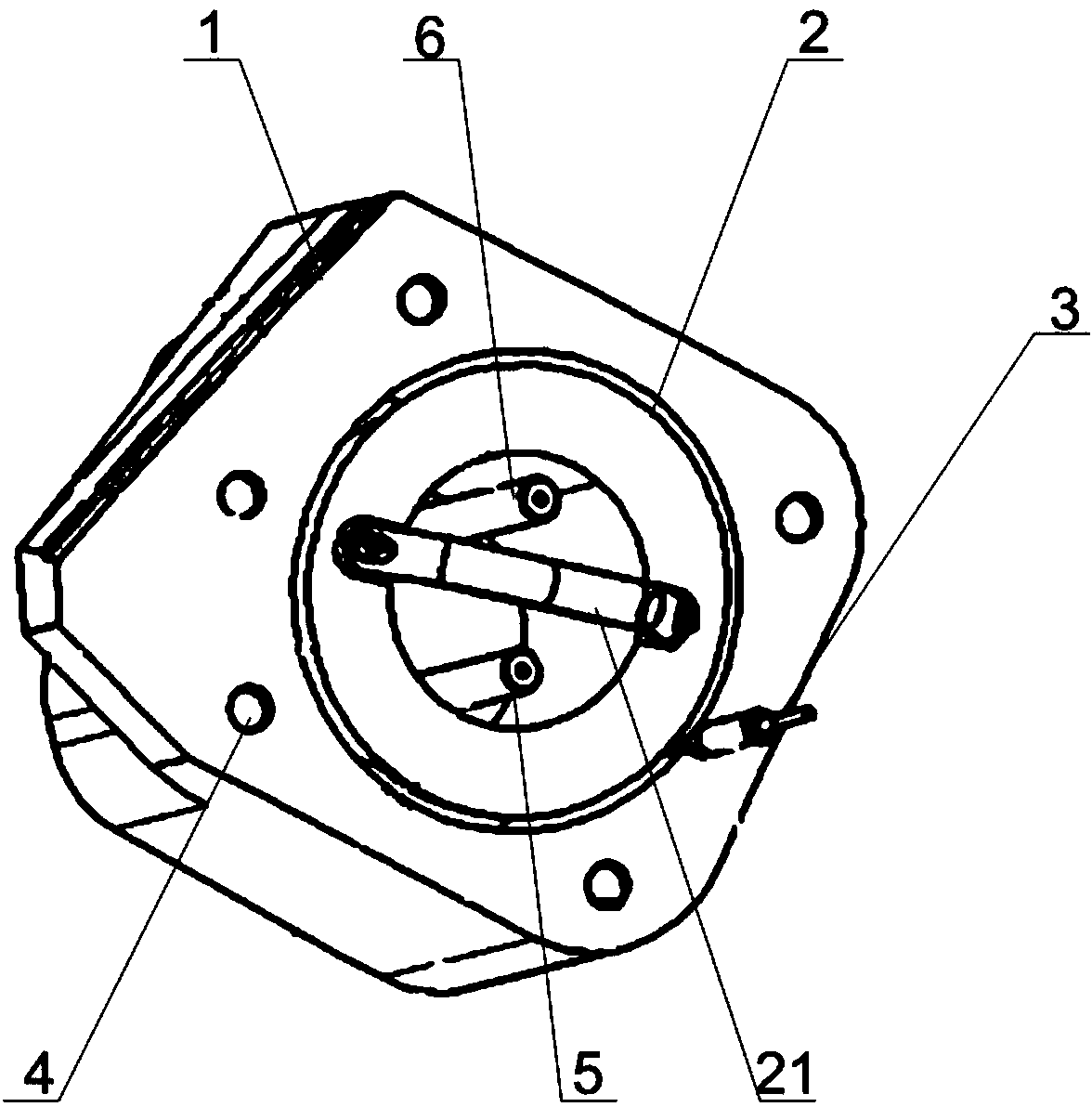

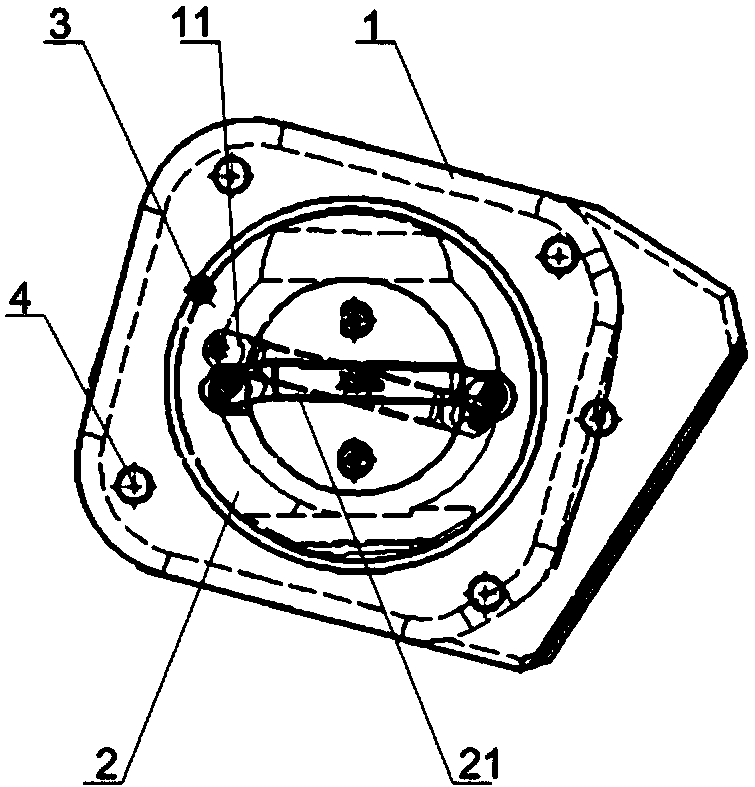

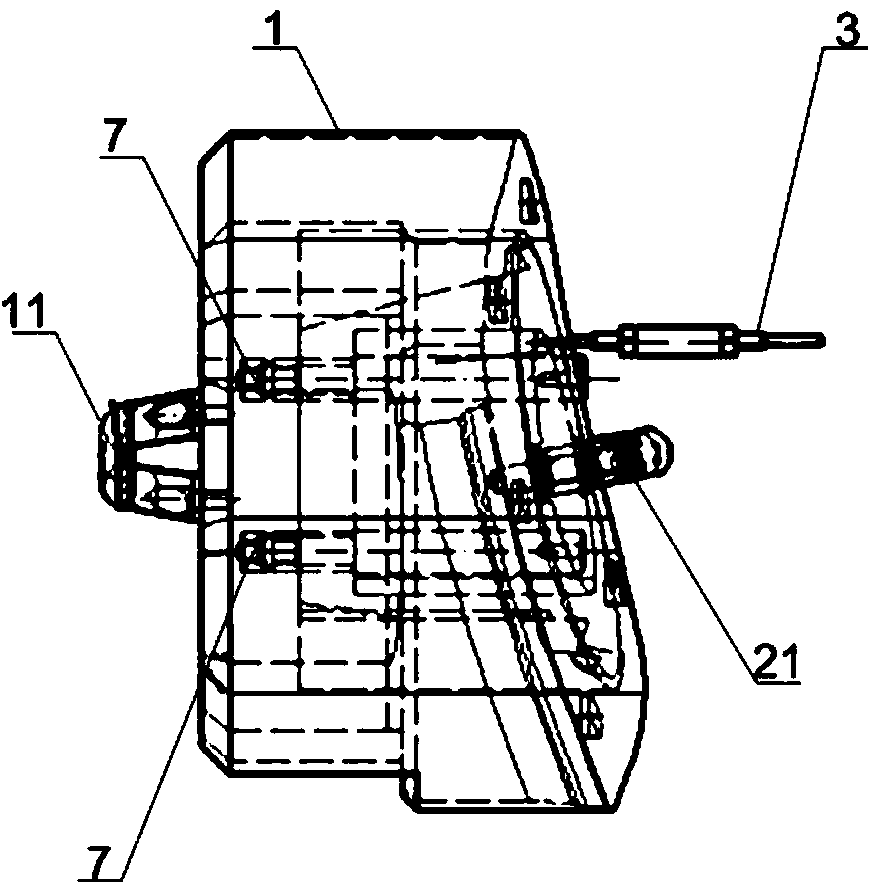

[0025] like Figure 1~3 As shown, the present invention provides an online inspection tool for the fuel filler cap of an automobile, which is used to check the size of the fuel filler on the side panel after the side outer panel of the automobile is put online. The online inspection tool for the fuel filler cap of the automobile includes a Block 1, convex detection block 2 and go-no-go gauge 3, the concave detection block 1 and the convex detection block 2 are magnetic detection blocks, magnetic hard resin detection blocks can be selected, the weight is lighter, and it is convenient to use; The detection block 1 is provided with an accommodating space for the convex detection block 2, and the upper and lower surfaces of the concave detection block 1 are provide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com